- •CONTENTS

- •FOREWORD

- •INTRODUCTION

- •SUMMARY OF CHANGES

- •100 GENERAL

- •102 DESIGN CRITERIA

- •103 CRITERIA FOR PRESSURE DESIGN OF PIPING COMPONENTS

- •104 PRESSURE DESIGN OF COMPONENTS

- •105 PIPE

- •106 FITTINGS, BENDS, AND INTERSECTIONS

- •107 VALVES

- •108 PIPE FLANGES, BLANKS, FLANGE FACINGS, GASKETS, AND BOLTING

- •110 PIPING JOINTS

- •111 WELDED JOINTS

- •112 FLANGED JOINTS

- •113 EXPANDED OR ROLLED JOINTS

- •114 THREADED JOINTS

- •115 FLARED, FLARELESS, AND COMPRESSION JOINTS, AND UNIONS

- •116 BELL END JOINTS

- •117 BRAZED AND SOLDERED JOINTS

- •118 SLEEVE COUPLED AND OTHER PROPRIETARY JOINTS

- •119 EXPANSION AND FLEXIBILITY

- •120 LOADS ON PIPE SUPPORTING ELEMENTS

- •121 DESIGN OF PIPE SUPPORTING ELEMENTS

- •122 DESIGN REQUIREMENTS PERTAINING TO SPECIFIC PIPING SYSTEMS

- •123 GENERAL REQUIREMENTS

- •124 LIMITATIONS ON MATERIALS

- •125 MATERIALS APPLIED TO MISCELLANEOUS PARTS

- •126 MATERIAL SPECIFICATIONS AND STANDARDS FOR STANDARD AND NONSTANDARD PIPING COMPONENTS

- •127 WELDING

- •128 BRAZING AND SOLDERING

- •129 BENDING AND FORMING

- •130 REQUIREMENTS FOR FABRICATING AND ATTACHING PIPE SUPPORTS

- •131 WELDING PREHEAT

- •132 POSTWELD HEAT TREATMENT

- •133 STAMPING

- •135 ASSEMBLY

- •136 INSPECTION AND EXAMINATION

- •137 PRESSURE TESTS

- •138 GENERAL

- •139 OPERATION AND MAINTENANCE PROCEDURES

- •140 CONDITION ASSESSMENT OF CPS

- •141 CPS RECORDS

- •Figures

- •Tables

- •102.4.3 Longitudinal Weld Joint Efficiency Factors

- •MANDATORY APPENDICES

- •Table A-4 Nickel and High Nickel Alloys

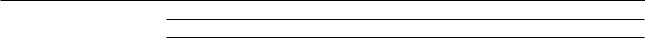

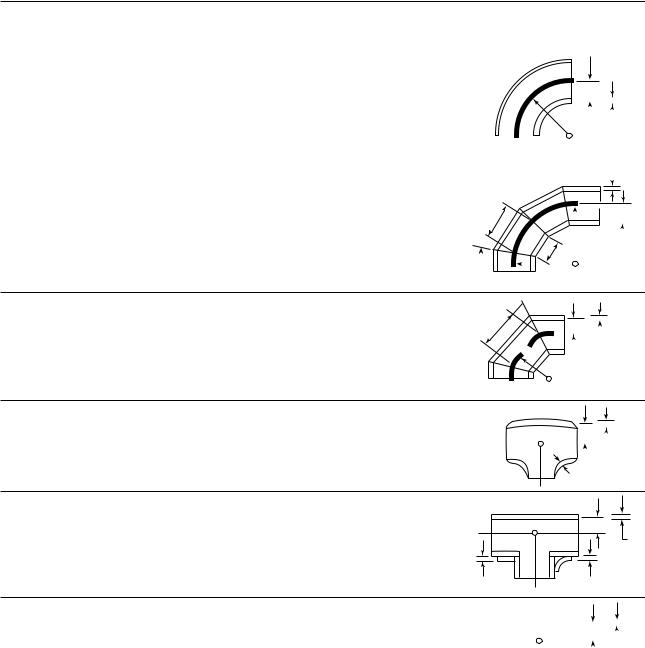

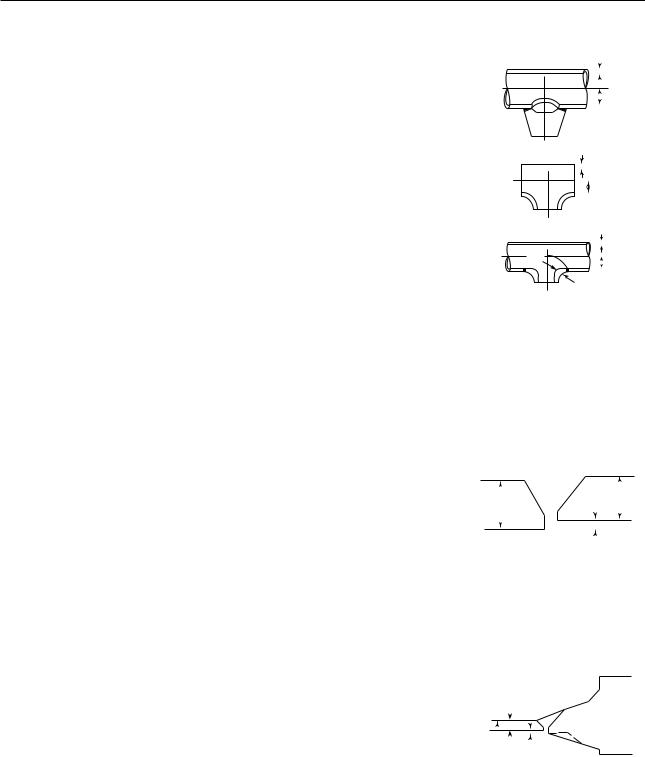

- •Chart D-1 Flexibility Factor, k, and Stress Intensification Factor, i

- •Chart D-2 Correction Factor, c

- •Fig. D-1 Branch Connection Dimensions

- •NONMANDATORY APPENDICES

- •INDEX

- •ASME B31.1 INTERPRETATIONS VOLUME 45

- •B31.1 — Cases No. 35

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys

Maximum Allowable Stress Values in Tension, ksi, for Metal Temperature, °F, Not Exceeding |

|

|

−20 |

UNS |

|

to |

Alloy |

Spec. |

100 200 300 400 500 600 650 700 750 800 850 900 950 1,000 1,050 1,100 1,150 1,200 |

No. |

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seamless Pipe and Tube |

||

10.0 |

10.0 |

10.0 |

10.0 |

10.0 |

10.0 . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N02200 |

B 161 |

|||||||

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N02200 |

|

|||||||

18.6 |

18.6 |

18.6 |

18.6 |

18.3 |

17.7 . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N02200 |

|

|||||||

8.0 |

7.7 |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

7.4 |

7.4 |

7.2 |

5.8 |

4.5 |

3.7 |

3.0 |

2.4 |

2.0 |

1.5 |

1.2 |

N02201 |

B 161 |

6.7 |

6.4 |

6.3 |

6.2 |

6.2 |

6.2 |

6.2 |

6.2 |

6.1 |

6.0 |

5.8 |

4.5 |

3.7 |

3.0 |

2.4 |

2.0 |

1.5 |

1.2 |

N02201 |

|

17.1 |

17.1 |

17.0 |

17.0 |

16.8 |

16.3 . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N02201 |

|

|||||||

20.0 |

18.5 |

17.8 |

17.2 |

16.8 |

16.3 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.1 |

14.9 |

14.7 |

14.5 |

13.0 |

9.8 |

6.6 |

N08800 |

B 163 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

19.9 |

17.0 |

13.0 |

9.8 |

6.6 |

N08800 |

|

16.7 |

15.4 |

14.4 |

13.6 |

12.9 |

12.2 |

11.9 |

11.6 |

11.4 |

11.1 |

10.9 |

10.7 |

10.5 |

10.4 |

10.2 |

10.0 |

9.3 |

7.4 |

N08810 |

|

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.1 |

15.7 |

15.3 |

15.0 |

14.7 |

14.5 |

14.2 |

14.0 |

13.8 |

11.6 |

9.3 |

7.4 |

N08810 |

|

18.7 |

16.4 |

15.2 |

14.7 |

14.7 |

14.7 |

14.7 |

14.6 |

14.5 |

14.3 |

11.0 |

8.0 . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N04400 |

B 165 |

|

16.7 |

14.6 |

13.6 |

13.2 |

13.1 |

13.1 |

13.1 |

13.0 |

12.9 |

12.7 |

11.0 |

8.0 . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N04400 |

|

|

24.3 |

24.3 |

24.3 |

24.3 |

24.3 . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N04400 |

|

||||||||

20.0 |

19.1 |

18.3 |

17.5 |

16.8 |

16.2 |

15.9 |

15.7 |

15.5 |

15.2 |

15.1 |

14.9 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

B 167 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

16.7 |

15.9 |

15.2 |

14.6 |

14.0 |

13.5 |

13.3 |

13.1 |

12.9 |

12.7 |

12.5 |

12.4 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

22.9 |

21.3 |

20.8 |

20.5 |

20.2 |

19.9 |

19.8 |

19.6 |

19.4 |

19.1 |

18.7 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

B 167 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.4 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

20.0 |

19.1 |

18.3 |

17.5 |

16.8 |

16.2 |

15.9 |

15.7 |

15.5 |

15.2 |

15.1 |

14.9 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

23.3 |

20.8 |

19.2 |

18.1 |

17.2 |

16.6 |

16.4 |

16.2 |

16.0 |

15.9 |

15.8 |

15.7 |

15.6 |

15.5 |

15.4 |

15.4 |

15.3 |

15.3 |

N06617 |

B 167 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

22.5 |

22.1 |

21.9 |

21.7 |

21.5 |

21.3 |

21.2 |

21.0 |

20.9 |

20.9 |

20.8 |

20.7 |

18.1 |

N06617 |

|

20.0 |

18.5 |

17.8 |

17.2 |

16.8 |

16.3 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.1 |

14.9 |

14.7 |

14.5 |

13.0 |

9.8 |

6.6 |

N08800 |

B 407 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

19.9 |

17.0 |

13.0 |

9.8 |

6.6 |

N08800 |

|

16.7 |

15.4 |

14.4 |

13.6 |

12.9 |

12.2 |

11.9 |

11.6 |

11.4 |

11.1 |

10.9 |

10.7 |

10.5 |

10.4 |

10.2 |

10.0 |

9.3 |

7.4 |

N08810 |

|

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.5 |

16.1 |

15.7 |

15.3 |

15.0 |

14.7 |

14.5 |

14.2 |

14.0 |

13.8 |

11.6 |

9.3 |

7.4 |

N08810 |

|

23.3 |

21.4 |

20.3 |

19.4 |

18.5 |

17.8 |

17.5 |

17.3 |

17.2 |

17.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08825 |

B 423 |

|||

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.2 |

23.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08825 |

|

|||

26.7 |

24.9 |

23.6 |

22.6 |

21.8 |

21.1 |

20.8 |

20.6 |

20.3 |

20.1 |

20.0 |

19.8 |

19.7 |

19.5 |

19.4 |

19.4 |

19.3 |

19.3 |

N06625 |

B 444 |

34.3 |

34.3 |

34.3 |

33.6 |

32.9 |

32.4 |

32.1 |

31.8 |

31.5 |

31.2 |

30.9 |

30.6 |

30.3 |

29.9 |

29.5 |

29.0 |

21.0 |

13.2 |

N06625 |

|

28.6 |

26.7 |

24.6 |

22.9 |

21.5 |

20.4 |

20.0 |

19.6 |

19.3 |

19.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

B 622 |

|||

28.6 |

28.6 |

28.2 |

27.2 |

26.5 |

26.0 |

25.8 |

25.6 |

25.4 |

25.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

|

|||

27.3 |

24.9 |

23.0 |

21.3 |

19.9 |

18.8 |

18.2 |

17.8 |

17.4 |

17.1 |

16.9 |

16.7 |

16.6 |

16.5 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

27.3 |

27.3 |

27.3 |

27.3 |

26.9 |

25.2 |

24.6 |

24.0 |

23.5 |

23.1 |

22.8 |

22.6 |

22.4 |

22.3 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

28.6 |

25.6 |

23.1 |

21.3 |

20.1 |

19.3 |

18.9 |

18.7 |

18.4 |

18.2 |

18.0 |

17.8 |

17.6 |

17.5 |

17.3 |

17.1 |

16.9 |

13.6 |

R30556 |

|

28.6 |

28.6 |

28.0 |

27.1 |

26.4 |

26.0 |

25.6 |

25.2 |

24.9 |

24.6 |

24.3 |

24.1 |

23.8 |

23.6 |

23.3 |

21.2 |

17.0 |

13.6 |

R30556 |

|

24.9 |

23.2 |

21.3 |

19.8 |

18.3 |

17.3 |

17.0 |

16.9 |

16.9 |

16.9 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

B 677 |

|||

24.9 |

24.9 |

23.9 |

23.0 |

22.1 |

21.4 |

21.1 |

20.8 |

20.4 |

20.1 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

|

|||

26.9 |

24.1 |

21.5 |

19.7 |

18.7 |

18.0 |

17.7 |

17.5 |

17.4 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

26.9 |

26.9 |

26.2 |

24.8 |

23.7 |

22.8 |

22.4 |

22.0 |

21.6 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

--`,,```````,,```,`,`,,,,`,`,`,`-`-`,,`,,`,`,,`---

165

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

|

|

|

|

Specified |

Specified |

|

|

UNS |

|

|

|

|

Minimum |

Minimum |

E |

Spec. |

Alloy |

Temper or |

Nominal |

P- |

|

Tensile, |

Yield, |

or |

No. |

No. |

Condition |

Composition |

No. |

Notes |

ksi |

ksi |

F |

|

|

|

|

|

|

|

||

Seamless Pipe and Tube (Cont’d) |

|

|

|

|

|

|

||

B 690 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(22) |

95 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(21) |

100 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(21) |

100 |

45 |

1.00 |

B 729 |

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

1.00 |

|

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

1.00 |

Welded Pipe and Tube |

|

|

|

|

|

|

|

|

B 464 |

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

0.85 |

|

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

0.85 |

B 468 |

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

0.85 |

|

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

0.85 |

B 546 |

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(7) |

95 |

35 |

0.85 |

|

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(2)(7) |

95 |

35 |

0.85 |

B 619 |

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(12) |

100 |

45 |

0.85 |

|

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(2)(12) |

100 |

45 |

0.85 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12) |

100 |

41 |

0.85 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12) |

100 |

41 |

0.85 |

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1) |

100 |

45 |

0.85 |

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2) |

100 |

45 |

0.85 |

B 626 |

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(12) |

100 |

45 |

0.85 |

|

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(2)(12) |

100 |

45 |

0.85 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12) |

100 |

41 |

0.85 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12) |

100 |

41 |

0.85 |

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1) |

100 |

45 |

0.85 |

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2) |

100 |

45 |

0.85 |

B 673 |

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1) |

87 |

43 |

0.85 |

|

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1)(2) |

87 |

43 |

0.85 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

45 |

(1)(19)(20) |

94 |

43 |

0.85 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

45 |

(1)(2)(19)(20) |

94 |

43 |

0.85 |

B 674 |

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1) |

87 |

43 |

0.85 |

|

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1)(2) |

87 |

43 |

0.85 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

45 |

(1)(19)(20) |

94 |

43 |

0.85 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

45 |

(1)(2)(19)(20) |

94 |

43 |

0.85 |

B 675 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(22) |

95 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(21) |

100 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(21) |

100 |

45 |

0.85 |

B 676 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(22) |

95 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(21) |

100 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(21) |

100 |

45 |

0.85 |

166

--`,,```````,,```,`,`,,,,`,`,`,`-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

Maximum Allowable Stress Values in Tension, ksi, for Metal Temperature, °F, Not Exceeding |

|

|

|

||||||||||||||

−20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNS |

|

to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alloy |

Spec. |

100 |

200 |

300 |

400 |

500 |

600 |

650 |

700 |

750 |

800 |

850 |

900 |

950 |

1,000 |

1,050 |

1,100 |

1,150 |

1,200 |

No. |

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seamless Pipe and Tube (Cont’d) |

|||

27.1 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 690 |

|||

27.1 |

27.1 |

25.7 |

24.6 |

23.8 |

23.3 |

23.1 |

22.9 |

22.8 |

22.6 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

28.6 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

28.6 |

28.6 |

27.0 |

25.8 |

25.0 |

24.5 |

24.3 |

24.1 |

24.0 |

23.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

22.9 |

20.6 |

19.7 |

18.9 |

18.2 |

17.7 |

17.5 |

17.4 |

17.2 |

16.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 729 |

|||

22.9 |

22.9 |

22.6 |

22.2 |

22.1 |

22.1 |

22.0 |

21.9 |

21.8 |

21.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welded Pipe and Tube |

||

19.4 |

17.5 |

16.7 |

16.1 |

15.5 |

15.0 |

14.9 |

14.8 |

14.6 |

14.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 464 |

|||

19.4 |

19.4 |

19.2 |

18.8 |

18.8 |

18.8 |

18.7 |

18.6 |

18.5 |

18.5 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|||

19.4 |

17.5 |

16.7 |

16.1 |

15.5 |

15.0 |

14.9 |

14.8 |

14.6 |

14.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 468 |

|||

19.4 |

19.4 |

19.2 |

18.8 |

18.8 |

18.8 |

18.7 |

18.6 |

18.5 |

18.5 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|||

19.8 |

17.7 |

16.3 |

15.4 |

14.6 |

14.1 |

13.9 |

13.8 |

13.6 |

13.5 |

13.4 |

13.3 |

13.3 |

13.2 |

13.1 |

13.1 |

13.0 |

13.0 |

N06617 |

B 546 |

19.8 |

19.8 |

19.8 |

19.8 |

19.8 |

19.1 |

18.8 |

18.6 |

18.4 |

18.3 |

18.1 |

18.0 |

17.9 |

17.8 |

17.8 |

17.7 |

17.6 |

15.4 |

N06617 |

|

24.3 |

22.7 |

20.9 |

19.4 |

18.3 |

17.4 |

17.0 |

16.7 |

16.4 |

16.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

B 619 |

|||

24.3 |

22.7 |

20.9 |

19.4 |

18.3 |

17.4 |

17.0 |

16.7 |

16.4 |

16.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

|

|||

23.2 |

21.2 |

19.6 |

18.1 |

16.9 |

16.0 |

15.5 |

15.1 |

14.8 |

14.5 |

14.4 |

14.2 |

14.1 |

14.0 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

23.2 |

23.2 |

23.2 |

23.2 |

22.9 |

21.4 |

20.9 |

20.4 |

20.0 |

19.6 |

19.4 |

19.2 |

19.0 |

19.0 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

24.3 |

21.8 |

19.6 |

18.1 |

17.1 |

16.4 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.2 |

15.0 |

14.8 |

14.7 |

14.5 |

14.4 |

11.6 |

R30556 |

|

24.3 |

24.3 |

23.8 |

23.0 |

22.5 |

22.1 |

21.7 |

21.4 |

21.1 |

20.9 |

20.7 |

20.5 |

20.2 |

20.0 |

19.8 |

18.0 |

14.4 |

11.6 |

R30556 |

|

24.3 |

24.3 |

23.9 |

23.1 |

22.6 |

22.1 |

21.9 |

21.8 |

21.6 |

21.5 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

B 626 |

|||

24.3 |

24.3 |

23.9 |

23.1 |

22.6 |

22.1 |

21.9 |

21.8 |

21.6 |

21.5 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

|

|||

23.2 |

21.2 |

19.6 |

18.1 |

16.9 |

16.0 |

15.5 |

15.1 |

14.8 |

14.5 |

14.4 |

14.2 |

14.1 |

14.0 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

23.2 |

23.2 |

23.2 |

23.2 |

22.9 |

21.4 |

20.9 |

20.4 |

20.0 |

19.6 |

19.4 |

19.2 |

19.0 |

19.0 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

24.3 |

21.8 |

19.6 |

18.1 |

17.1 |

16.4 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.2 |

15.0 |

14.8 |

14.7 |

14.5 |

14.4 |

11.6 |

R30556 |

|

24.3 |

24.3 |

23.8 |

23.0 |

22.5 |

22.1 |

21.7 |

21.4 |

21.1 |

20.9 |

20.7 |

20.5 |

20.2 |

20.0 |

19.8 |

18.0 |

14.4 |

11.6 |

R30556 |

|

21.1 |

19.7 |

18.1 |

16.8 |

15.6 |

14.7 |

14.4 |

14.4 |

14.4 |

14.4 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

B 673 |

|||

21.1 |

21.1 |

20.4 |

19.5 |

18.8 |

18.2 |

17.9 |

17.7 |

17.4 |

17.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

|

|||

22.9 |

20.5 |

18.3 |

16.7 |

15.9 |

15.3 |

15.0 |

14.9 |

14.8 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

22.9 |

22.9 |

22.3 |

21.1 |

20.1 |

19.4 |

19.0 |

18.7 |

18.4 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

21.1 |

19.7 |

18.1 |

16.8 |

15.6 |

14.7 |

14.4 |

14.4 |

14.4 |

14.4 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

B 674 |

|||

21.1 |

21.1 |

20.4 |

19.5 |

18.8 |

18.2 |

17.9 |

17.7 |

17.4 |

17.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

|

|||

22.9 |

20.5 |

18.3 |

16.7 |

15.9 |

15.3 |

15.0 |

14.9 |

14.8 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

22.9 |

22.9 |

22.3 |

21.1 |

20.1 |

19.4 |

19.0 |

18.7 |

18.4 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

23.1 |

22.2 |

20.2 |

18.7 |

17.4 |

16.5 |

16.1 |

15.8 |

15.5 |

15.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 675 |

|||

23.1 |

23.1 |

21.8 |

20.9 |

20.2 |

19.8 |

19.6 |

19.5 |

19.4 |

19.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

24.3 |

22.2 |

20.2 |

18.7 |

17.4 |

16.5 |

16.1 |

15.8 |

15.5 |

15.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

24.3 |

24.3 |

23.0 |

22.0 |

21.3 |

20.8 |

20.7 |

20.5 |

20.4 |

20.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

23.1 |

22.2 |

20.2 |

18.7 |

17.4 |

16.5 |

16.1 |

15.8 |

15.5 |

15.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 676 |

|||

23.1 |

23.1 |

21.8 |

20.9 |

20.2 |

19.8 |

19.6 |

19.5 |

19.4 |

19.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

24.3 |

22.2 |

20.2 |

18.7 |

17.4 |

16.5 |

16.1 |

15.8 |

15.5 |

15.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

24.3 |

24.3 |

23.0 |

22.0 |

21.3 |

20.8 |

20.7 |

20.5 |

20.4 |

20.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

167 |

--`,,```````,,```,`,`,,,,`,`,`,`-`-`,,`,,`,`,,`--- |

|

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

|

|

|

|

Specified |

Specified |

|

|

UNS |

|

|

|

|

Minimum |

Minimum |

E |

Spec. |

Alloy |

Temper or |

Nominal |

P- |

|

Tensile, |

Yield, |

or |

No. |

No. |

Condition |

Composition |

No. |

Notes |

ksi |

ksi |

F |

|

|

|

|

|

|

|

||

Welded Pipe and Tube (Cont’d) |

|

|

|

|

|

|

||

B 704 |

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(14) |

120 |

60 |

0.85 |

B 705 |

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(14) |

120 |

60 |

0.85 |

B 804 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8) |

95 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8) |

95 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(21) |

100 |

45 |

0.85 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(21) |

100 |

45 |

0.85 |

Plate, Sheet, and Strip |

|

|

|

|

|

|

|

|

B 168 |

N06600 |

Annealed |

Ni–Cr–Fe |

43 |

(1) |

80 |

35 |

1.00 |

|

N06600 |

Annealed |

Ni–Cr–Fe |

43 |

(1)(2) |

80 |

35 |

1.00 |

|

N06600 |

Hot rolled |

Ni–Cr–Fe |

43 |

(1)(4) |

85 |

35 |

1.00 |

|

N06600 |

Hot rolled |

Ni–Cr–Fe |

43 |

(1)(2)(4) |

85 |

35 |

1.00 |

B 168 |

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(7) |

95 |

35 |

1.00 |

|

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(2)(7) |

95 |

35 |

1.00 |

B 409 |

N08800 |

Annealed |

Ni–Cr–Fe |

45 |

(4)(7) |

75 |

30 |

1.00 |

|

N08800 |

Annealed |

Ni–Cr–Fe |

45 |

(2)(4)(7) |

75 |

30 |

1.00 |

|

N08810 |

Annealed |

Ni–Cr–Fe |

45 |

(4)(7) |

65 |

25 |

1.00 |

|

N08810 |

Annealed |

Ni–Cr–Fe |

45 |

(2)(4)(7) |

65 |

25 |

1.00 |

B 424 |

N08825 |

Annealed |

Ni–Fe–Cr–Mo–Cu |

45 |

(1)(7) |

85 |

35 |

1.00 |

|

N08825 |

Annealed |

Ni–Fe–Cr–Mo–Cu |

45 |

(1)(2)(7) |

85 |

35 |

1.00 |

B 435 |

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1) |

100 |

45 |

1.00 |

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2) |

100 |

45 |

1.00 |

B 443 |

N06625 |

Sol. ann. |

Ni–Cr–Mo–Cb |

43 |

(1)(14)(18) |

100 |

40 |

1.00 |

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(14) |

110 |

55 |

1.00 |

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(14)(15) |

120 |

60 |

1.00 |

B 463 |

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

1.00 |

|

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1)(12) |

80 |

35 |

1.00 |

B 575 |

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(12) |

100 |

45 |

1.00 |

|

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(2)(12) |

100 |

45 |

1.00 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12) |

100 |

41 |

1.00 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12) |

100 |

41 |

1.00 |

B 625 |

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1) |

87 |

43 |

1.00 |

|

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1)(2) |

87 |

43 |

1.00 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

45 |

(1)(19)(20) |

94 |

43 |

1.00 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

45 |

(1)(2)(19)(20) |

94 |

43 |

1.00 |

B 688 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(7)(11)(22) |

95 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(7)(11)(22) |

95 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(7)(10)(21) |

100 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(7)(10)(21) |

100 |

45 |

1.00 |

168

--`,,```````,,```,`,`,,,,`,`,`,`-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

---`,,`,,`,`,,`-`-`,,```````,,```,`,`,,,,`,`,`,`--

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

Maximum Allowable Stress Values in Tension, ksi, for Metal Temperature, °F, Not Exceeding |

|

|

|

|

|||||||||||||

−20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNS |

|

to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alloy |

Spec. |

100 |

200 |

300 |

400 |

500 |

600 |

650 |

700 |

750 |

800 |

850 |

900 |

950 |

1,000 |

1,050 |

1,100 |

1,150 |

1,200 |

No. |

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welded Pipe and Tube (Cont’d) |

|||

29.1 |

29.1 |

29.1 |

28.5 |

28.0 |

27.5 |

27.3 |

27.0 |

26.8 |

26.5 |

26.3 |

26.0 |

25.7 |

25.4 |

25.1 |

24.7 |

17.9 |

11.2 |

N06625 |

B 704 |

29.1 |

29.1 |

29.1 |

28.5 |

28.0 |

27.5 |

27.3 |

27.0 |

26.8 |

26.5 |

26.3 |

26.0 |

25.7 |

25.4 |

25.1 |

24.7 |

17.9 |

11.2 |

N06625 |

B 705 |

23.1 |

22.2 |

20.2 |

18.7 |

17.4 |

16.5 |

16.1 |

15.8 |

15.5 |

15.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 804 |

|||

23.1 |

23.1 |

21.8 |

20.9 |

20.2 |

19.8 |

19.6 |

19.5 |

19.4 |

19.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

24.3 |

22.2 |

20.2 |

18.7 |

17.4 |

16.5 |

16.1 |

15.8 |

15.5 |

15.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

24.3 |

24.3 |

23.0 |

22.0 |

21.3 |

20.8 |

20.7 |

20.5 |

20.4 |

20.2 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plate, Sheet, and Strip |

||

22.9 |

21.3 |

20.8 |

20.5 |

20.2 |

19.9 |

19.8 |

19.6 |

19.4 |

19.1 |

18.7 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

B 168 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.9 |

22.4 |

16.0 |

10.6 |

7.0 |

4.5 |

3.0 |

2.2 |

2.0 |

N06600 |

|

23.3 |

22.1 |

21.5 |

21.3 |

21.3 |

21.2 |

21.1 |

21.0 |

20.8 |

20.5 |

20.1 |

19.7 |

19.3 |

14.5 |

10.3 |

7.2 |

5.8 |

5.5 |

N06600 |

|

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

14.5 |

10.3 |

7.2 |

5.8 |

5.5 |

N06600 |

|

23.3 |

20.8 |

19.2 |

18.1 |

17.2 |

16.6 |

16.4 |

16.2 |

16.0 |

15.9 |

15.8 |

15.7 |

15.6 |

15.5 |

15.4 |

15.4 |

15.3 |

15.3 |

N06617 |

B 168 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

22.5 |

22.1 |

21.9 |

21.7 |

21.5 |

21.3 |

21.2 |

21.0 |

20.9 |

20.9 |

20.8 |

20.7 |

18.1 |

N06617 |

|

20.0 |

18.5 |

17.8 |

17.2 |

16.8 |

16.3 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.1 |

14.9 |

14.7 |

14.5 |

13.0 |

9.8 |

6.6 |

N08800 |

B 409 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

19.9 |

17.0 |

13.0 |

9.8 |

6.6 |

N08800 |

|

16.7 |

15.4 |

14.4 |

13.6 |

12.9 |

12.2 |

11.9 |

11.6 |

11.4 |

11.1 |

10.9 |

10.7 |

10.5 |

10.4 |

10.2 |

10.0 |

9.3 |

7.4 |

N08810 |

|

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.5 |

16.1 |

15.7 |

15.3 |

15.0 |

14.7 |

14.5 |

14.2 |

14.0 |

13.8 |

11.6 |

9.3 |

7.4 |

N08810 |

|

23.3 |

21.4 |

20.3 |

19.4 |

18.5 |

17.8 |

17.5 |

17.3 |

17.2 |

17.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08825 |

B 424 |

|||

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.2 |

23.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08825 |

|

|||

28.6 |

25.6 |

23.1 |

21.3 |

20.1 |

19.3 |

18.9 |

18.7 |

18.4 |

18.2 |

18.0 |

17.8 |

17.6 |

17.5 |

17.3 |

17.1 |

16.9 |

13.6 |

R30556 |

B 435 |

28.6 |

28.6 |

28.0 |

27.1 |

26.4 |

26.0 |

25.6 |

25.2 |

24.9 |

24.6 |

24.3 |

24.1 |

23.8 |

23.6 |

23.3 |

21.2 |

17.0 |

13.6 |

R30556 |

|

26.7 |

24.9 |

23.6 |

22.6 |

21.8 |

21.1 |

20.8 |

20.6 |

20.3 |

20.1 |

20.0 |

19.8 |

19.7 |

19.5 |

19.4 |

19.4 |

19.3 |

19.3 |

N06625 |

B 443 |

31.4 |

31.4 |

31.4 |

30.8 |

30.2 |

29.7 |

29.4 |

29.1 |

28.9 |

28.6 |

28.3 |

28.0 |

27.7 |

27.4 |

27.0 |

26.6 |

21.0 |

13.2 |

N06625 |

|

34.3 |

34.3 |

34.3 |

33.6 |

32.9 |

32.4 |

32.1 |

31.8 |

31.5 |

31.2 |

30.9 |

30.6 |

30.3 |

29.9 |

29.5 |

29.0 |

21.0 |

13.2 |

N06625 |

|

22.9 |

20.6 |

19.7 |

18.9 |

18.2 |

17.7 |

17.5 |

17.4 |

17.2 |

16.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 463 |

|||

22.9 |

22.9 |

22.9 |

22.6 |

22.2 |

22.1 |

22.1 |

22.0 |

21.9 |

21.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|||

28.6 |

28.6 |

28.2 |

27.2 |

26.5 |

26.0 |

25.8 |

25.6 |

25.4 |

25.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

B 575 |

|||

28.6 |

28.6 |

28.2 |

27.2 |

26.5 |

26.0 |

25.8 |

25.6 |

25.4 |

25.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

|

|||

27.3 |

24.9 |

23.0 |

21.3 |

19.9 |

18.8 |

18.2 |

17.8 |

17.4 |

17.1 |

16.8 |

16.7 |

16.5 |

16.5 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

27.3 |

27.3 |

27.3 |

27.3 |

26.9 |

25.2 |

24.6 |

24.0 |

23.5 |

23.1 |

22.8 |

22.6 |

22.4 |

22.3 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

24.9 |

23.2 |

21.3 |

19.8 |

18.3 |

17.3 |

17.0 |

16.9 |

16.9 |

16.9 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

B 625 |

|||

24.9 |

24.9 |

23.9 |

23.0 |

22.1 |

21.4 |

21.1 |

20.8 |

20.4 |

20.1 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

|

|||

26.9 |

24.1 |

21.5 |

19.7 |

18.7 |

18.0 |

17.7 |

17.5 |

17.4 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

26.9 |

26.9 |

26.2 |

24.8 |

23.7 |

22.8 |

22.4 |

22.0 |

21.6 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

27.1 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 688 |

|||

27.1 |

27.1 |

25.7 |

24.6 |

23.8 |

23.3 |

23.1 |

22.9 |

22.8 |

22.6 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

28.6 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

28.6 |

28.6 |

27.0 |

25.8 |

25.0 |

24.5 |

24.3 |

24.1 |

24.0 |

23.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

169

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

|

|

|

|

Specified |

Specified |

|

|

UNS |

|

|

|

|

Minimum |

Minimum |

E |

Spec. |

Alloy |

Temper or |

Nominal |

P- |

|

Tensile, |

Yield, |

or |

No. |

No. |

Condition |

Composition |

No. |

Notes |

ksi |

ksi |

F |

|

|

|

|

|

|

|

||

Bars, Rods, Shapes, and Forgings |

|

|

|

|

|

|

||

B 166 |

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(7) |

95 |

35 |

1.00 |

|

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(2)(7) |

95 |

35 |

1.00 |

B 408 |

N08800 |

Annealed |

Ni–Cr–Fe |

45 |

(7) |

75 |

30 |

1.00 |

|

N08800 |

Annealed |

Ni–Cr–Fe |

45 |

(2)(7) |

75 |

30 |

1.00 |

|

N08810 |

Annealed |

Ni–Cr–Fe |

45 |

(7) |

65 |

25 |

1.00 |

|

N08810 |

Annealed |

Ni–Cr–Fe |

45 |

(2)(7) |

65 |

25 |

1.00 |

B 425 |

N08825 |

Annealed |

Ni–Fe–Cr–Mo–Cu |

45 |

(1)(7) |

85 |

35 |

1.00 |

|

N08825 |

Annealed |

Ni–Fe–Cr–Mo–Cu |

45 |

(1)(2)(7) |

85 |

35 |

1.00 |

B 446 |

N06625 |

Sol. ann. |

Ni–Cr–Mo–Cb |

43 |

(1)(14)(18) |

100 |

40 |

1.00 |

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(2)(14)(16) |

110 |

50 |

1.00 |

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(2)(14)(15)(17) |

120 |

60 |

1.00 |

B 462 |

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

1.00 |

|

N08020 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

1.00 |

B 473 |

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

1.00 |

|

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

1.00 |

B 564 |

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(7) |

95 |

35 |

1.00 |

|

N06617 |

Annealed |

52Ni–22Cr–13Co–9Mo |

43 |

(1)(2)(7) |

95 |

35 |

1.00 |

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(2)(14)(16) |

110 |

50 |

1.00 |

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(2)(14)(15)(17) |

120 |

60 |

1.00 |

B 564 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(22) |

95 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

1.00 |

|

N08800 |

Annealed |

Ni–Cr–Fe |

45 |

(1) |

75 |

30 |

1.00 |

|

N08800 |

Annealed |

Ni–Cr–Fe |

45 |

(1)(2) |

75 |

30 |

1.00 |

|

N08810 |

Annealed |

Ni–Cr–Fe |

45 |

(1) |

65 |

25 |

1.00 |

|

N08810 |

Annealed |

Ni–Cr–Fe |

45 |

(1)(2) |

65 |

25 |

1.00 |

B 572 |

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1) |

100 |

45 |

1.00 |

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2) |

100 |

45 |

1.00 |

B 574 |

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(12) |

100 |

45 |

1.00 |

|

N06022 |

Sol. ann. |

Ni–Mo–Cr–Low C |

44 |

(1)(2)(12) |

100 |

45 |

1.00 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12) |

100 |

41 |

1.00 |

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12) |

100 |

41 |

1.00 |

B 649 |

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1) |

87 |

43 |

1.00 |

|

N08925 |

Annealed |

Ni–Fe–Cr–Mo–Cu–Low C |

45 |

(1)(2) |

87 |

43 |

1.00 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

. . . |

(1) |

94 |

43 |

1.00 |

|

N08926 |

Annealed |

Ni–Fe–Cr–Mo–Cu–N–Low C |

. . . |

(1)(2) |

94 |

43 |

1.00 |

B 691 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(8)(22) |

95 |

45 |

1.00 |

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–Cu–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

1.00 |

170

--`,,```````,,```,`,`,,,,`,`,`,`-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

Maximum Allowable Stress Values in Tension, ksi, for Metal Temperature, °F, Not Exceeding |

|

|

|

||||||||||||||

−20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNS |

|

to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alloy |

Spec. |

100 |

200 |

300 |

400 |

500 |

600 |

650 |

700 |

750 |

800 |

850 |

900 |

950 |

1,000 |

1,050 |

1,100 |

1,150 |

1,200 |

No. |

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bars, Rods, Shapes, and Forgings |

|||

23.3 |

20.8 |

19.2 |

18.1 |

17.2 |

16.6 |

16.4 |

16.2 |

16.0 |

15.9 |

15.8 |

15.7 |

15.6 |

15.5 |

15.4 |

15.4 |

15.3 |

15.3 |

N06617 |

B 166 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

22.5 |

22.1 |

21.9 |

21.7 |

21.5 |

21.3 |

21.2 |

21.0 |

20.9 |

20.9 |

20.8 |

20.7 |

18.1 |

N06617 |

|

20.0 |

18.5 |

17.8 |

17.2 |

16.8 |

16.3 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.1 |

14.9 |

14.7 |

14.5 |

13.0 |

9.8 |

6.6 |

N08800 |

B 408 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

19.9 |

17.0 |

13.0 |

9.8 |

6.6 |

N08800 |

|

16.7 |

15.4 |

14.4 |

13.6 |

12.9 |

12.2 |

11.9 |

11.6 |

11.4 |

11.1 |

10.9 |

10.7 |

10.5 |

10.4 |

10.2 |

10.0 |

9.3 |

7.4 |

N08810 |

|

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.5 |

16.1 |

15.7 |

15.3 |

15.0 |

14.7 |

14.5 |

14.2 |

14.0 |

13.8 |

11.6 |

9.3 |

7.4 |

N08810 |

|

23.3 |

21.4 |

20.3 |

19.4 |

18.5 |

17.8 |

17.5 |

17.3 |

17.2 |

17.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08825 |

B 425 |

|||

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

23.2 |

23.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08825 |

|

|||

26.7 |

24.9 |

23.6 |

22.6 |

21.8 |

21.1 |

20.8 |

20.6 |

20.3 |

20.1 |

20.0 |

19.8 |

19.7 |

19.5 |

19.4 |

19.4 |

19.3 |

19.3 |

N06625 |

B 446 |

31.4 |

31.4 |

31.4 |

30.8 |

30.2 |

29.7 |

29.4 |

29.1 |

28.9 |

28.6 |

28.3 |

28.0 |

27.7 |

27.4 |

27.0 |

26.6 |

21.0 |

13.2 |

N06625 |

|

34.3 |

34.3 |

34.3 |

33.6 |

32.9 |

32.4 |

32.1 |

31.8 |

31.5 |

31.2 |

30.9 |

30.6 |

30.3 |

29.9 |

29.5 |

29.0 |

21.0 |

13.2 |

N06625 |

|

22.9 |

20.6 |

19.7 |

18.9 |

18.2 |

17.7 |

17.5 |

17.4 |

17.2 |

16.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 462 |

|||

22.9 |

22.9 |

22.6 |

22.2 |

22.1 |

22.1 |

22.0 |

21.9 |

21.8 |

21.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|||

22.9 |

20.6 |

19.7 |

18.9 |

18.2 |

17.7 |

17.5 |

17.4 |

17.2 |

16.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 473 |

|||

22.9 |

22.9 |

22.6 |

22.2 |

22.1 |

22.1 |

22.0 |

21.9 |

21.8 |

21.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|||

23.3 |

20.8 |

19.2 |

18.1 |

17.2 |

16.6 |

16.4 |

16.2 |

16.0 |

15.9 |

15.8 |

15.7 |

15.6 |

15.5 |

15.4 |

15.4 |

15.3 |

15.3 |

N06617 |

B 564 |

23.3 |

23.3 |

23.3 |

23.3 |

23.3 |

22.5 |

22.1 |

21.9 |

21.7 |

21.5 |

21.3 |

21.2 |

21.0 |

20.9 |

20.9 |

20.8 |

20.7 |

18.1 |

N06617 |

|

31.4 |

31.4 |

31.4 |

30.8 |

30.2 |

29.7 |

29.4 |

29.1 |

28.9 |

28.6 |

28.3 |

28.0 |

27.7 |

27.4 |

27.0 |

26.6 |

21.0 |

13.2 |

N06625 |

|

34.3 |

34.3 |

34.3 |

33.6 |

32.9 |

32.4 |

32.1 |

31.8 |

31.5 |

31.2 |

30.9 |

30.6 |

30.3 |

29.9 |

29.5 |

29.0 |

21.0 |

13.2 |

N06625 |

|

27.1 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 564 |

|||

27.1 |

27.1 |

25.7 |

24.6 |

23.8 |

23.3 |

23.1 |

22.9 |

22.8 |

22.6 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

20.0 |

18.5 |

17.8 |

17.2 |

16.8 |

16.3 |

16.1 |

15.9 |

15.7 |

15.5 |

15.3 |

15.1 |

14.9 |

14.7 |

14.5 |

13.0 |

9.8 |

6.6 |

N08800 |

|

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

19.9 |

17.0 |

13.0 |

9.8 |

6.6 |

N08800 |

|

16.7 |

15.4 |

14.4 |

13.6 |

12.9 |

12.2 |

11.9 |

11.6 |

11.4 |

11.1 |

10.9 |

10.7 |

10.5 |

10.4 |

10.2 |

10.0 |

9.3 |

7.4 |

N08810 |

|

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.5 |

16.1 |

15.7 |

15.3 |

15.0 |

14.7 |

14.5 |

14.2 |

14.0 |

13.8 |

11.6 |

9.3 |

7.4 |

N08810 |

|

28.6 |

25.6 |

23.1 |

21.3 |

20.1 |

19.3 |

18.9 |

18.7 |

18.4 |

18.2 |

18.0 |

17.8 |

17.6 |

17.5 |

17.3 |

17.1 |

16.9 |

13.6 |

R30556 |

B 572 |

28.6 |

28.6 |

28.0 |

27.1 |

26.4 |

26.0 |

25.6 |

25.2 |

24.9 |

24.6 |

24.3 |

24.1 |

23.8 |

23.6 |

23.3 |

21.2 |

17.0 |

13.6 |

R30556 |

|

28.6 |

22.9 |

22.9 |

22.6 |

22.2 |

22.1 |

22.1 |

22.0 |

21.9 |

21.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

B 574 |

|||

28.6 |

28.6 |

28.2 |

27.2 |

26.5 |

26.0 |

25.8 |

25.6 |

25.4 |

25.3 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

|

|||

27.3 |

24.9 |

23.0 |

21.3 |

19.9 |

18.8 |

18.2 |

17.8 |

17.4 |

17.1 |

16.9 |

16.7 |

16.6 |

16.5 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

27.3 |

27.3 |

27.3 |

27.3 |

26.9 |

25.2 |

24.6 |

24.0 |

23.5 |

23.1 |

22.8 |

22.6 |

22.4 |

22.3 |

. . . |

. . . |

. . . |

. . . |

N10276 |

|

24.9 |

23.2 |

21.3 |

19.8 |

18.3 |

17.3 |

17.0 |

16.9 |

16.9 |

16.9 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

B 649 |

|||

24.9 |

24.9 |

23.9 |

23.0 |

22.1 |

21.4 |

21.1 |

20.8 |

20.4 |

20.1 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08925 |

|

|||

26.9 |

24.1 |

21.5 |

19.7 |

18.7 |

18.0 |

17.7 |

17.5 |

17.4 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

26.9 |

26.9 |

26.2 |

24.8 |

23.7 |

22.8 |

22.4 |

22.0 |

21.6 . . . . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08926 |

|

||||

27.1 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

B 691 |

|||

27.1 |

27.1 |

25.7 |

24.6 |

23.8 |

23.3 |

23.1 |

22.9 |

22.8 |

22.6 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|||

171

Copyright ASME International--`,,```````,,```,`,`,,

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

|

|

|

|

|

|

Specified |

Specified |

|

|

|

|

UNS |

|

|

|

|

Minimum |

Minimum |

E |

|

|

Spec. |

Alloy |

Temper or |

Nominal |

P- |

|

Tensile, |

Yield, |

or |

|

|

No. |

No. |

Condition |

Composition |

No. |

Notes |

ksi |

ksi |

F |

|

|

|

|

|

|

|

|

|

|

|

|

Seamless Fittings |

|

|

|

|

|

|

|

||

(10) |

B 366 |

N06022 |

Sol. ann. |

Low C–Ni–Mo–Cr |

44 |

(1)(12) |

100 |

45 |

1.00 |

|

(10) |

|

|

N06022 |

Sol. ann. |

Low C–Ni–Mo–Cr |

44 |

(1)(2)(12) |

100 |

45 |

1.00 |

(10) |

|

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(14) |

110 |

50 |

1.00 |

|

B 366 |

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

. . . |

|

|

|

|

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

. . . |

(10) |

|

|

N08367 |

Annealed |

Fe–Ni–Cr–Mo–N |

45 |

(1)(8)(22) |

95 |

45 |

1.00 |

(10) |

|

|

N08367 |

Annealed |

Fe–Ni–Cr–Mo–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

1.00 |

(10) |

B 366 |

N08925 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu |

45 |

(1) |

87 |

43 |

1.00 |

|

(10) |

|

|

N08925 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu |

45 |

(1)(2) |

87 |

43 |

1.00 |

(10) |

|

|

N08926 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu–N |

45 |

(1) |

94 |

43 |

1.00 |

(10) |

|

|

N08926 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu–N |

45 |

(1)(2) |

94 |

43 |

1.00 |

|

B 366 |

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12) |

100 |

41 |

1.00 |

|

|

|

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12) |

100 |

41 |

1.00 |

|

|

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1) |

100 |

45 |

1.00 |

|

|

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2) |

100 |

45 |

1.00 |

(10) |

B 462 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–N |

45 |

(1)(8)(22) |

95 |

45 |

1.00 |

|

(10) |

|

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

1.00 |

|

Welded Fittings |

|

|

|

|

|

|

|

||

(10) |

B 366 |

N06022 |

Sol. ann. |

Low C–Ni–Mo–Cr |

44 |

(1)(12) |

100 |

45 |

0.85 |

|

(10) |

|

|

N06022 |

Sol. ann. |

Low C–Ni–Mo–Cr |

44 |

(1)(12)(13) |

100 |

45 |

1.00 |

(10) |

|

|

N06022 |

Sol. ann. |

Low C–Ni–Mo–Cr |

44 |

(1)(2)(12) |

100 |

45 |

0.85 |

(10) |

|

|

N06022 |

Sol. ann. |

Low C–Ni–Mo–Cr |

44 |

(1)(2)(12)(13) |

100 |

45 |

1.00 |

(10) |

|

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(14) |

110 |

50 |

0.85 |

(10) |

|

|

N06625 |

Annealed |

Ni–Cr–Mo–Cb |

43 |

(1)(13)(14) |

110 |

50 |

1.00 |

(10) |

B366 |

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1) |

80 |

35 |

0.85 |

|

(10) |

|

|

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1)(13) |

80 |

35 |

1.00 |

(10) |

|

|

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1)(2) |

80 |

35 |

0.85 |

(10) |

|

|

N08020 |

Annealed |

Cr–Ni–Fe–Mo–Cu–Cb |

45 |

(1)(2)(13) |

80 |

35 |

1.00 |

(10) |

B 366 |

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–N |

45 |

(1)(8)(22) |

95 |

45 |

0.85 |

|

(10) |

|

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–N |

45 |

(1)(8)(13)(22) |

95 |

45 |

1.00 |

(10) |

|

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–N |

45 |

(1)(2)(8)(22) |

95 |

45 |

0.85 |

(10) |

|

|

N08367 |

Sol. ann. |

Fe–Ni–Cr–Mo–N |

45 |

(1)(2)(8)(13)(22) |

95 |

45 |

1.00 |

(10) |

B 366 |

N08925 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu |

45 |

(1) |

87 |

43 |

0.85 |

|

(10) |

|

|

N08925 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu |

45 |

(1)(13) |

87 |

43 |

1.00 |

(10) |

|

|

N08925 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu |

45 |

(1)(2) |

87 |

43 |

0.85 |

(10) |

|

|

N08925 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu |

45 |

(1)(2)(13) |

87 |

43 |

1.00 |

(10) |

B 366 |

N08926 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu–N |

45 |

(1)(19)(20) |

94 |

43 |

0.85 |

|

(10) |

|

|

N08926 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu–N |

45 |

(1)(13) |

94 |

43 |

1.00 |

(10) |

|

|

N08926 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu–N |

45 |

(1)(2)(19)(20) |

94 |

43 |

0.85 |

(10) |

|

|

N08926 |

Annealed |

Low C–Ni–Fe–Cr–Mo–Cu–N |

45 |

(1)(2)(13) |

94 |

43 |

1.00 |

|

B 366 |

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12) |

100 |

41 |

0.85 |

|

(10) |

|

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(12)(13) |

100 |

41 |

1.00 |

|

|

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12) |

100 |

41 |

0.85 |

(10) |

|

|

N10276 |

Sol. ann. |

Low C–Ni–Mo–Cr |

43 |

(1)(2)(12)(13) |

100 |

41 |

1.00 |

|

B 366 |

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(12) |

100 |

45 |

0.85 |

|

(10) |

|

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(13) |

100 |

45 |

1.00 |

|

|

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2)(12) |

100 |

45 |

0.85 |

(10) |

|

|

R30556 |

Annealed |

Ni–Fe–Cr–Co–Mo–W |

45 |

(1)(2)(13) |

100 |

45 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

172

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

--`,,```````,,```,`,`,,,,`,`,`,`-`-`,,`,,`,`,,`---

ASME B31.1-2010

Table A-4 Nickel and High Nickel Alloys (Cont’d)

|

|

Maximum Allowable Stress Values in Tension, ksi, for Metal Temperature, °F, Not Exceeding |

|

|

|

|

|

|

|||||||||||||

−20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNS |

|

|

|

to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alloy |

Spec. |

|

|

100 |

200 |

300 |

400 |

500 |

600 |

650 |

700 |

750 |

800 |

850 |

900 |

950 |

1,000 |

1,050 |

1,100 |

1,150 |

1,200 |

No. |

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seamless Fittings |

|

||

28.6 |

26.7 |

24.6 |

22.9 |

21.5 |

20.4 |

20.0 |

19.6 |

19.3 |

19.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

B 366 |

(10) |

||||

28.6 |

28.6 |

28.2 |

27.2 |

26.5 |

26.0 |

25.8 |

25.6 |

25.4 |

25.3 |

|

. . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N06022 |

|

|

(10) |

|

31.4 |

31.4 |

31.4 |

30.8 |

30.2 |

29.7 |

29.4 |

29.1 |

28.9 |

28.6 |

28.3 |

28.0 |

27.7 |

27.4 |

27.0 |

26.6 |

21.0 |

13.2 |

N06625 |

|

|

(10) |

22.9 |

20.6 |

19.7 |

18.9 |

18.2 |

17.7 |

17.5 |

17.4 |

17.2 |

16.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

B 366 |

|

||||

22.9 |

22.9 |

22.6 |

22.2 |

22.1 |

22.1 |

22.0 |

21.9 |

21.8 |

21.8 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08020 |

|

|

|

|||

27.1 |

26.2 |

23.8 |

21.9 |

20.5 |

19.4 |

19.0 |

18.6 |

18.3 |

18.0 . . . . . . . . . |

. . . |

. . . |

. . . |

. . . |

. . . |

N08367 |

|

|

(10) |

|||

27.1 |

27.1 |

25.7 |

24.6 |

23.8 |

23.3 |

23.1 |