- •5.3 Test Instructions

- •Table of Allowable Rapid Fluctuations of Certain Key Measurements.

- •5.5.6 Data Verification

- •5.6 Results

- •5.7 Analysis

- •5.7.1 Method of Trending Results

- •5.8 Report

- •HP / IP Turbine Efficiency Test

- •Typical Control Room Data Sheet

- •Point ID

- •Condenser

- •Annexure - I

- •CONDENSER DESIGN DATA

- •Annexure - II

- •TEST READINGS

- •Annexure - III

- •TYPICAL CONTROL ROOM READINGS

- •UNITS

- •kcal/hr

- •3.0 Working And Test Set Up

- •TEST ENGINEER (TE):-----------------------------------------

- •ENGINEERING REVIEW

- •PERSONNEL REQUIRED

- •TEST CREW ORIENTATION

- •REFERENCE DRAWINGS

- •LEAK DETECTOR OPERATION

- •TEST LOG

- •ACCESSIBILITY

- •CONTROL ROOM / UNIT DATA

- •LIST OF INSTRUMENTS & ACCESSORIES REQUIRED FOR AIR-IN-LEAK TEST

- •L. P. Turbine

- •*Total time from leak sensing by instrument to retrieval to zero (0)

- •Unit

- •LOW FEED WATER TEMPERATURE

- •EXCESSIVE MAKEUP

- •HIGH WATER LEVEL

- •EXCESSIVE NUMBER OF TUBES PLUGGED

- •HIGH DRAIN COOLER APPROACH TEMPERATURE (DCA)

- •DRAIN COOLER INLET NOT SUBMERGED

- •IMPROPER SETTING

- •EXCESSIVE TUBE BUNDLE PRESSURE DROP

- •HP Heater Test Data

- •Control Room Readings

- •FAULT TREE

- •LP Heater Test Data

- •Control Room Readings

- •FAULT TREE

- •LOW FEED WATER TEMPERATURE

- •EXCESSIVE MAKEUP

- •WORN VENT

- •HIGH WATER LEVEL

- •TUBE LEAKES

- •HEADER PARTITION LEAKS

- •EXCESSIVE NUMBER OF TUBES PLUGGED

- •HIGH DRAIN COOLER APPROACH TEMPERATURE (DCA)

- •DRAIN COOLER INLET NOT SUBMERGED

- •IMPROPER SETTING

- •EXCESSIVE TUBE BUNDLE PRESSURE DROP

- •EXCESSIVE NUMBER OF TUBES PLUGGED

- •Unit

- •BFP Test Data

- •Typical Control Room Readings

- •Boiler Feed Pump A / B / C

- •Typical DAS Readings

- •Description

- •CONTENTS

- •1.0 Introduction

- •3.1 Process Description

- •4 References

- •4.1 ASME Performance Test Code 4.2 – 1969, Coal Pulverizers

- •5 Prerequisites

- •(A clean air test is performed with the primary air to the mill at full load normal conditions with the mill out of service (normal primary airflow, no fuel flow)).

- •Avg. Velocity

- •6.4 Isokinetic Coal Sampling

- •4.5.2 Unburned in Flyash at Economizer Outlet

- •Summary

- •Dry Gas Loss

- •Gas Temp Leaving AH - Corr. to Design Ambient

- •OBJECTIVE : Determine the amount of Power being consumed by the primary plant equipment.

- •TEST ENGINEER (TE):

- •REFERENCE: ASME PTC 19.6-1955 and TVA Proc. No. TS/PERF/RTST/FOS/16.0

- •BILL OF MATERIALS

- •BILL OF MATERIALS

- •Note: Quantities to be decided as per the requirement

- •2.4 PORTABLE DATA ACQUISITION SYSTEM

- •BILL OF MATERIAL

- •Acquisition

- •EQUIPMENT: Thermocouple wire for flue gas temperature measurement

- •2.9 HIGH VELOCITY THERMOCOUPLE (HVT) PROBE

- •2.11 HIGH VOLUME FLYASH SAMPLER

BILL OF MATERIALS

(A)PRESSURE / DIFFERENTIAL TRANSMITTERS :

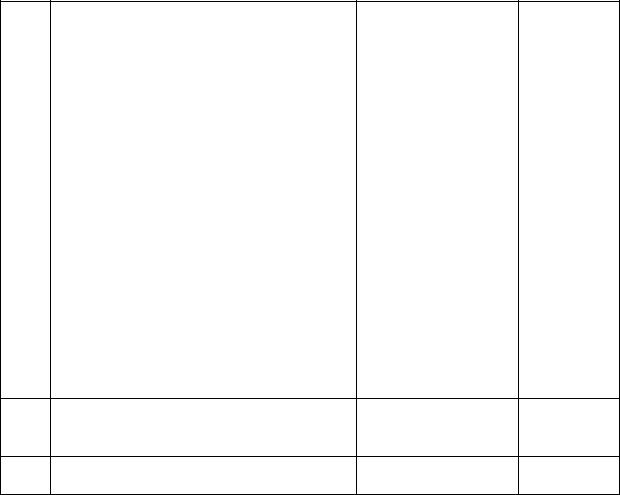

Sl.No. |

Range |

Type |

1. |

0-250 kg/cm2 |

Gauge |

2. |

0-60 kg/cm2 |

Gauge |

3. |

0-25 kg/cm2 |

Gauge |

4. |

0-2 kg/cm2 |

Absolute |

5. |

0-0.35 kg/cm2 |

Absolute (Vacuum Service) |

6. |

0-1 kg/cm2 |

Differential Press. (High Static Press.) |

7. |

0-2.5 kg/cm2 |

Differential Press. (High Static Press.) |

(B)ACCESSORIES FOR EACH TRANSMITTER :

|

|

Pr.Trans. |

Diff.Pr.Trans. |

|

1. |

Manifolds, one for each transmitter |

1 No. |

1 |

No. |

2. |

Lead cables as per spec |

1 No. |

1 |

No. |

3. |

Capillaries |

1 No. |

2 |

Nos. |

4. |

Compression fittings (¼ inch) |

1 No. |

|

2 Nos. |

5. |

Compression fittings (1/2 inch) |

1 No. |

2 |

Nos. |

(C)COMMON SERVICE ITEMS :

1.Hand held communicator

2.Shielded extension cable 20 meters

3.Shielded extension cable 50 meters.

Section: 2.1 Page 7/6

2.2 DIFFERENTIAL PRESSURE TRANSMITTER RANGE 0 TO 2.5 kg/cm2 (HIGH STATIC PRESSURE)

1)Smart microprocessor based, analog output, pressure transmitter with digital communication capability shall be furnished with suitable three valve manifolds.

2)Pressure transmitter shall be constructed to withstand:

A)Working pressure between 20 mm Hg to 200 kg/cm2.

B)Static pressure effect: 0.1 % of URL / 65 kg/cm2 up to 125 kg/cm2

0.2% of URL/65 kg/cm2above 125 kg/cm2

3)The transmitter shall be of two-wire type with an output signal range 4 to 20 mA DC and shall be based on state of the art, field proven technology. The transmitter shall be microprocessor based with digital communication capability and with local LCD indication for output.

4)The electronic transmitter shall meet or exceed the following requirements. PERFORMANCE SPECIFICATIONS:

A)Accuracy: +/-0.075% of span or better including hysterisis, linearity and repeatability of pressure sensor for span from 1:1 to 10:1 of URL.

B)It shall have 12-point calibration. The calibration shall be as per BS6447 (or equivalent), calibration data is to be supplied for each transmitter. (six rising points and six falling points)

C)Stability: +/-0.1% of URL for 6 months.

D)Operating temp range:

i)for sensor – 0 to 85oC.

ii)for electronics and housing – 0 to 80oC.

E) |

Temp variation effect: max. Of 0.015% per 3o C with respect to the |

|

calibration temperature |

F)Power supply range: 12V to 45V DC.

G)Humidity Range: 0 to 95 %

5)Transmitters shall be able to drive output impedance of 500 Ω minimum.

6)Transmitters shall be provided with test point connection and output terminals physically separated from other electronics so that transmitter electronics as not exposed during testing and terminations.

7)Transmitter measuring element assembly shall have SS316 diaphragms, stainless steel body and high tensile carbon steel bolts.

Section: 2.2 Page 1/6

8)Transmitters shall be provided with suitable drain and vent points for the measuring element.

9)Transmitters shall be provided with IP-55 dust tight and weather proof housing with durable corrosion resistant coating.

10)All connections for electric wiring shall be provided with threaded holes or knockouts for electrical conduit connections not smaller than ½ inch nominal size.

11)Accessories : a) each transmitter shall be provided with manifolds as per the following specification :

1)type: two valve (three valve)

2)material: SS 316

3)inlet/ outlet :1/2 inch NPT(F)

4)test and drain connections: ¼ inch NPT(F) with drain plug.

5)body and bonnet: SS 316

6)gland packing of ptfe/abs rings suitable for the pressure and temp. Rating of 400kg/cm2 at 260oC.

7)the process connection to the transmitters shall be through swagelok type compression fittings both at the transmitter end and the process end. The compression fittings shall be suitable for S.S. capillary specified below.

B)1) S.S. capillary for connecting the process pipe to the transmitter inlet port. Capillary

size: 3 mm O.D. & 1 MM I.D. length –1.5 meters.

2)compression fittings for the capillary connections on the transmitter end & the processor end.

3)the fittings should be of ‘swagelok’ type S.S. compression fitting with ½ inch & ¼ inch male thread connection for process end & transmitter end respectively and compression end size suitable for 3mm capillary.

C)Each transmitter shall be provided with a two meter long shielded signal

cable (Beldon E-88761-E-108998 series or equivalent) of minimum 16 AWG conductor size and suitable for 200o temp. The cable shall have teflon insulation for individual cores and overall teflon insulation. This signal cable shall be provided with suitable lugs for screwed terminations at both ends (transmitter and D.A.S I/O termination unit). Also suitable gland for connections at transmitter end are to be provided with signal cables.

12)Transmitter shall be equipped with all accessories for specified service conditions.

Note: Other differential pressure transmitters (different ranges) to have same specification.

Technical Data Sheet: Differential Pressure Transmitter: Range 0 to 2.5 Kg/cm2

Section: 2.2 Page 2/6

The following data shall be furnished for the equipment model quoted.

Sl.No. |

NTPC Requirements |

|

Vendor Compliance |

Remarks / |

|

|

|

|

|

|

Deviations |

1. |

Manufacturer’s Name |

|

|

|

|

2. |

Model No. |

|

|

|

|

3. |

Ordering Code |

|

|

|

|

4. |

Smart range Pressure transmitter with |

|

|

||

|

microprocessor, analog output with digital |

|

|

||

|

communication capability with suitable three |

|

|

||

|

valve manifolds |

|

|

|

|

5. |

Working pressure between 20 mm Hg to 200 |

|

|

||

|

kg/cm2 |

|

|

|

|

|

Static pressure effect : |

|

|

|

|

|

|

0.1%of URL/65 kg/cm2 |

up to |

|

|

|

|

125 Kg/cm2 |

|

|

|

|

|

0.2 % of URL/65 kg/cm 2 |

|

|

|

|

|

above 125 kg/cm2 |

|

|

|

6. |

a) |

Two wire type with an output signal range |

|

|

|

|

|

4 – 20 m A DC with state of art and field |

|

|

|

|

|

proven technology. |

|

|

|

|

b) |

Microprocessor based with digital |

|

|

|

|

|

communication capability and with local |

|

|

|

|

|

LCD indication for output |

|

|

|

7. |

Performance Specifications: |

|

|

|

|

|

a) |

Accuracy: + / - 0.075% of span or better |

|

|

|

|

|

Including hysteresis, linearity, and |

|

|

|

|

|

Repeatability of pressure sensor for span |

|

|

|

|

|

From 1:1 to 10:1 of URL |

|

|

|

|

b) 12 point calibration data sheet as per |

|

|

||

|

|

BS 6447 (or equivalent) to be supplied |

|

|

|

|

|

for each transmitter. (six rising and six |

|

|

|

|

|

falling) |

|

|

|

|

c) Stability: + / - 0.1% of URL for 6 months |

|

|

||

|

d) |

Operating temperature range: |

|

|

|

|

|

(i) for sensor – 0 to 85o C |

|

|

|

|

|

(ii)for electronics and housing – 0 to 80oC |

|

|

|

|

e) Temp. variation effect: Max. of 0.015% |

|

|

||

|

|

per 3 deg. C with respect to the calibration |

|

|

|

|

|

temperature. |

|

|

|

|

f) Power Supply Range: 12V to 45V DC |

|

|

||

|

|

Humidity range to 95%` |

|

|

|

|

|

|

|

||

Sl.No. |

NTPC Requirements |

|

Vendor Compliance |

Remarks / |

|

|

|

|

|

|

Deviations |

Section: 2.2 Page 3/6

8. |

Output impedance of 500 Ohms minimum |

|

|

|

|

|

|

|

|

9. |

Test point connection and output terminals |

|

|

|

|

physically separated from other electronics |

|

|

|

|

so that transmitter electronics is not exposed |

|

|

|

|

during testing and terminations |

|

|

|

10. |

Element measurement assembly shall have |

|

|

|

|

SS 316 diaphragms, stainless steel body and |

|

|

|

|

high tensile carbon steel bolts |

|

|

|

|

|

|

|

|

11. |

Suitable drain and vent points for measuring |

|

|

|

|

element |

|

|

|

|

|

|

|

|

12. |

IP 55 dust tight and weather proof housing |

|

|

|

|

with durable corrosion resistant coating |

|

|

|

|

|

|

|

|

. |

|

|

|

|

13. |

Connections for electric wiring with threaded |

|

|

|

|

holes or knock outs for electrical conduct |

|

|

|

|

connections not smaller than ½ inch nominal |

|

|

|

|

size |

|

|

|

|

|

|

|

|

14. |

a) |

Accessories: Manifolds as per the |

|

|

|

|

following specifications: |

|

|

|

i) |

Type : Three valve |

|

|

|

ii) |

Material : SS 316 |

|

|

|

iii) Inlet/Outlet: ½ inch NPT(F) |

|

|

|

|

iv) |

Test and drain connections: ¼ inch |

|

|

|

|

NPT(F) with plug |

|

|

|

v) Body and bonnet: SS 316 |

|

|

|

|

vi) Gland packing of PTFE/ABS rings |

|

|

|

|

|

suitable for the pressure and temperature |

|

|

|

|

rating of 400 kg/cm2 at 260o C |

|

|

|

b) |

|

|

|

|

i) |

SS Capillary for connecting the process |

|

|

|

|

pipe to the transmitter inlet port. |

|

|

|

|

Capillary size: 3 mm O.D & 1 mm I.D |

|

|

Section: 2.2 Page 4/6

Length – 1.5 meters

ii)Compression fittings for the capillary connections on the transmitter end and the process end.

iii)The fittings should be ‘Swagelok’ type S.S compression fitting with ½ inch and ¼ inch male thread connection for process end and transmitter end respectively

c) To be provided with three meter long shielded signal cable (Beldon E-88761-E- 108998 series or equivalent) of minimum 16 AWG conductor size and suitable for 200o C temperature and overall teflon insulation. Signal cable shall be provided with suitable lugs for screwed terminations at both ends.

15.Equipped with all accessories for specified service conditions

16.Documents: Operation & Maintenance manual ( 2 sets)

Notes:

A)Data sheets to be submitted along with the offer clearly indicating deviations, if any.

B)Detailed Quality Plan & Type test report after ordering to be submitted for approval

C)Test & Guarantee Certificate to be submitted before the dispatch clearance

Maintenance: After sales maintenance support to be available in India through authorized representative or directly.

Section: 2.2 Page 5/6