Пинч / Kemper%20IOMSA%202009%20KC

.pdf

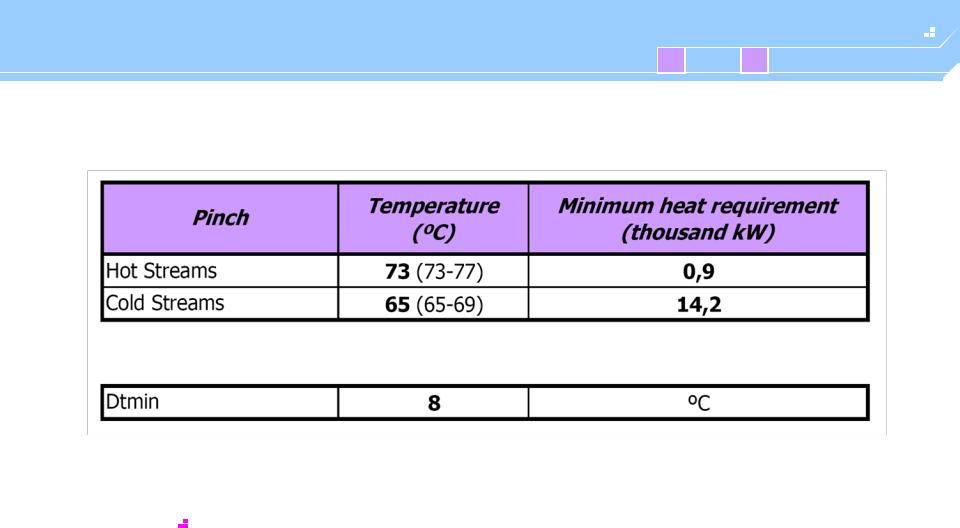

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

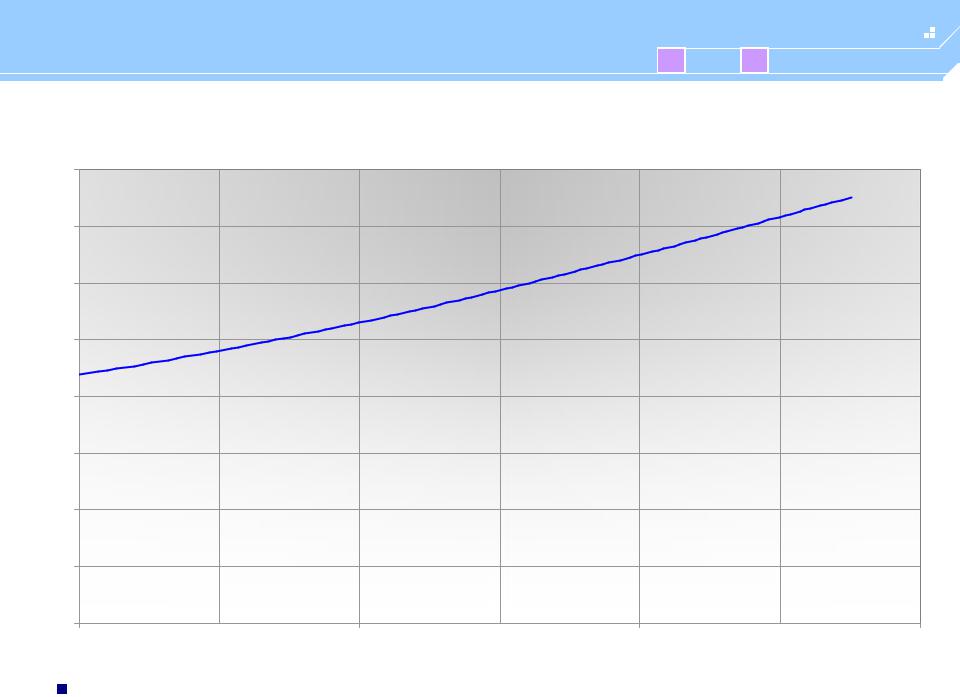

Figures from the Hot and Cold Composite Curves.

Figures from the Hot and Cold Composite Curves.

Reminder:

Do not use cooling water above 73 ºC (163 ºF)

Do not use heating steam below 69 ºC (156 ºF)

Pinch Analysis - Case I

Pinch Analysis - Case I

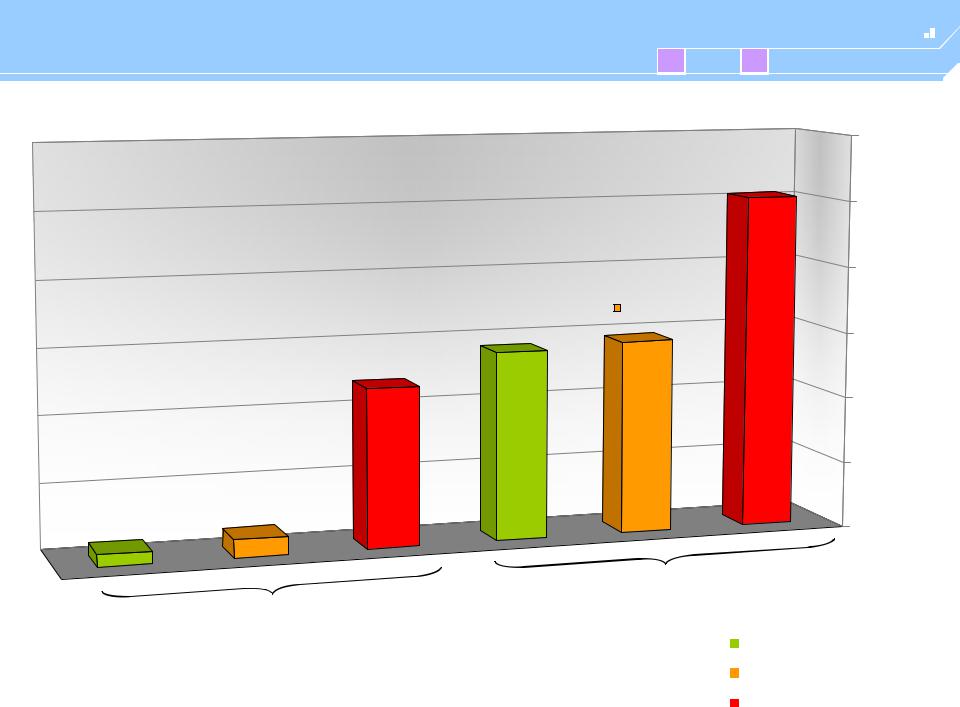

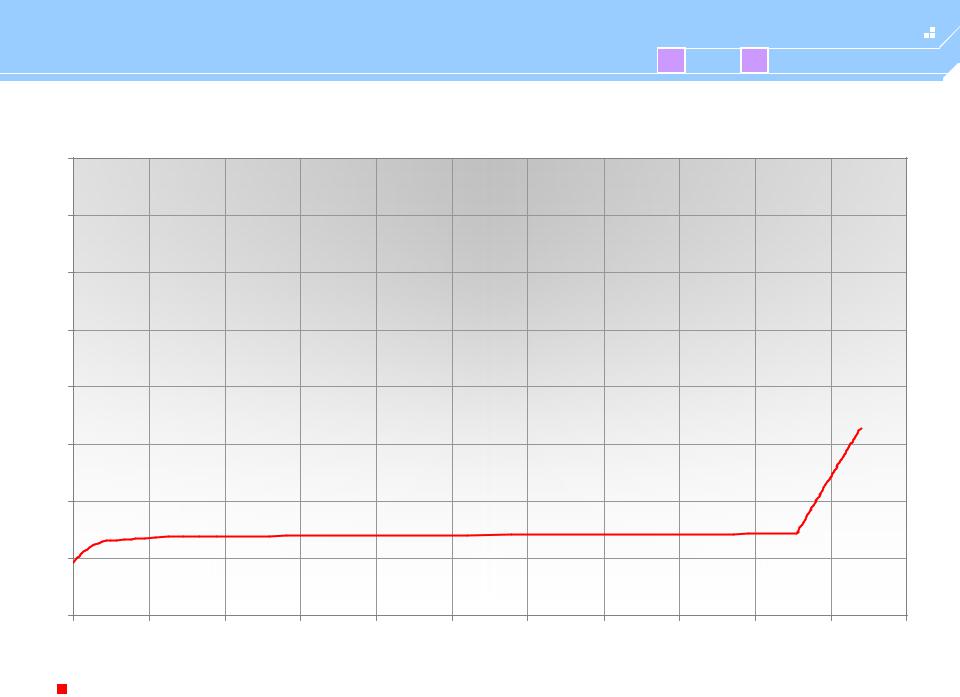

Heat Comparison Curves

Heat Comparison Curves

14,2

14,2

12,0

12,0

1,4

1,4

0,9

0,9

Cold Streams

(Heating Steam Requirement)

Note: Heat steam requirement does not include direct steam streams required in the process.

Desmet / Hytech

30

25,3

25,3

25

|

) |

|

20 |

W |

|

k |

||

|

||

|

( |

|

|

t |

|

14,6 |

a |

|

e |

||

15 |

H |

|

d |

||

|

||

|

n |

|

|

a |

|

|

s |

|

|

u |

|

10 |

o |

|

h |

||

|

T |

|

5 |

|

|

0 |

|

Hot Streams

(Cooling Water Requirement)

Minimum (Pinch)

Actual Required

Maximum (No Economizers)

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

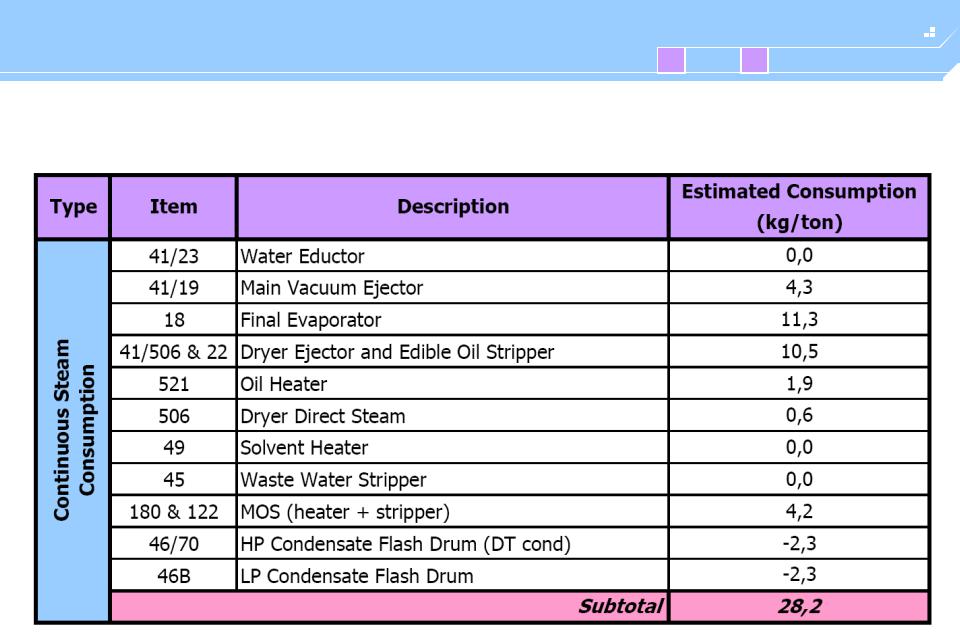

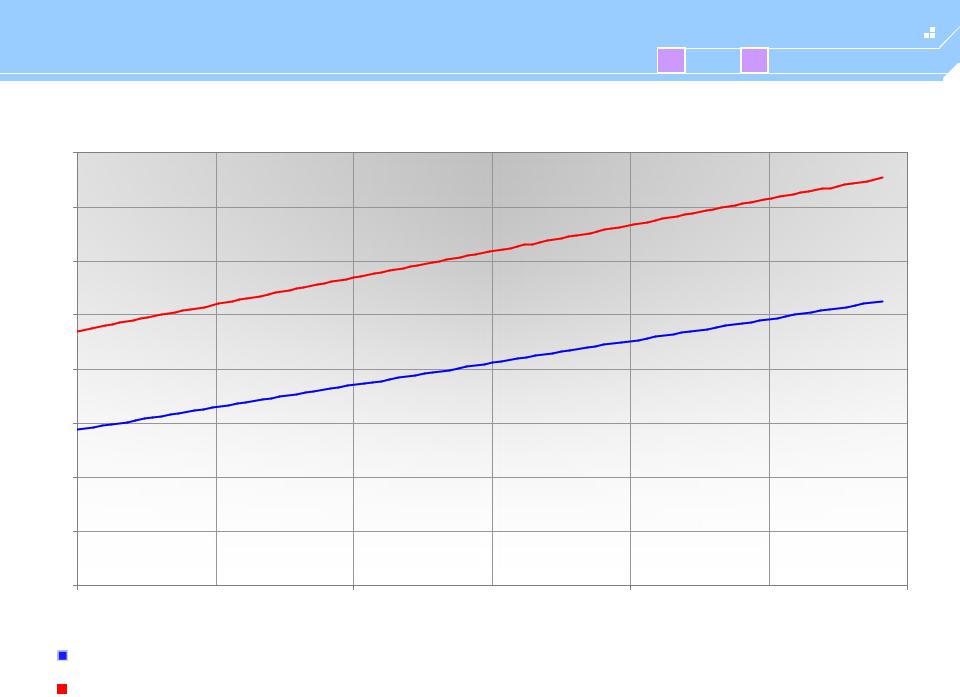

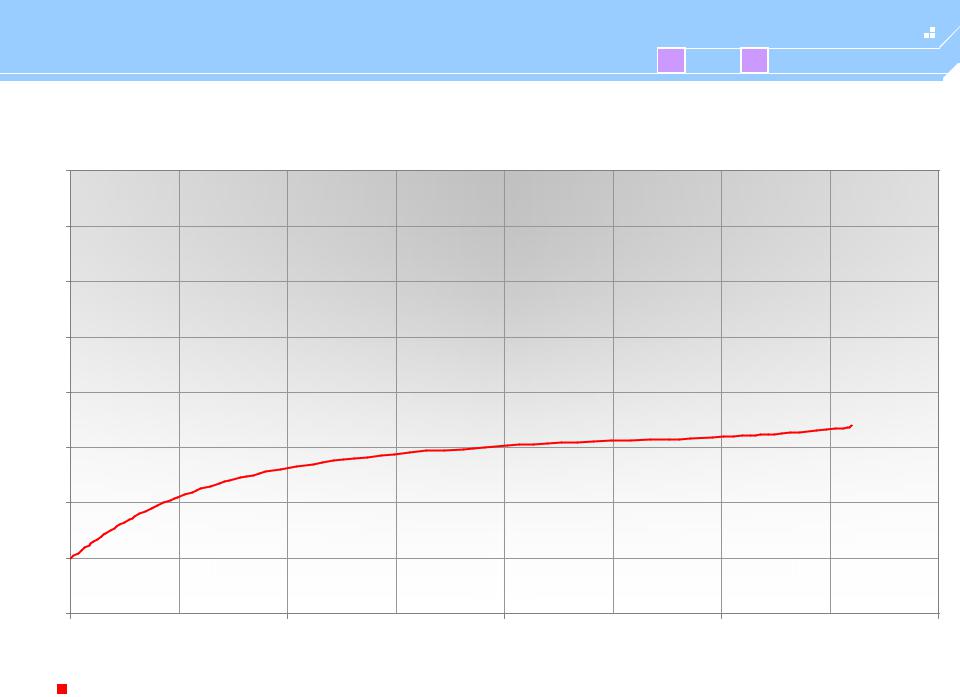

Estimated SEP Steam Consumption

Estimated SEP Steam Consumption

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

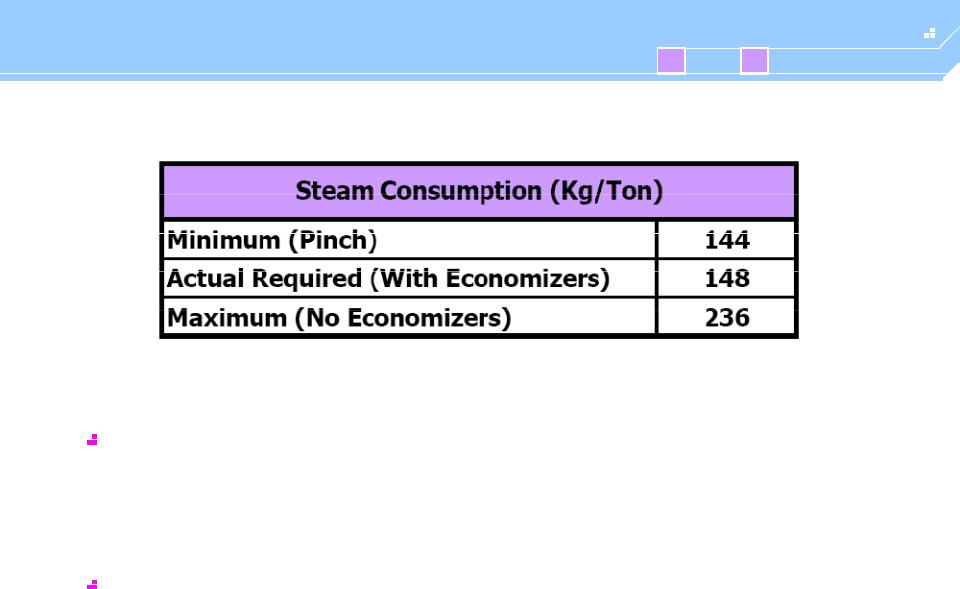

Heat Comparison Curves

Heat Comparison Curves

(*)

(*) Note: In these numbers, direct steam streams are included .

The actual steam comsumption of a standard plant (with all the economizers) is very close to the minimum possible (Pinch).

The actual steam savings of 236 – 148 = 88 Kg/Ton (176 lbs/t) is about 96% of the maximum saving possible of 236 – 144 = 92 Kg/Ton (185 lbs/t).

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

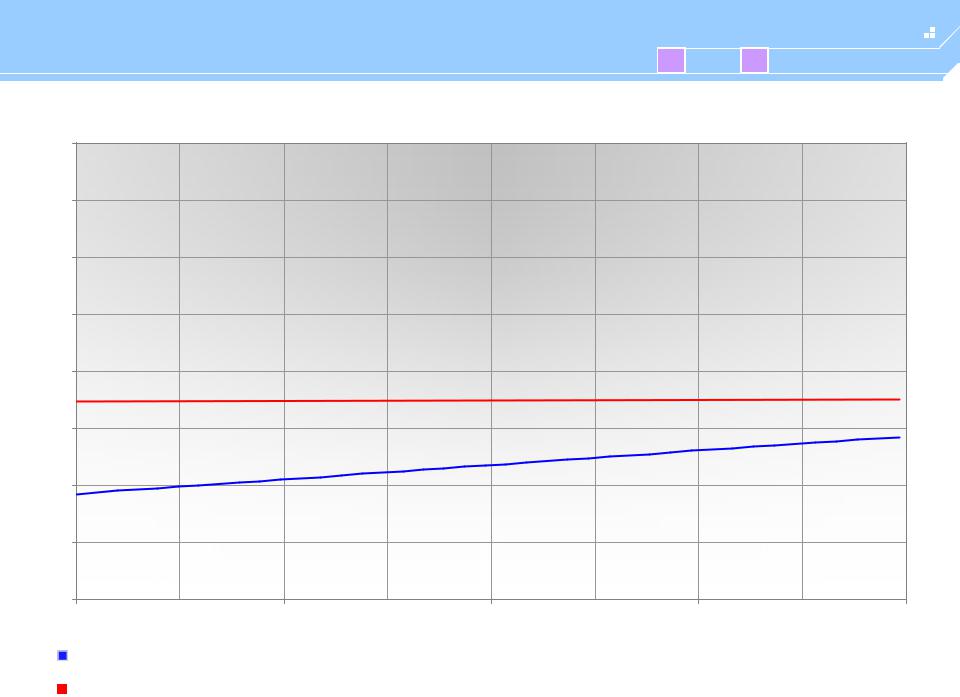

First Stage Evaporator

First Stage Evaporator

105 |

|

|

|

|

|

|

|

|

|

T (ºC) |

|

|

|

|

|

|

|

95 |

|

|

|

|

|

|

|

|

85 |

|

|

|

|

|

|

|

|

75 |

|

|

|

|

|

|

|

|

65 |

|

|

|

|

|

|

|

|

55 |

|

|

|

|

|

|

|

|

45 |

|

|

|

|

|

|

|

|

35 |

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

Thousand Q (kW)

Vapors from DT

Full Miscella

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

2nd Stage Evaporator

2nd Stage Evaporator

105 |

|

|

|

|

T (ºC) |

|

|

95 |

|

|

|

85 |

|

|

|

75 |

|

|

|

|

Pinch Temperature Range |

|

|

65 |

|

|

|

55 |

|

|

|

45 |

|

|

|

35 |

|

|

|

25 |

|

|

|

0,0 |

0,5 |

1,0 |

1,5 |

|

|

|

Thousand Q (kW) |

Miscella from Oil to Miscella Economizer

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

Vacuum Condenser

Vacuum Condenser

105 |

|

|

|

|

|

|

|

|

|

|

|

|

T (ºC) |

|

|

|

|

|

|

|

|

|

|

95 |

|

|

|

|

|

|

|

|

|

|

|

85 |

|

|

|

|

|

|

|

|

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pinch Temperature Range |

|

|

|

|

|

|

65 |

|

|

|

|

|

|

|

|

|

|

|

55 |

|

|

|

|

|

|

|

|

|

|

|

45 |

|

|

|

|

|

|

|

|

|

|

|

35 |

|

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

|

|

|

|

|

|

|

|

|

Thousand Q (kW) |

|

Vapors to Vacuum Condenser

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

Oil to Miscella Economizer

Oil to Miscella Economizer

105 |

T (ºC) |

|

|

|

|

|

|

95 |

|

|

|

85 |

|

|

|

75 |

|

|

|

65 |

|

|

|

55 |

|

|

|

45 |

|

|

|

35 |

|

|

|

25 |

|

|

|

0,00 |

0,25 |

0,50 |

0,75 |

|

|

|

Thousand Q (kW) |

Miscella from First Stage Evaporator

Oil from Edible Oil Stripper

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

Solvent Pre-Heater using Excess DT Vapor

Solvent Pre-Heater using Excess DT Vapor

105

T (ºC)

95

85

75

65

55

45

35

25

0,00 0,25 0,50 0,75 1,00

Thousand Q (kW)

Solvent from Work Tank

Vapors from First Stage Evaporator

Pinch Analysis - Case I

Pinch Analysis - Case I

Desmet / Hytech

DT & Vent Condenser

DT & Vent Condenser

105 |

|

|

|

|

|

T (ºC) |

|

|

|

95 |

|

|

|

|

85 |

|

|

|

|

75 |

|

|

|

|

|

Pinch Temperature Range |

|

|

|

65 |

|

|

|

|

55 |

|

|

|

|

45 |

|

|

|

|

35 |

|

|

|

|

25 |

|

|

|

|

0,0 |

0,5 |

1,0 |

1,5 |

2,0 |

Thousand Q (kW)

Vapors from Solvent Pre-Heater