Пинч / Kemper%20IOMSA%202009%20KC

.pdf

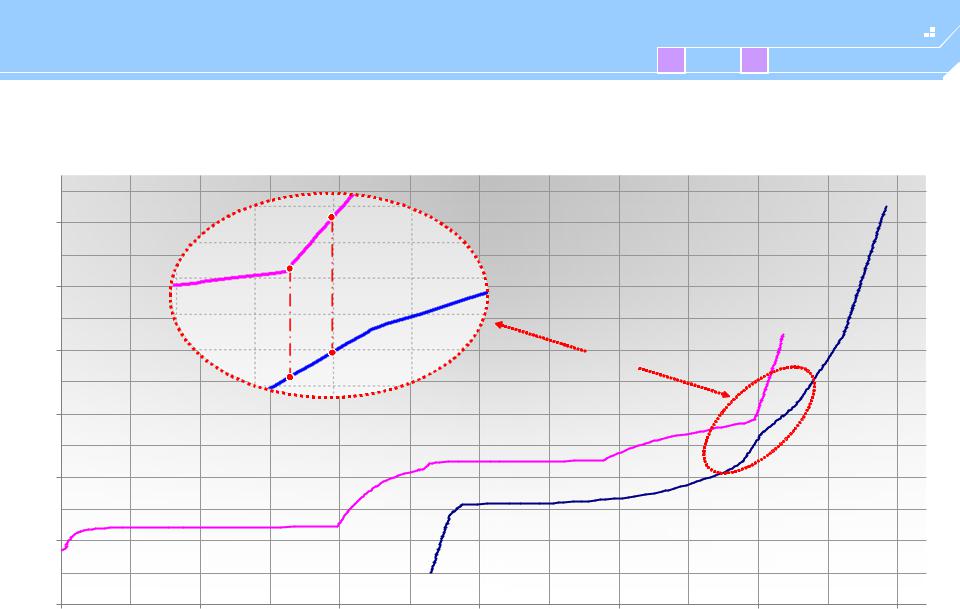

Pinch Analysis - Case II

Pinch Analysis - Case II

Desmet / Hytech

Hot & cold Composite Curves

Hot & cold Composite Curves

135 |

T (ºC) |

|

|

|

|

|

|

77ºC |

|

|

|

|

|

|

74ºC |

|

|

|

|

|

|

|

|

|

|

|

|

115 |

|

|

|

|

|

|

95 |

65ºC |

68ºC |

|

Pinch |

|

|

|

|

|

|

|||

|

|

|

|

Zone |

|

|

75 |

|

|

|

|

|

|

55 |

|

|

Cold Stream |

|

|

|

|

|

|

|

|

|

|

|

Hot Stream |

|

|

|

|

|

35 |

|

|

|

|

|

|

15 |

|

|

|

|

|

|

0 |

5 |

10 |

15 |

20 |

25 |

30 |

Thousand Q (kW)

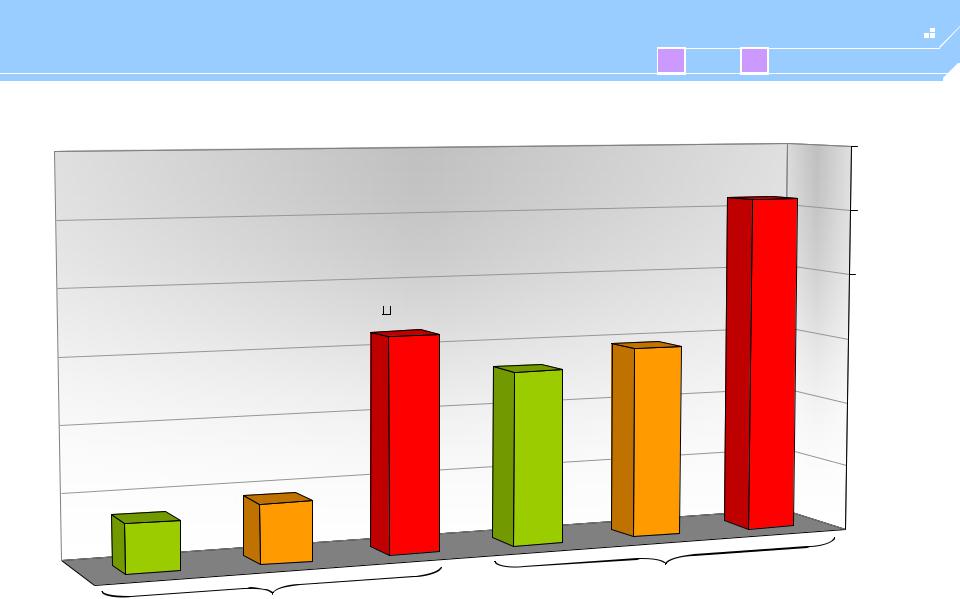

Pinch Analysis - Case II

Pinch Analysis - Case II

Desmet / Hytech

Heat Comparison Curves

Heat Comparison Curves

30

25,9

25,9

25

20

16,3

16,3

14,6

14,6

13,3

13,3

4,5

4,5

3,7

3,7

|

|

|

|

|

|

(kW) |

|

|

|

|

|

15 |

Heat |

|

|

|

|

10 |

Thousand |

|

|

|

|

||||

|

|

5 |

|

|||

|

|

|

||||

|

|

0 |

|

|||

|

|

|

||||

|

Hot Streams |

||

Cold Streams |

(Cooling Water Requirement) |

||

|

|

|

|

(Heating Steam Requirement) |

|

|

Minimum (Pinch) |

|

|

||

Note: Heat steam requirement does not include direct |

|

Actual Required |

|

||

|

|

|

steam streams required in the process. |

|

Maximum (No Economizers) |

|

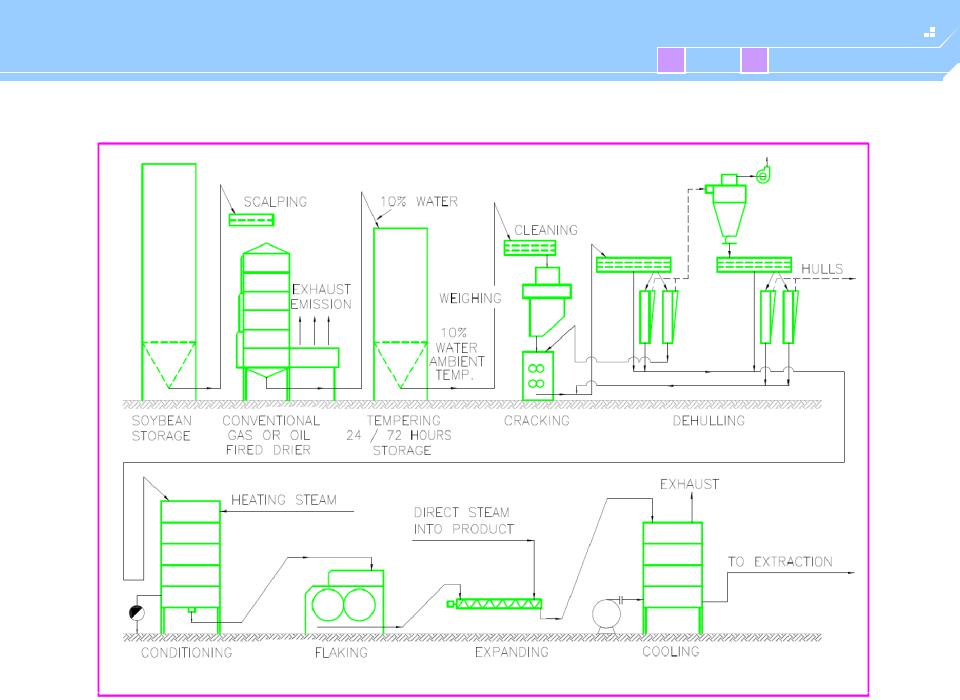

Pinch Analysis

Pinch Analysis

Desmet / Hytech

Case III – For All Sections in the Crushing Plant

Case III – For All Sections in the Crushing Plant

Meal

Dryer

Grain |

Grain |

|

Preparation |

|

SEP |

Edible |

Feed |

Dryer |

|

|

Oil |

||

|

|

|

|

Boiler

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

Conventional Preparation System

Conventional Preparation System

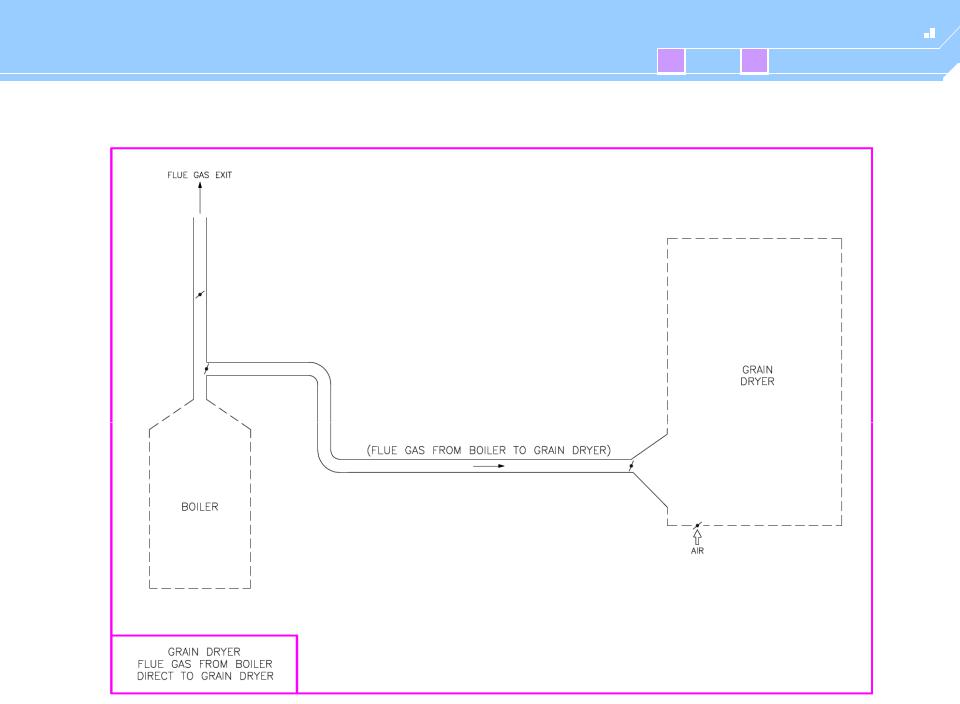

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

Grain Dryer Flue Gas from Boiler Direct to Grain Dryer.

Grain Dryer Flue Gas from Boiler Direct to Grain Dryer.

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

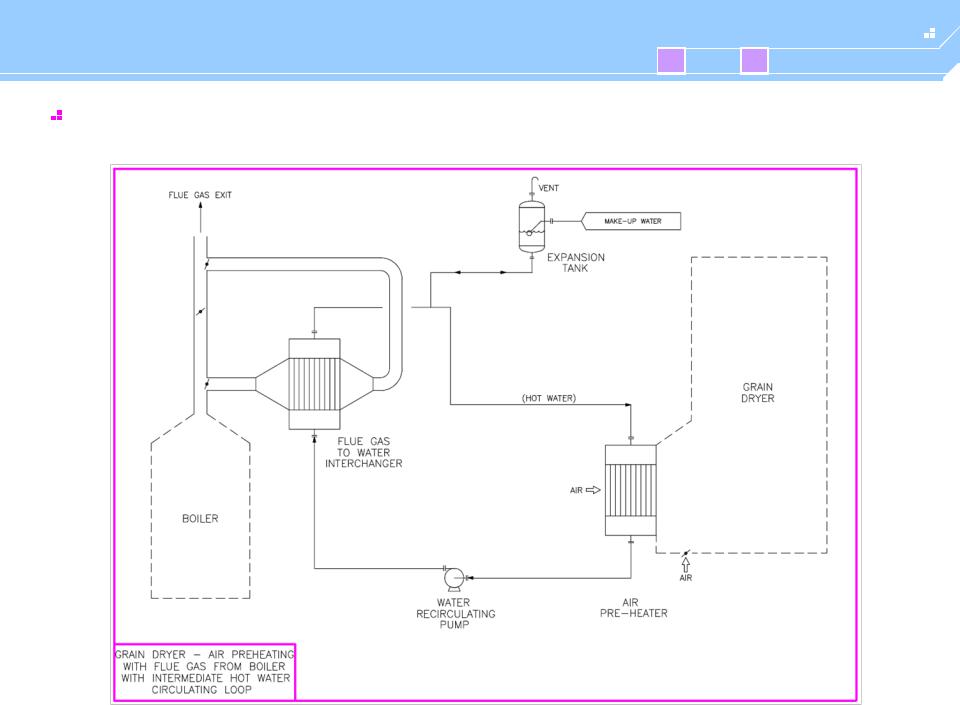

Grain Dryer - Air Preheating with Flue Gas from Boiler with Intermediate Hot Water Circulating Loop.

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

Grain Dryer and Boiler Integration

Grain Dryer and Boiler Integration

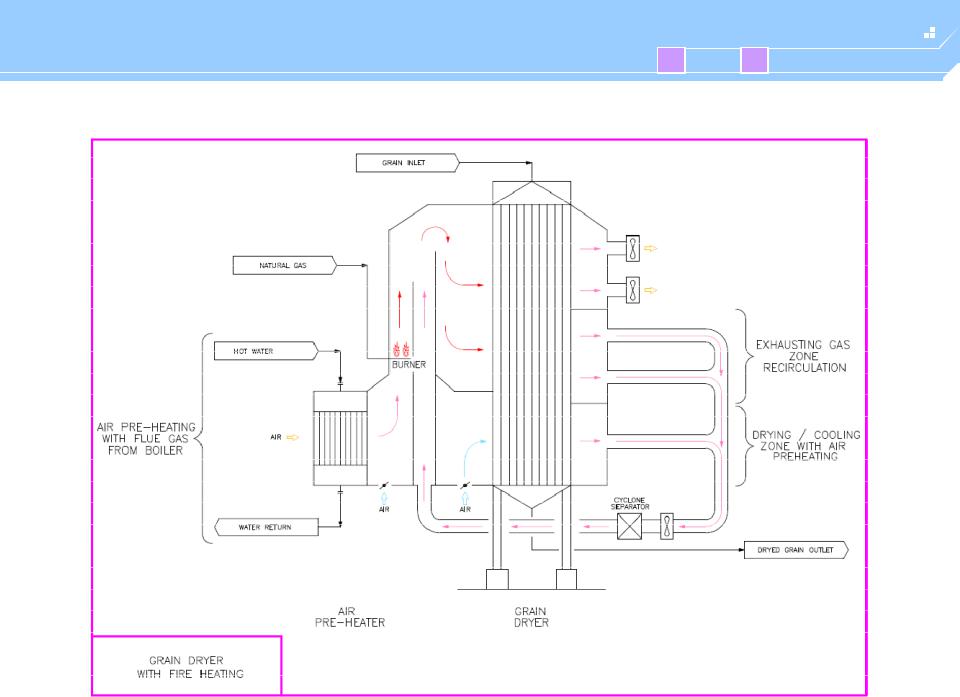

Take advantage of flue gas from boiler, cooling exhausting gas from 180 - 200ºC (356 – 392ºF) to 100 - 110ºC (212 - 230ºF).

For example, using a specific air ratio of 60 m3/h/Ton (750.000 m3/h for 5000 TPD plant capacity). The temperature increase in the inlet air is around 10ºC (18ºF).

Heat fuel saving around 25-30% in Grain Dryer.

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

Optimized Grain Dryer with Fire Heating

Optimized Grain Dryer with Fire Heating

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

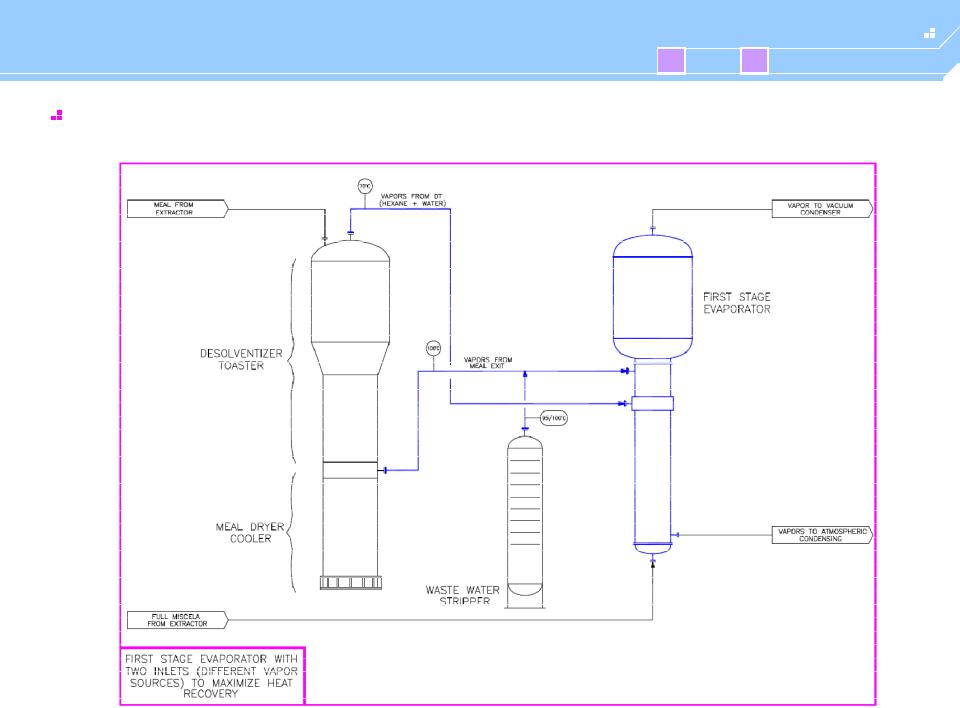

Flash Steam from Meal Steam Dryer recovered in First Stage Evaporator.

Pinch Analysis - Case III

Pinch Analysis - Case III

Desmet / Hytech

Flash Steam from Meal Steam Dryer recovered in First Stage Evaporator.

Flash Steam from Meal Steam Dryer recovered in First Stage Evaporator.

Steam Saving: 4 to 8 Kg per Ton (8-16 lbs/t) Soybean.

Low pressure drop to minimize back-flow potential (safety).

Two vapor inlets: Vapors at 95 – 100ºC (203-212ºF).

Vapors from DT at 70 - 75ºC (158-167ºF).