|

III.3.1 |

Pd-CATALYZED HYDROGENOLYSIS |

1015 |

N |

1 atm H2 |

|

|

Ph |

Pd/C |

NH2 |

|

|

AcOH |

|

|

15−55 °C

O |

N |

O |

N |

|

|

178 |

179 |

90% |

|||

|

|

||||

|

Ph |

|

Ph |

|

Scheme 54

G. HYDROGENOLYSIS OF HALIDES

Pd-catalyzed hydrodehalogenation of halides is a useful method for the removal of halogen atoms. Since other metals are usually not as effective for this reaction (there are exceptions), Pd is therefore the metal of choice. In fact, in order to preserve halogen on a substrate, other metals such as Pt, Rh, and Raney nickel are used in the hydrogenation of other functional groups. In general, the order of reactivity for halide removal is F Cl Br I. Fluoride is usually not hydrogenolyzed except in a limited number of cases. Unless the substrate contains a basic functional group, it is beneficial to add one or more equivalents of a base to neutralize the hydrogen halide formed in order to minimize its poisonous effect on the catalyst. In the absence of a base, rapid slowing down of the reaction may sometimes occur, resulting in incomplete reaction. The following are common bases used in hydrodehalogenation reactions: MgO, carbonates, bicarbonates, hydroxides, acetates, alkoxides, R3N, and DABCO. The useful hydrodehalogenation of acyl halides to aldehydes, the Rosenmund reduction, will not be covered here but will be covered in Sect. VI.2.4.

Besides carrying out dehydrohalogenation in organic solvents, the reaction can also be carried out in water. 1°-Chloride 180 was dehalogenated in an aqueous bicarbonate solution in 94% yield (Scheme 55).[77] Reduction of the corresponding bromide gave an 81% yield.

3°-Chloride 182 was also removed to give 184 as the major diastereomeric product in 83% combined yield (Scheme 56).[78]

|

OH |

H2 |

|

OH |

|

|

20 wt % of |

|

|||

|

O |

Pd/C |

|

O |

|

|

O |

aq. NaHCO3 |

O |

|

|

Cl |

OH |

50 °C, 32 h |

|

OH |

|

HO 180 OH |

|

|

HO |

OH 181 94% |

|

|

|

|

|||

|

|

Scheme 55 |

|

|

|

|

S N |

|

atm H2 |

|

|

N |

|

10 wt % of |

|

|

|

Cl |

Pd/C(5%) |

|

|

|

EtOH, r.t. |

||

|

|

|

||

N |

Cl |

|

|

|

182 |

|

|

|

|

|

|

|

|

|

S |

N |

|

|

|

N |

|

|

||

|

N |

N |

||

|

Cl |

|||

|

+ |

S |

||

|

|

|

||

N |

|

Cl |

N |

|

8% |

184 |

75% |

||

183 |

||||

Scheme 56 |

|

|

|

1016 |

III Pd-CATALYZED CROSS-COUPLING |

The imino chloride in 185 was completely reduced but the bridgehead chloride was not touched. Surprisingly, when the bridgehead chloride was replaced with a methyl group, only 10% of the imino chloride reduced product was observed and the major product was the bislactam from hydrolysis (Scheme 57).[79]

The selective removal of the chloride in the presence of a readily hydrogenated aromatic nitro group was also reported (Scheme 58).[80] Acetonitrile was used as the solvent along with triethylamine as the base for the hydrogenolysis of the chloro group in chloronitrobenzene derivative 187. In EtOAc, however, the nitro group was concomitantly reduced to give aniline 189 in 80% yield.

It was interesting to note that in the process of removing the bromide in 190[81] and 193,[82] the hydroxy and acetoxy groups were also lost (Scheme 59). The primary bromide in 191 was removed in a separate step.

At 75% conversion, selectivity was observed in the reduction of bromoepoxysulfone 195 to give desbromo 196 in 79% yield with only 5% of the epoxide opened product 197 formed (Scheme 60).[83] On prolonged reaction time (15 h) hydroxysulfone 197 was obtained in 72% yield.

The multiple chloro-substituted substrate 198 underwent complete hydrodechlorination in good yield by passing the substrate over Pd/C at 250 °C and atmospheric hydrogen pressure (Scheme 61).[84]

In the hydrogenolysis of the Cbz group in 200, monodechlorination of the trichloroacetamide was also observed to give 201 in excellent yield (Scheme 62).[85]

|

|

|

|

4 atm H2 |

|

|

|

|

|

CH2Ph |

30 wt % of |

|

CH2Ph |

||

|

|

|

|

Pd/C(10%) |

|

|

|

|

N |

O |

N |

O |

|||

|

DABCO, THF |

||||||

|

|

|

|

r.t. |

|

|

|

Cl |

N |

Cl |

|

N |

Cl |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

185 |

|

|

186 |

64% |

||

Scheme 57

O2N

CO2H

|

|

3 h, |

|

|

MeCN |

O2N |

CO2H |

|

|

|

|

|

|

|

|

|

|

Cl |

5 h |

|

187 |

EtOAc |

|

H2 |

188 70% |

5−10 wt % of |

|

Pd/C (5%) |

|

Et3N |

|

80 |

°C |

H2N

CO2H

189 80%

Scheme 58

|

|

|

|

|

|

|

|

|

|

III.3.1 Pd-CATALYZED HYDROGENOLYSIS 1017 |

|||||||||

Br |

OH |

|

|

H2 |

Br |

OH |

|

|

|

H2 |

OH |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

O |

|

Pd/C (5%) |

|

|

O |

|

|

|

Pd/C, Et3N |

O |

|

O |

|

|||||

|

|

|

EtOH |

|

|

O |

|

EtOAc |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

H |

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

OH Br |

|

|

|

|

|

|

|

191 |

|

|

|

|

|

192 |

|

|

|

|

|

190 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

31% over 2 steps |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

AcO |

|

|

|

|

N |

|

|

atm H2 |

|

|

|

AcO |

|

|

N |

|

||

|

|

|

|

|

|

|

10 wt % of |

|

|

|

|

||||||||

|

O |

|

|

N |

NH2 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

||||||||||||||

AcO |

|

|

|

Pd/C (10%) |

|

|

|

O N |

|

|

NH2 |

||||||||

|

|

|

|

|

|

|

|

|

MgO, DMF |

AcO |

|

|

|||||||

|

Br |

|

|

|

N |

N |

|

r.t., 30 h |

|

|

|

|

|

|

N |

N |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

OAc |

|

|

|

|

|

|

|

|

|

|

|||||||

|

193 |

|

|

|

|

|

|

|

|

|

|

|

194 |

72% |

|

|

|

||

|

|

|

|

|

|

|

|

|

Scheme 59 |

|

|

|

|

|

|

|

|||

Br

|

|

O |

H2, BaCO3 |

||

|

|

76 wt % of |

|||

PhCO2 |

OMe Pd/C(10%) |

||||

|

|

|

2 h |

||

|

O2S |

|

|

|

|

|

|

O |

|

|

|

|

O |

|

|

|

O |

PhCO2 |

OMe |

PhCO2 |

OMe |

||

O2S |

+ |

O2S |

OH |

||

|

O |

|

|

|

|

|

195 |

|

|

|

196 |

79% |

|

|

197 |

5% |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scheme 60 |

|

|

|

|

|

|||

|

|

F |

Cl |

|

|

|

atm H2 |

|

F |

|

|

|

|

|

|

|

|

|

|

Pd/C(1%) |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

F |

|

Cl |

|

|

250 °C |

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

|

||

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

198 Cl |

|

|

|

|

|

|

199 65% |

|

|

|

|

|

|

|

|

|

Scheme 61 |

|

|

|

|

|

|||

|

|

O |

|

|

|

|

|

|

|

|

O |

O HO |

|

Ph |

O |

O HO |

|

4 atm H2 |

Ph |

O |

|

|

|||||

|

|

|

|

|

|

||||||||

|

|

O |

|

OCbz |

12 wt % of |

|

|

|

O |

OH |

|||

|

O |

|

Pd/C (10%) |

|

O |

|

|||||||

|

H |

|

|

|

H |

|

|||||||

|

|

|

EtOAc, MeOH |

|

|

||||||||

|

|

HN |

|

|

r.t., 5 h |

|

|

HN |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

Cl |

OH |

|

|

|

|

|

|

|

Cl |

|

OH |

|

|

|

O |

|

|

|

|

|

|

|

|

|

O |

|

|

|

Cl |

|

|

|

|

|

|

|

Cl |

|

|

|

|

|

Cl |

|

|

|

|

|

|

|

|

|

||

|

|

200 |

|

|

|

|

|

|

|

201 |

94% |

|

|

Scheme 62

1018 |

III Pd-CATALYZED CROSS-COUPLING |

The selective monodebromination of geminal-substituted dibromopropane 202[86] was realized in only fair yield, whereas an excellent yield was obtained in the monodebromination of , -dibromolactam 205[87] (Scheme 63).

Dichlorolactam 207 behaved similarly to give the monochlorolactam in 98% yield (Scheme 64).[88]

More interestingly, 50% enantioselectivity was observed in the monodechlorination of, -dichlorolactam 209 using a cinchonine modified Pd catalyst (Scheme 65).[89]

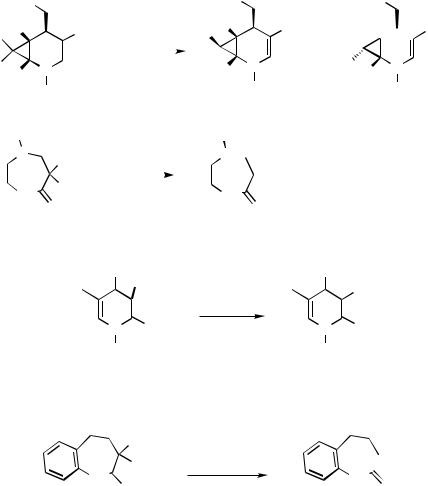

In some cases alkenyl halides can be hydrodehalogenated without the reduction of the resulting olefins. Some examples are presented below (Scheme 66).[90]–[92] These olefinic products can and should eventually be reduced on prolonged reaction time or under more vigorous hydrogenation conditions.

Iodobutadiene 218 was also dehalogenated selectively (Scheme 67).[93]

Ph |

|

|

50 psi H2 |

|

|

50 wt % of |

|

H |

|

|

Pd/C(10%) |

|

CO2Et EtOAc, Et3N |

||

Br |

|

|

r.t., 9 days |

|

|||

|

|

|

|

Br

H N

PhCO

202

EtO2C |

|

H2 |

|

|

Pd/C(5%) |

||

N |

Br |

AcOH, r.t. |

|

|

quinoline |

||

|

|

||

|

|

|

|

Br

HN

O

205

Ph

Cl

Cl

Cl

N  O

O

Ph

207

Cl

Cl

HN  O

O

209

Ph |

Ph |

Br |

H |

CO2Et |

|

H N

PhCO

203 29%

EtO2C

N

Br

Br

HN

206 O 92%

Scheme 63

H2

20 wt % of Pd black benzene, 8 h

Scheme 64

3 atm H2

60 wt % of Pd/BaSO4(5%) THF, Bu3N cinchonine, r.t.

Scheme 65

H

CO2Et

CO2Et

+

Br

H N

PhCO

204 23%

Ph

Cl

N  O

O

Ph

208 98%

HN

Cl

Cl

O

21096%

50% ee

III.3.1 Pd-CATALYZED HYDROGENOLYSIS |

1019 |

O O |

O O |

Br |

+ |

O |

O |

Br |

Br |

211 |

212 |

O2S

I

214

atm H2

4.5 wt % of Pd/C (10%) EtOH, Et3N

atm H2

6 wt % of Pd/C(5%) NaOAc, MeOH quinoline

r.t., 2.5 h

|

|

O |

|

atm H2 |

||

|

Ph |

|

8 wt % of |

|||

|

|

|

|

|

||

|

|

|

|

|

Pd/C(10%) |

|

|

|

|

|

|

|

|

Ph |

|

|

|

|

|

EtOH |

|

|

|

|

|

r.t., 3 h |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Cl

216

I

F

OH

OH

OH

OH

Scheme 66

atm H2 Pd/C(3%)

MeOH, NaOAc r.t., quinoline

218

Scheme 67

O O

O

O

213 56%

O2S

215 96%

O

Ph

Ph

217 85%

F

OH

OH

OH

OH

219 75%

Under catalytic hydrogenolysis conditions, (Z)-N-methoxyarenecarboximidoyl halides 220 gave oximes 221 as the major if not exclusive product. The corresponding (E)-N- methoxyarenecarboximidoyl halides 223 gave nitriles 222 as the major or exclusive product instead (Scheme 68).[94]

With a variety of N-methoxyalkanimidoyl halides 225, good yields of oximes 226 were obtained exclusively.

Halogen-substituted aryl and heterocyclic compounds can also be hydrodehalogenated as easily. With NaOAc as the base, iodopyrrole was deiodinated in quantitative yield (Scheme 69).[95]

Chlorinated acetophenones and benzophenones were hydrodechlorinated selectively under phase transfer conditions without the hydrogenation of the ketone (Scheme 70).[96]

The hydrodehalogenation of -bromonitrobenzene with Pd and H2 to give nitrobenzene is usually unsatisfactory, but under transfer hydrogenation conditions with triethylammonium formate a 91% yield of nitrobenzene was obtained.[97]

Transfer hydrogenation with cyclohexene also removed the chloride in chlorodinitroaniline 233 but one of the two nitro groups was also reduced (Scheme 71).[98]

1020 |

III Pd-CATALYZED CROSS-COUPLING |

|

|

Br |

|

atm H2 |

|

|

|

H |

||||||||

|

|

|

|

|

|

|

3 wt % of |

|

|

|

|

|

|

|||

R1 |

|

OMe |

|

Pd/C |

|

|

|

R1 |

|

|

|

OMe R1 |

||||

|

|

N |

|

t-BuOH, Et3N |

|

|

|

|

N |

|||||||

|

|

|

r.t., 1 h |

|

|

|

|

|||||||||

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

R2 |

|

|

|

|

|

|

|

|

|

R2 |

|

|

|

R2 |

||

|

R3 |

|

|

|

|

|

|

|

|

|

|

|

R3 |

|||

220 |

|

|

|

|

(a) R1 = R3 = H, R2 = OMe 221a 63% |

|||||||||||

|

|

|

|

|

|

(b) R1 = R2 = R3 = OMe |

221b 70% |

|||||||||

|

|

Br |

|

|

|

|

|

|

|

|

H |

|||||

R1 |

|

|

|

|

|

|

|

|

R1 |

|

|

|

|

R1 |

||

|

|

N |

|

|

|

|

|

|

|

|

N |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

OMe |

|

|

|

|

R2 |

|

|

|

|

OMe |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

R2 |

||||

|

R3 |

|

|

|

|

|

|

|

|

|

|

R3 |

|

|

|

|

223 |

|

(a) R1 = R3 = H, R2 = OMe |

224a 11% |

|||||||||||||

|

|

|

(b) R1 = R2 = R3 = OMe |

|

224b |

0% |

|

|

||||||||

|

X |

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

R4 |

OMe |

|

|

|

|

|

R4 |

|

|

OMe |

||||||

225 |

N |

|

|

|

|

|

|

226 |

N |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

(a) R = 2-naphthyl, X = Br |

|

|

76% |

|

|

|

|

(d) R = 4-MeOC6H4, X = Br |

||||||||

(b) R = PhCH2, X = Br |

|

|

78% |

|

|

|

|

(e) R = NC(CH2)9, X = Br |

||||||||

(c) R = 4-AcC6H4CH2, X = Br |

84% |

|

|

|

|

(f) R = PhCH2, X = Cl |

||||||||||

N

N

R3

222a 8%

222b 0%

N

N

R3

222a 69%

222b 88%

85%

69%

64%

Scheme 68

Me |

|

|

|

R |

|

|

|

atm H2 |

|

|

Me |

|

R |

|

|

|

|

|

|

|||

|

|

|

|

|

|

24 wt % of |

|

|

|

|

|

|

R = p-CH3C6H4 |

|||||||||

|

|

|

|

|

|

|

|

Pd/C(5%) |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

MeOH, NaOAc |

|

|

|

|

|

|

|

R = C6H5(CH2)2 |

||||||

Ts |

N |

I |

|

|

|

r.t., 1 h |

|

|

Ts |

|

N |

|

|

|

R = Et |

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R = t-Bu |

||||||||

|

H |

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

227 |

|

|

|

|

|

|

|

|

|

|

|

228 |

100% |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Scheme 69 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

atm H2 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

25 wt % of |

|

|

|

|

|

|

|

|

|

|

||

|

Cl |

|

|

|

|

|

|

Pd/C(5%) |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

aq. KOH, isooctane |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

Aliquat 336 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

50 °C, 2.25 h |

|

|

|

|

|

|

|

|

|

|

||

|

229 Cl |

|

|

|

|

|

|

|

|

|

230 |

|

O 81% |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

O |

|

|

|

|

|

|

|

|||||||||||||

Cl |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

30 °C, 4.5 h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

231 |

|

|

|

|

|

|

|

|

|

|

|

232 |

|

|

|

77% |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

Cl |

O |

|

|

|

|

|

O |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Scheme 70

|

|

|

III.3.1 Pd-CATALYZED HYDROGENOLYSIS 1021 |

||

|

|

NH |

cyclohexene |

NH |

|

|

|

125 wt % pf |

|||

|

|

|

|

||

O2N |

NO2 |

Pd/C(10%) O2N |

NH2 |

||

|

|

|

EtOH |

|

|

|

|

|

reflux, 0.5 h |

|

|

233 |

Cl |

|

|

234 85% |

|

|

|

||||

|

|

|

Scheme 71 |

|

|

Although transfer hydrogenolysis conditions can be used to remove a 1°-chloride such as 235,[99] modification of the reaction conditions also allowed the selective removal of the aryl chloride in 237[100] while leaving the alkyl chloride untouched (Scheme 72).

Other monohalogen transfer hydrogenolysis was seen with trichloroanilide 239[101] and dibromo steroidal derivative 241[102] (Scheme 73).

The hydrogenation of benzaldehyde to the alcohol is usually facile with Pd, but even under the refluxing temperature of the transfer hydrogen conditions, hydrodehalogenation of bromoformylimidazole 243 still provided the formylimidazole in 70% yield (Scheme 74).[103]

Besides observing hydrodehalogenation of aryl bromides under transfer hydrogen conditions, in some cases biaryl coupling is observed. Bromopyridine 245 was homocoupled to give the bipyridyl 246 in 68% yield (Scheme 75).[104]

HCO2NH4 125 wt % of

|

|

HN |

|

|

|

|

|

|

Cl |

|

Pd/C, MeOH |

HN |

|

|

|

|

|

|

|

||||||

|

|

|

|

N |

NH2 |

|

|

reflux |

|

N |

|

NH2 |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

235 |

|

|

|

|

|

HCO2H |

|

|

|

236 |

66% |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

30 wt % of |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Pd/C(30%) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Cl |

|

DMF |

|

|

|

|

|

|

|

|

|

|

|||

|

|

Cl |

237 |

|

|

|

|

|

reflux, 5 h |

Cl |

238 |

|

|

|

|

||||||||||

|

|

|

|

|

|

85% |

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

Scheme 72 |

|

|

|

|

|

|

|

|

|

|

||||

O |

|

O |

|

|

|

HCO2H, Et3N |

O |

O |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

Pd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

CH3CN, NaOAc |

|

|

|

N |

|

|

|

|

|||||||

Cl |

|

|

|

Cl |

|

|

|

80 °C, 3.8 h |

Cl |

|

|

|

|

Cl |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

239 |

Cl |

|

|

|

|

|

|

O |

|

|

|

|

|

240 |

77.6% |

|

O |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HCO2H |

|

|

|

|

|

|

|

|

|

|

||||

Br |

|

|

|

H |

|

|

|

|

33 wt % of |

|

|

|

|

|

|

|

|

H |

|||||||

|

|

|

|

|

|

|

|

Pd/C(10%) |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

H |

H |

|

reflux, 1.5 h |

|

|

|

|

|

|

|

H H |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

DMF |

|

|

|

|

|

|

|

|||||||||||

HO |

|

|

|

|

|

|

|

|

|

|

|

|

|

HO |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

241 Br |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Br |

|

242 70% |

|||||||

Scheme 73

1022 III Pd-CATALYZED CROSS-COUPLING

|

|

HCO2NH4 |

|

|

CHO |

0.5 wt % of |

|

N |

Pd/C(10%) |

||

|

|||

|

MeOH |

||

|

|

||

|

|

reflux |

N Br

243

Scheme 74

HCO2Na

Pd/C, EtOH

r.t., 6 h

N 245 Br

Scheme 75

CHO

N

N 244 70%

N

N

246 68%

H. HYDROGENOLYSIS OF BENZYLIC AND OTHER C—O BONDS

Of all the heterogeneous Pd-catalyzed C—O bond hydrogenolysis reactions, cleavage of benzyl esters is the most facile (Scheme 76).[105]

Benzyl carbonates[106] and carbamates[107] can be hydrogenolyzed as readily with the concomitant release of CO2 (Scheme 77).

O |

|

|

|

|

O |

||||

O |

|

|

|

H2 |

O |

|

|

|

|

|

OCH2Ph |

Pd/C |

|

|

OH |

||||

|

|

|

|

|

|||||

|

|

MeOH |

|

|

|

||||

|

|

|

|

|

|

|

|

||

O HN O |

|

r.t. |

O |

HN O |

|||||

OBu-t |

|

|

|

248 |

OBu-t |

||||

247 |

|

|

|

|

|

96% |

|

|

|

|

|

|

Scheme 76 |

|

|

|

|

||

O |

|

|

|

O |

|

|

|

||

O

N

N

O

O

MeO |

|

|

O |

|

|

|

|

O |

OMe |

||

|

O |

||

O |

249 |

|

|

|

|

||

|

|

|

|

|

|

H2 |

O |

NH |

|

|||

|

|

|

|

|

|

|

||

|

|

12 wt % of |

|

|

|

|

|

|

|

|

Pd/C(10%) |

|

|

|

|

|

|

|

|

EtOAc, r.t. |

|

|

O |

|

||

|

|

|

MeO |

O |

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

HO |

OMe |

|

||

|

|

|

O |

250 98% |

|

|

||

|

|

O |

|

|

|

|

NH2 |

|

|

|

|

NH |

H2, Pd/C |

O |

|||

O |

EtOH, Et3N |

|

||||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

O |

|

|

O |

|

||||

251 |

|

|

|

252 |

92% |

|||

Scheme 77

III.3.1 Pd-CATALYZED HYDROGENOLYSIS |

1023 |

Debenzylation of esters has been carried out under transfer hydrogenation conditions with ammonium formate as the hydrogen source (Scheme 78).[108],[109] Under transfer hydrogenolysis conditions, the vinylogous carbamate 253 also underwent decarboxylation. The N-benzyl was also hydrogenolyzed.

Even 2-phenylethylcarbamate (“homobenzyloxycarbonyl”) can be hydrogenolyzed (Scheme 79).[110]

Although hydrogenolysis of benzyl ethers is slower than benzyloxycarbonyl derivatives, especially when an amine is used as an additive,[111] they are still readily reduced in a variety of solvents (Scheme 80).[112],[113]

In the case of binaphthyl ether 263, the secondary C—O bonds were hydrogenolyzed exclusively to provide the desired binaphthyl diol 264 (Scheme 81).[114]

|

|

|

|

Pd/C(10%) |

|

|

|

|

|

O |

NH4HCO2 |

t-BuO |

O |

t-BuO |

|

|

MeOH |

|||

|

O |

|

O |

|||

|

|

|

100 °C, 0.5 h |

|

||

N |

|

|

|

|

N |

|

O PhCH |

2 |

OCH2Ph |

|

|

O |

H |

|

O |

|

|

254 |

97% |

|

253 |

|

|

|

|||

Scheme 78

H O N

O

100 wt % of |

|

Pd(OAc)2 |

|

NH4HCO2 |

|

MeOH |

H |

r.t., 8 h |

H N

|

|

|

255 |

|

|

|

|

|

|

|

256 |

90% |

|

||

|

|

|

|

Scheme 79 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

atm H2 |

|

|

|

|

|

|

|

|

||

O |

Ph |

|

Pd/C(5%) |

|

|

O |

|

|

|

|

Ph |

||||

|

NH4OAc |

|

|

|

|

|

|

||||||||

t-BuO |

O |

|

t-BuO |

|

|

|

|

O |

|

||||||

|

MeOH, 16 h |

|

|

|

|

|

|||||||||

HN |

|

|

r.t. |

|

HN |

|

|

|

|

|

|||||

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

OH |

|

O |

Ph |

|

|

|

|

|

|

|

O |

|

|

|

|||

257 |

|

|

|

|

|

|

|

|

|

258 |

96% |

|

|||

|

|

|

CH2Ph |

|

H2, Pd/C |

|

O |

|

OH |

|

|

|

|||

O |

O |

|

MeOH |

|

|

|

|

|

|||||||

|

|

|

|

|

r.t., 12 h |

|

|

|

|

|

|

|

|

||

P |

N |

P |

|

|

|

|

N |

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

EtO |

|

|

|

|

|

|

|

EtO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

OEt |

|

|

|

|

|

OEt |

|

|

|

|

|

||||

259 |

|

|

|

|

260 |

95% |

|

|

|

|

|||||

TBDMSO H H |

|

|

H2, Pd/C |

TBDMSO |

|

H |

H |

|

|

||||||

|

|

EtOAc |

|

|

|

||||||||||

|

|

|

|

|

r.t. |

|

|

|

|

|

|

|

|

||

NH |

O |

|

|

|

|

|

|

O |

|

|

NH |

OH |

|||

O |

CH2Ph |

|

|

|

|

|

|

|

262 |

100% |

|

||||

261 |

|

|

|

|

|

|

|

|

|

|

|

|

|||

Scheme 80

1024 |

III Pd-CATALYZED CROSS-COUPLING |

O |

|

5.1 atm H2 |

|

||

|

|

|

|

|

Pd/C |

|

|

AcOH, r.t. |

O

263

Scheme 81

OH

OH

OH

264 90%

Benzyl ethers can be cleaved under hydrogen transfer conditions with many commonly used hydrogen donors such as ammonium formate,[115] 2-propanol,[116] and cyclohexene.[117]

Although the hydrogenolysis of benzyl protecting groups is faster than many other hydrogenolyzable groups, hydrogenolysis of benzyl ethers has been found to be inhibited by 2-methylnaphthalene. In the competitive hydrogenolysis of diether 265, only the naphthylmethyl ether group was cleaved to give the benzyloxy alcohol 266 (Scheme 82).[118] The 2-methylnaphthalene formed continued to inhibit the deprotection of the benzyl group. In fact, the addition of 2-methylnaphthalene alone inhibited the hydrogenolysis of benzyl ethers.

In addition, a catalytic amount of pyridine or ammonium acetate also suppresses the hydrogenolysis of aliphatic O-benzyl protective group.[111],[119] Cleavage of phenolic benzyl ethers, which are more labile than alkyl benzyl ethers, can also be prevented by the addition of 2,2 -dipyridyl (Scheme 83).[120]

The reduction of the stilbene olefin in 267 occurred selectively first while the aromatic nitro group was reduced with longer reaction time. Even prolonged reaction time did not further hydrogenolyze the phenolic benzyl ether.

|

|

|

|

|

|

|

|

|

|

1 atm H2 |

|

|

|

|

|

|

|

||

|

|

O |

|

|

Pd/C(10%) |

|

|

|

O |

|

|

|

|||||||

PhCH2 |

|

O |

|

|

|

|

EtOH, r.t. |

PhCH2 |

|

|

OH |

||||||||

|

|

|

|

|

|||||||||||||||

|

|

265 |

|

|

|

|

|

|

|

|

|

266 |

96% |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Scheme 82 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

atm H2 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

10 wt % of |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Pd/C(5%) |

|

|

|

|

|

|

|

|||

PhCH2O |

|

|

|

|

|

|

|

MeOH PhCH2O |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

NO2 |

|

r.t. 2 h |

|

|

|

|

|

|

NO2 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

267 |

|

|

2,2′-dipyridyl |

268 |

|

84% |

|||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 h |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

PhCH2O |

|

|

|

|

|

|

NH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

269 |

86% |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

Scheme 83 |

|

|

|

|

|

|

|

||||