Chen G.R.Fuzzy PID controllers for industrial applications

.pdfFuzzy PID Controllers for Industrial Applications

G. Ron Chen

Lecture for EE 6452

City University of Hong Kong

Summary

∙Proportional-Integral-Derivative (PID) controllers are the most widely used controllers in industries today

∙Statistics: > 90% controllers in industries are PID or PIDtype of controllers (the rest are programmable logical controllers (PLC))

∙Merits of PID controllers: simple, cheap, reliable, and effective

∙For lower-order linear time-invariant systems and processes, PID controllers have good set-point tracking performance with guaranteed stability

∙Fuzzy logic provides a certain level of artificial intelligence to the conventional PID controllers

∙Fuzzy PID controllers have self-tuning ability and on-line adaptation to nonlinear, time -varying, and uncertain systems

∙Fuzzy PID controllers provide a promising option for industrial applications with many desirable features

Outline of the Presentation

∙Overview of the Fuzzy Logic Technology

∙Overview of Conventional PID Controllers

∙Introduction to Fuzzy PID Controllers

∙Some Successful Examples of Applications

∙Concluding Remarks

Overview of the Fuzzy Logic Technology

Closed-Loop Set-Point Tracking System

Consider the typical set-point tracking system:

r |

+ |

Σ |

e |

Controller |

u |

Plant |

y |

(reference |

(error |

(control |

|

||||

|

|

(output |

|||||

|

signal) |

− |

signal) |

|

signal) |

|

|

|

|

|

|

|

|

|

signal) |

Figure 1 A typical closed-loop set-point tracking system

Objective:

e(t) := r(t) − y(t) → 0 (t→∞)

Approach: Design a fuzzy logic controller (FLC)

e |

Fuzzification |

Fuzzy Rule Base |

Defuzzification |

u |

|

controller |

controller |

||||

|

|

|

|||

input |

|

|

|

output |

|

|

|

Fuzzy Logic Controller (FLC) |

|

|

|

|

Figure 2 General structure of a fuzzy logic controller |

|

|||

temperature |

|

|

b |

c |

y(t ) |

r = 45 o |

d |

|

|

|

|

e(t ) |

|

|

a |

|

|

0 |

|

|

|

t |

Figure 3 Temperature set-point tracking example |

||||

(i) If e > 0 then |

|

|

|

|

e = r − y > 0 |

or |

|

r > y |

|

the output y is at position |

a |

or |

d |

|

(ii) Furthermore, if |

e& < 0 |

then |

|

|

e& = r& − y& = 0 − y& |

|

or |

y& > 0 |

|

(iii) Therefore, the output |

y |

is at position a |

||

Fuzzy Logic Rule Base: |

|

||

R1: |

IF e > 0 |

AND e& < 0 THEN u(t+) = u(t) |

|

R2: |

IF e < 0 |

AND e& < 0 |

THEN u(t+) = − u(t) |

R3: |

IF e < 0 |

AND e& > 0 |

THEN u(t+) = u(t) |

R4: |

IF e > 0 |

AND e& > 0 |

THEN u(t+) = − u(t) |

Fuzzy Controller Design

A. Fuzzification

Purpose: Enable the input physical signal to use the rule base

Approach: Use membership functions |

|

|

|

|

||

1 |

μPS |

μPL |

μNL |

μNS |

1 |

|

|

|

|

||||

0 |

H |

. |

−H |

|

0 |

. |

e, e |

|

e, e |

||||

|

|

(a) |

(b) |

|

|

|

Figure 4 Four membership functions for signals e and e& |

|

|

|

|||

B. Programmable Rule Base

R1: |

IF e = PL AND e& |

R2: |

IF e = PS AND e& |

R3: |

IF e = NL AND e& |

R4: |

IF e = NS AND e& |

R5: |

IF e = NL AND e& |

R6: |

IF e = NS AND e& |

R7: |

IF e = PL AND e& |

R8: |

IF e = PS AND e& |

<0 THEN u(t+) = μP L(e) . u(t)

<0 THEN u(t+) = (1−μPS(e)) . u(t)

<0 THEN u(t+) = −μNL(e) . u(t)

<0 THEN u(t+) = −(1−μNS(e)) . u(t)

>0 THEN u(t+) = μNL(e) . u(t)

>0 THEN u(t+) = (1−μNS(e)) . u(t)

>0 THEN u(t+) = −μPL(e) . u(t)

>0 THEN u(t+1) = −(1−μPS(e)) . u(t)

To implement the FLC on a digital computer:

u(t) = u(kT) and u(t+) = u((k+1)T)

where T is the sampling time.

R1: |

IF e(kT) = PL AND e& (kT) < 0 |

|||||

|

THEN u((k+1)T ) = μ (e(kT)) . u(kT) |

|||||

|

|

|

|

PL |

||

R2: |

IF e(kT) = PS AND e& (kT) < 0 |

|||||

|

THEN u((k+1)T) = (1−μ (e(kT))) . u(kT) |

|||||

|

|

|

|

PS |

||

R3: |

IF e(kT) = NL AND e& (kT) < 0 |

|||||

|

THEN u((k+1)T ) = −μ (e(kT)) . u(kT) |

|||||

|

|

|

|

NL |

||

R4: |

IF e(kT) = NS AND e& (kT) < 0 |

|||||

R5: |

THEN u((k+1)T ) = −(1−μNS(e(kT))) . u(kT) |

|||||

IF e(kT) = NL AND e& (kT) > 0 |

||||||

|

THEN u((k+1)T ) = μ (e(kT)) . u(kT) |

|||||

|

|

|

|

NL |

||

R6: |

IF e(kT) = NS AND e& (kT) > 0 |

|||||

|

THEN u((k+1)T ) = (1−μ (e(kT))) . u(kT) |

|||||

|

|

|

|

NS |

||

R7: |

IF e(kT) = PL AND e& (kT) > 0 |

|||||

|

THEN u((k+1)T ) = −μ (e(kT)) . u(kT) |

|||||

|

|

|

|

P L |

||

R8: |

IF e(kT) = PS AND e& (kT) > 0 |

|||||

|

THEN u((k+1)T) = −(1−μPS(e(kT))) . u(kT) |

|||||

where e& |

(kT) ≈ |

1 |

[e(kT) − e((k−1)T)], with initial conditions |

|||

|

||||||

|

|

|

T |

|||

y(0) = 0, |

e(−T) = e(0) = r − y(0), e& (0) = |

1 |

[e(0) − e(−T)] = 0 |

|||

|

||||||

|

|

|

|

|

T |

|

C. Defuzzification

Select membership functions for the different control outputs from the rule base

μN |

1 μZO |

μP |

|

|

|

|

|

u |

|

–H |

0 |

H |

||||

|

||||||

Figure 5 Typical membership functions for u

Then, the overall control signal, u, is generated by a weighted average formula:

N

åμiui (kT )

|

i=1 |

N |

|

|

|

, (mi ³ 0, åμi > 0) |

|

u((k+1)T) = |

N |

||

å μi |

|||

|

i =1 |

||

|

i=1 |

|

where control outputs ui(kT), i = 1, ..., N=8 are from the rule base.

Overview of Conventional PID Controllers

In the time domain:

(i) P-controller |

u(t) = KP e(t) |

||

|

t |

||

(ii) I-controller |

u(t) = KI òe(τ) dτ |

||

|

0 |

|

|

(iii) D-controller |

u(t) = KD |

d |

e(t) |

dt |

|||

Control gains, KP, KI, and KD, are constants to be determined in the design for set-point tracking and stability consideration.

r |

+ |

e |

|

KP |

u |

system |

y |

|

|

||||||

|

|

– |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

(a) |

Proportional controller |

|

|||

r |

+ |

e |

|

t |

u |

|

y |

|

KIò |

system |

|||||

|

|

– |

|

|

|||

|

|

|

0 |

|

|

|

|

|

|

(b) |

Integral controller |

|

|||

r |

+ |

e |

|

KDd |

u |

system |

y |

|

|

– |

|

dt |

|

|

|

|

|

(c) |

Derivative controller |

|

|||

|

|

Figure 6. |

Conventional PID controllers |

|

|||

In the frequency domain:

(i) P-controller |

U(s) = KP E(s) |

||

(ii) I-controller |

U(s) = |

K I |

E(s) |

|

|||

|

|

s |

|

(iii) D-controller |

U(s) = KD s E(s) |

||

Use Laplace transform L{×} for continuous-time signals:

U(s) = L{ u(t) } and E(s) = L{ e(t) }

Use z-transform Z{×} for discrete-time signals.

r |

+ |

KIò0t |

|

|

|

+ |

u |

y |

|

e |

|

|

|

|

|||||

|

|

|

|

|

|

|

+ |

|

system |

|

|

− |

|

|

|

|

|

|

|

|

|

KP |

|

|

|

|

|

||

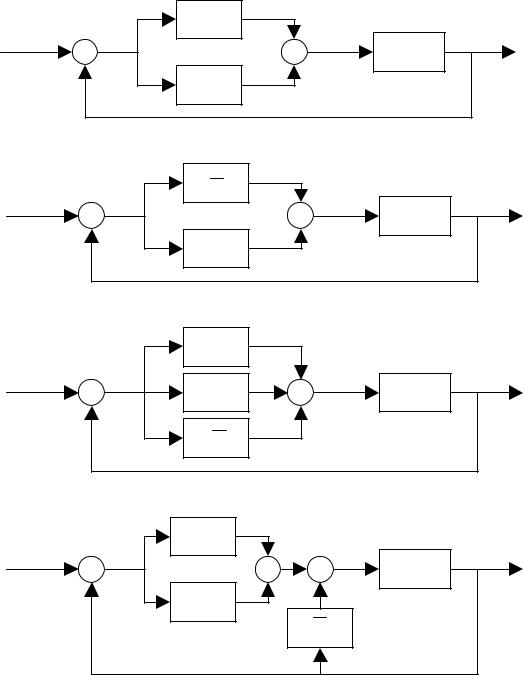

(a) |

PI controller |

|

|

|

|

|

|

|

|

|

|

K d |

|

|

|

|

|

||

r |

+ |

e |

Ddt |

|

|

+ |

u |

y |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

+ |

|

system |

|

|

− |

KP |

|

|

|

|

||

|

|

|

|

|

|

|

|

||

(b) |

PD controller |

|

|

|

|

|

|

|

|

|

|

|

KP |

|

|

|

|

|

|

r |

+ |

e |

|

t |

|

+ |

+ |

u |

y |

|

|

KIò0 |

|

+ |

|

system |

|||

|

|

− |

|

dtd |

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

(c) |

PID controller |

|

|

|

|

|

|

|

|

|

|

K ò0t |

|

|

|

|

|

|

|

r |

+ |

I |

|

|

+ |

|

+ |

u |

y |

e |

|

|

|

||||||

|

|

|

|

|

+ |

|

|

|

system |

|

|

− |

|

|

|

|

− |

|

|

|

|

KP |

|

|

|

d |

|

|

|

|

|

|

|

|

|

|

KDdt |

|

|

(d) |

PI+D controller |

|

|

|

|

|

|

|

|

Figure 7 Some typical combination of P, I, D controllers.