- •Quasiturbine engines

- •Ignite the fuel to create an explosion

- •In Type III, air and fuel are only partially mixed in the combustion chamber. This heterogeneous mixture is then compressed, which causes the temperature to rise until self-ignition takes place.

- •Quasiturbine with Carriages

- •Quasiturbines: Advantages and Disadvantages

Quasiturbine engines

Engine design is at the confluence of three factors: concerns about how car emissions will affect the environment; rising gas prices and the need to conserve fossil fuel resources; and the realization that the hydrogen-powered car – be it powered by a hydrogen fuel cell or by hydrogen internal combustion – will not deliver on its promise in the near future. As a result, many engineers are giving more interest to improving the internal combustion engine.

Engine Basics

The basic principle behind any internal combustion engine is simple: If you put a tiny amount of air and high-energy fuel (like gasoline) in a small, enclosed space and ignite it, the gas expands rapidly, releasing an incredible amount of energy.

The ultimate goal of an engine is to convert the energy of this expanding gas into a rotary (spinning) motion. In the case of car engines, the specific goal is to rotate a driveshaft rapidly. The driveshaft is connected to various components that pass the rotating motion onto the car's wheels.

To harness the energy of expanding gas in this way, an engine must cycle through a set of events that causes many tiny gas explosions. In this combustion cycle, the engine must:

Let a mixture of fuel and air into a chamber

Compress the fuel and air

Ignite the fuel to create an explosion

Release the exhaust (think of it as the by-product of the explosion)

Then the cycle starts all over again.

Essentially, the combustion cycle pushes a piston up and down, which rotates the drive shaft by way of a crankshaft.

While the piston engine is the most common type found in cars, the Quasiturbine engine operates more like a rotary engine. Instead of using piston like a typical car engine, a rotary engine uses a triangular rotor to achieve the combustion cycle. The pressure of combustion is contained in a chamber formed by part of the housing on one side and the face of the triangular rotor on the other side.

The path of the rotor keeps each of the three rotor peaks in contact with the housing, creating three separate volumes of gas. As the rotor moves around the chamber, each of the three volumes of gas alternately expands and contracts. It is this expansion and contraction that draws air and fuel into the engine, compresses it, makes useful power as the gases expand and then expels the exhaust.

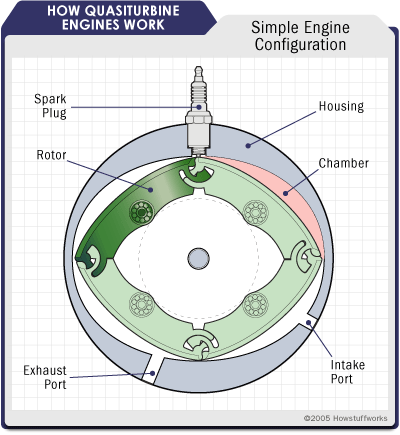

Like rotary engines, the Quasiturbine engine is based on a rotor-and-housing design. But instead of three blades, the Quasiturbine rotor has four elements chained together, with combustion chambers located between each element and the walls of the housing.

The four-sided rotor is what sets the Quasiturbine apart from the Wankel. There are actually two different ways to configure this design – one with carriages and one without carriages.

The simpler Quasiturbine model looks very much like a traditional rotary engine: A rotor turns inside a nearly oval-shaped housing. Notice, however, that the Quasiturbine rotor has four elements instead of three. The sides of the rotor seal against the sides of the housing, and the corners of the rotor seal against the inner periphery, dividing it into four chambers.

|

In a piston engine, one complete four-stroke cycle produces two complete revolutions of the crankshaft. That means the power output of a piston engine is half a power stroke per one piston revolution.

A Quasiturbine engine, on the other hand, doesn't need pistons. Instead, the four strokes of a typical piston engine are arranged sequentially around the oval housing. There's no need for the crankshaft to perform the rotary conversion.

|

In this basic model, it's very easy to see the four cycles of internal combustion:

Intake, which draws in a mixture of fuel and air

Compression, which squeezes the fuel-air mixture into a smaller volume

Combustion, which uses a spark from a spark plug to ignite the fuel

Exhaust, which expels waste gases (the byproducts of combustion) from the engine compartment

Quasiturbine engines with carriages work on the same basic idea as this simple design, with added design modifications that allow for photo-detonation. Photo-detonation is a superior combustion mode that requires more compression and greater sturdiness than piston or rotary engines can provide.

Photo-detonation

Internal combustion engines fall into four categories based on how well air and fuel are mixed together in the combustion chamber and how the fuel is ignited. Type I includes engines in which the air and fuel mix thoroughly to form what is called a homogenous mixture. When a spark ignites the fuel, a hot flame sweeps through the mixture, burning the fuel as it goes. This, of course, is the gasoline engine.

Four Types of Internal Combustion Engines |

||

|

Homogenous Fuel-air Mixture |

Heterogeneous Fuel-air Mixture |

Spark-ignition |

Type I Gasoline Engine |

Type II Gasoline Direct-injection (GDI) Engine |

Pressure-heated Self-ignition |

Type IV Photo-detonation Engine |

Type III Diesel Engine |

Type II – a gasoline-direct injection engine – uses partially mixed fuel and air (i.e., a heterogeneous mixture) that is injected directly into the cylinder rather than into an intake port. A spark plug then ignites the mixture, burning more of the fuel and creating less waste.