Met_OrgSynthesis

.pdf

TEXT 5. ACETYLENE

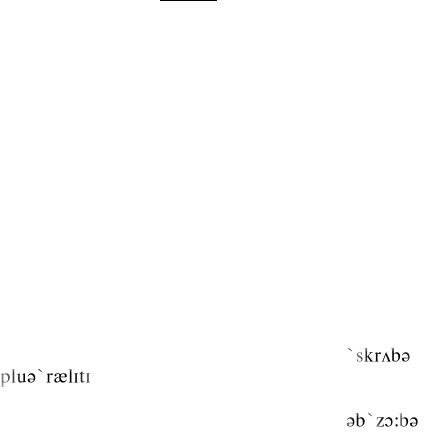

Application. A process for production of acetylene from naphtha and oxygen. Description. Oxygen and vaporized naphtha are preheated separately, mixed

rapidly and fed through a plurality of parallel channels of a burnerblock to the flame room where the reaction is carried out under partial oxidation conditions. The burnerblock prevents flashback or blowoff of the flame and acts as a distributor and stabilizator together with a system of pilots. In the flame room the main part of the naphtha is burnt, the rest (about 30%) is cracked to acetylene and methane. Practically no olefins or higher acetylenes are produced and therefore the separation of acetylene can be done in a very simple and cheap way. The conversion of naphtha and oxygen is complete. The flame reaches an average temperature of 1400° C.

Operating pressure is slightly above atmospheric.

At the end of the flame room the burnergas is cooled rapidly by injection of water. Before the cooled burner-gas can be compressed and separated, soot must be removed in a special water scrubber. The burnergas has the following typical composition (dry basis):

Acetylene Vol. % Hydrogen

Carbon monoxide Carbon dioxide Methane

Higher acetylenes Inerts

The compressed gas (10 atm) passes to the absorber, where acetylene is removed by N-methylpyrrolidone (NMP), a selective solvent which shows a high acetylene/carbondioxide selectivity. After removing CO2 from the rich solvent by stripping, acetylene is recovered by desorption and stripping. Finally the higher acetylene and water are removed by stripping under reduced pressure. The acetylene leaving the NMP-wash has a purity of 99.2% and can be further purified in a sulfuric acid wash to about 99.9%. The offgas is suitable for the production of ammonia or methanol.

Yields. Yields of 23 wt. percent are obtained.

Tasks on the text.

1. |

Memorize the following words and word combinations. |

|

||

1. |

to preheat – предварительно |

14.soot – сажа, копоть, нагар |

||

|

нагревать |

|

15.scrubber [ |

] – скруббер; |

2. |

plurality [ |

] – множество |

газоочиститель; колонна для |

|

3. |

burnerblock – печной блок |

очистки (промывки) газов |

||

4. |

flame room – жаровая камера |

16.absorber [ |

] – абсорбер, |

|

60

5. |

flashback – проскок пламени |

поглотитель |

||

6. |

blowoff – продув, срыв пламени |

17.selective solvent – избирательный |

||

7. |

to crack - крекировать |

|

растворитель |

|

8. |

average temperature [ |

|

18.desorption – десорбция |

|

|

] – средняя температура |

19.to strip – отпаривать, |

||

9. |

operating pressure [` |

] – рабочее |

десорбировать |

|

|

давление |

|

20.stripping – 1) удаление; очистка; |

|

10.burnergas – печной газ |

|

снятие верхнего слоя; 2) отгонка |

||

11.to cool – охлаждать |

|

легких фракций |

||

12.injection – впрыскивание, нагнетание |

21.offgas – отходящий газ |

|||

13.to compress – сжимать |

|

22.yield [ |

] – выход |

|

2. Read the text and decide if the following statements are true or false.

1)In this process acetylene is produced from naphtha and hydrogen.

2)Oxygen and vaporized naphtha are preheated separately.

3)In the flame room the reaction is carried out under complete oxidation conditions.

4)The burnerblock causes flashback or blowoff.

5)The main part of the naphtha is cracked to acetylene and methane.

6)The average temperature of the flame is 1400 C.

7)Operating pressure is slightly higher than atmospheric.

8)Steam is injected to cool the burnergas.

9)It is necessary to remove soot in a special water scrubber.

10)Desorption and stripping recovers acetylene.

3. Put questions to the words in bold type.

1)Oxygen and vaporized naphtha are fed through a plurality of parallel channels of a burnerblock.

2)In the flame room some part of the naphtha is cracked to acetylene and methane.

3)Practically no olefins or higher acetylenes are produced and therefore the separation of acetylene can be done in a very simple and cheap way.

4)The flame reaches an average temperature of 1400 C.

5)At the end of the flame room the burnergas is cooled rapidly by injection of water.

6)The compressed gas passes to the absorber.

7)After removing carbon dioxide from the rich solvent by stripping, acetylene is recovered by desorption and stripping.

8)The acetylene leaving the NMP-wash has a purity of 99.2%.

9)The off-gas is suitable for the production of ammonia or methanol.

4. Describe the process of acetylene production from naphtha and oxygen.

61

Fig. 3. Acetylene production scheme

62

TEXT 6. ACETYLENE (II) (BASF)

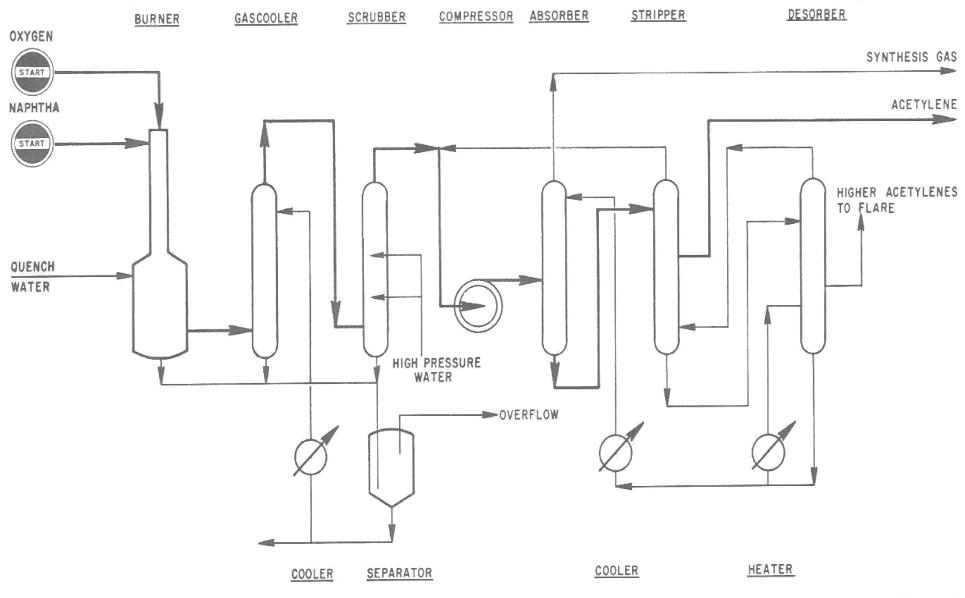

Application. A process for making 99+ percent pure acetylene from natural gas and oxygen.

Description. Oxygen and natural gas are preheated in direct-fired heaters to about 1,200°F. The charge gases are mixed in a molar ratio of 0.60: 1.00 oxygen : methane upon being fed to the burner. The burner is a vertical cylindrical unit comprising three sections: mixing chamber, flame room, and quench chamber. The mixing chamber is specially designed to provide rapid yet thorough mixing of oxygen and methane.

The mixed gases are fed to the flame room through a plurality of ports in a burner block designed to prevent backtravel or blowoff. In the flame, methane is cracked according to the endothermic reaction:

2CH4 → C2H2 + 3H2

The combustion of methane supplies sensible and cracking heats. About one-third of the entering methane is cracked; most of the remainder is burned. Over-all conversion of methane is 90-95 percent; conversion of oxygen is complete. The flame reaches an average temperature of 2,700° F. Operating pressure is slightly above atmospheric.

Residence time is 0.001-0.01 seconds.

The acetylene is cooled rapidly by a series of sprays located in the lower part of the burner. The cooled gases pass directly to a spray chamber where most of the water is condensed. The gases leave the chamber at 100° F and have the following typical composition (dry basis):

Acetylene |

8.5% |

Methane |

4.0% |

Hydrogen |

57.0% |

Higher Acetylenes |

0.5% |

Carbon monoxide |

25.3% |

Inerts |

1.0% |

Carbon dioxide |

3.7% |

Total |

100.0% |

Before the cracked gas can be compressed and separated, residual soot must be removed. Burner trains have a capacity of 25 tons per day. Polyformers are removed by prescrubbing with selective solvent. The clean cracked gas is then compressed to the head pressure (about 10 atmospheres) of the concentration system.

The cracked gas passes from the compressor to the main absorber, where acetylene is removed by a selective solvent which shows a high acetylene: carbon dioxide selectivity. Carbon dioxide is removed from the rich solvent by a flashing and stripping operation. Acetylene is stripped from the solvent by conventional flashing and fractionation. Higher acetylenes and water are removed by stripping under reduced pressure. The product acetylene has a purity of 99+ percent with major impurities being methylacetylene, propadiene and carbon dioxide. 99.9 percent acetylene may be obtained by employing an additional processing step.

Yields. The over-all process yield of acetylene, based on carbon in the natural gas, is 31 percent.

63

Tasks on the text.

1.Memorize the following terms.

1.direct-fired heater – подогреватель

(печь) с огневым подогревом

2. °F, Fahrenheit [

] – по Фаренгейту, по шкале Фаренгейта

] – по Фаренгейту, по шкале Фаренгейта

3.charge [ ] gas – сырьевой газ

] gas – сырьевой газ

4.burner [` ] – факел, высокая

] – факел, высокая

|

труба для сжигания отходящих |

||

|

газов |

|

|

5. |

mixing chamber [` |

] – |

|

|

смесительная камера |

|

|

6. |

quench [ |

] chamber – |

|

охладительная камера

7.port – отверстие

8.backtravel – обратное распространение пламени

9. endothermic [ |

] – |

эндотермический |

|

10.combustion [ |

] – |

сгорание |

|

11.remainder [ |

] – остаток |

12.sensible heat – явная (физическая) теплота, теплота нагрева

13.residence time – время пребывания, продолжительность нахождения

14.spray – распылитель 15.inerts [

] – инертные

] – инертные

компоненты

16.cracked gas – крекинг-газ

17.burner trains – ряд последовательно соединенных факелов

18.polyformer – полиформер

19.selective – селективный

20.head pressure – напорное давление

21.impurities – механические примеси

22.flashing – мгновенное испарение (парообразование)

23.fractionation [

] –

] –

фракционирование, разделение (на фракции); перегонка; ректификация

2.Look through the text and say what is the difference between this text and the previous one.

3.Read the first two paragraphs and say a few words about the burner.

4.Read the following two paragraphs and say what goes on in the flame room.

5.What is meant by residence time?

6.Read the rest of the text and answer the questions.

1)What is a spray used for?

2)Where is a series of sprays located?

3)What goes on in a spray chamber?

4)What composition do gases have after a spray chamber?

5)What is the capacity of burner trains?

6)What is done with residual soot?

7)How are polyformers removed?

8)What is a flashing and stripping operation used for?

9)How is acetylene stripped from the solvent?

10)What is removed by stripping under reduced pressure.

11)What purity has the product acetylene?

12)What are the main impurities?

13)How can acetylene be further purified?

64

Fig. 4. Acetylene (II) production scheme

65

TEXT 7. BUTYLENE AND ETHYLENE (TRIOLEFIN PROCESS)

Application. A process for converting propylene to ethylene and butylene. Description. The Triolefin Process utilizes a disproportionation reaction

whereby relatively low cost propylene can be upgraded to more valuable ethylene and butenes. For every two moles of propylene converted, approximately one mole of ethylene and one mole of butene are produced. The reactor operation is cyclic and carbon is burned off periodically with air mixed with an inert diluent.

Propylene conversion per pass is approximately 40 percent. Unconverted propylene is recycled back to the reactors. Propane and other alkanes can be used as a diluent. Any ratio of propane-propylene is permissible in the unit feed although the internal recycle stream becomes larger as the propane content is increased.

A small percent of the propylene that is converted forms pentenes and heavier material. No more than trace quantities of methane, ethane, isobutene, and butanes are produced in the disproportionation reactors.

Ethylene suitable for polyethylene production can be fractionated easily from the C3 and heavier product from the reactor provided that the feed to the Triolefin Process unit has previously been deethanized. If a high-purity butene product is desired, the reactor feed can be debutanized, leaving nearly pure C3’s, and an additional purification column can be added to the Triolefin Process unit to remove C5’s and heavier. High-purity products can be produced in this way by relatively inexpensive fractionation rather than by difficult ethylene-ethane and butane-butene-2 separations.

Usually more than 90 percent of the butenes from the reactors is butene-2, an excellent feed stock for alkylation to produce high octane motor fuel. Since only trace quantities of C4’s other than normal butenes are present, Triolefin Process butenes are a highly desirable feed stock for dehydrogenation to butadiene.

Reactor onstream cycle times can be extended by reduction of the acetylene and diolefin content of the feed. This can be done easily by selective hydrogenation over a catalyst containing palladium. Catalysts for this purpose are available from well known catalyst suppliers. It is also necessary for the feed to be dry and free of sulfur for satisfactory operation.

Operating Condition. The reactors can be operated at from 0 to 500 psig without affecting the reaction a great deal. The WHSV is practical in the range of 10 to well over 100.

Yields. The conversion of propylene to ethylene and butene is normally over 95 percent.

Tasks on the text

1. Memorize the following terms.

1. triolefin(e) [, |

] – |

10.pentene [ |

] – пентен |

углеводород с тремя двойными |

11.to fractionate [ |

] – |

|

связями; триолефин |

|

фракционировать, ректифицировать |

|

66

2.disproportionation 1)

диспропорционирование (перераспределение атомов или групп между двумя одинаковыми или разными соединениями); 2) самоокисление-самовосстановление

3.disproportionation reaction –

реакция перераспределения; реакция превращения одной молекулы в две другие, отличные друг от друга (окислениевосстановление)

4. butene [` |

] – бутен |

5.to upgrade – облагораживать, повышать качество

6.reactor operation – работа реактора

7. diluent [` |

] – разжижитель; |

разбавитель

8.per pass – за один проход, за цикл

9.feed, feed stock – исходное сырье

12.trace quantities [ ] –

] –

очень малые (едва уловимые) количества

13.to deethanize – деэтанизировать,

отгонять этан |

|

14.dehydrogenation |

|

[ |

] – |

дегидрирование, дегидрогенизация |

|

15.butadiene [ |

] – |

бутадиен

16.onstream time – период непрерывной работы

17.pounds per square inch gage, psig –

избыточное давление, равное

6894,757 Па

18.WHSV, weight hour space velocity

– объёмная скорость (количество нефтепродукта на единицу веса катализатора в час)

2. Read the text. Complete the following sentences, using information from it.

1)The Triolefin Process converts propylene to…

2)In this process a … reaction is carried out.

3)Propylene is converted approximately by 40 % …

4)It is possible to use … of propane-propylene in the unit feed.

5)Methane, ethane, isobutene and butanes are produced in … quantities.

6)If it is necessary to get a high-purity butane product, it is possible to …the reactor feed.

7)Butene-2 is … for alkylation to produce high octane motor fuel.

8)By reducing acetylene and diolefin content of the feed it is possible to extend …

9)This can be achieved easily by selective …

10)A catalyst containing … can be used for this purpose.

3. Find the English equivalents.

Относительно дешевый, более дорогой, на каждые две моли, циклическая операция, допустимый, рециркулирующий поток, содержание пропана, более тяжелое вещество, подходящий для, предварительно, почти чистый, очистная колонна, дополнительный, относительно недорогой, превосходное сырье для алкилирования, моторное топливо с высоким октановым числом, поставщик, свободный от серы (обессеренный), удовлетворительное ведение процесса.

4.Describe the Triolefin Process.

5.Say a few words about reactor onstream cycle time extension.

67

Fig. 5. Ethylene and butylene production scheme

68

TEXT 8. POLYVINYLCHLORIDE

Application. A process for the manufacture of PVC resins from vinyl chloride monomer, catalysts and additives.

Description. Two-step batch polymerization process carried out in two reactors in series. During the first step polymerization proceeds in a liquid medium of vinyl chloride monomer; it is a bead formation phase rate in the range 10 to 12%. For this initial phase, a stainless clad, vertical autoclave equipped with very turbulent agitation is used. Operating pressure and agitation conditions set the particle size distribution and the shape of the bead used thereafter as a seed in the second step.

The second step is a growing phase for the seeds; it is performed in stainless clad designed for efficient agitation of a powdery medium. At the end of the polymerization cycle the unreacted monomer is recovered by condensation and directly reused for further polymerization. PVC resin is then discharged from the horizontal autoclave to a classification unit which screens the product to the desired specification. Oversize amounting to 5-10% of total is reduced in size with an appropriate grinder designed not to affect the product properties

Since mass process produces a dry free flowing resin prior to classification the normal capital expenditures associated in suspension PVC process for dewatering and drying are not necessary. The plant is run by a sequential program; the automatic control of operating procedures results in excellent reproducibility of products manufactured.

Tasks on the text.

1. Memorize the following terms. |

|

|

|

||

1. |

polyvinylchloride[ |

] |

10.autoclave[ |

]– автоклав |

|

|

– поливинилхлорид |

|

11.turbulent agitation [ |

||

2. |

resin [ |

] – смола, полимер |

|

] – турбулентное |

|

3. |

additive– облагораживающая присадка |

перемешивание |

|

||

4. |

batch process – циклический процесс |

|

12.powdery [ |

] – |

|

|

(при котором очередная загрузка |

|

порошкообразный; порошковый |

||

|

аппарата производится после полной |

|

13.to recover – восстанавливать |

||

|

переработки и выгрузки предыдущей |

|

14.classification–сортировка, рассев |

||

|

порции) |

|

|

15.to screen – сортировать; |

|

5. |

in series [ |

] – последовательно, |

|

просеивать |

|

|

по порядку |

|

|

16.grinder [ |

] – аппарат для |

6. |

a bead formation phase rate – скорость |

измельчения или шлифования; |

|||

|

фазы образования шариков |

|

дробилка |

|

|

7. |

to proceed [ |

] – проходить, |

|

17.to run – эксплуатировать; |

|

|

протекать |

|

|

держать в рабочем состоянии |

|

8. |

clad – плакированный, с покрытием, |

|

18.expenditure [ |

] – |

|

|

армированный |

|

издержки, расходы |

||

9. |

stainless clad – с нержавеющим |

|

19.suspension [ |

] – |

|

|

покрытием |

|

|

суспензия; взвесь |

|

68