- •Л.П. Кистол machine-building engineering Учебное пособие

- •Part II Texts for Additional Reading

- •PartI machine-building engineering

- •1 Им: в.Г.. IjJvxoBa

- •Metalworking

- •Memorize the pronunciation of the following words:

- •Figure. Horizontal Milling Machine

- •Memorize the pronunciation of the following words:

- •Abrasion |' эЬге!зп| — шлифовка, снашивание

- •Inner race — внутренний бегунок (канал)

- •14. Text a machine-tools

- •Figure. Engine Lathe

- •In the form of helix about the axis of rotation — в форме спирали по оси вращения text

- •Exercise 1.4. Complete the statements choosing the appropriate variant:

- •Milling cutters

- •Figure. A Slotting Machine

- •General description of lathes

- •Variable ['veariabl] — различный

- •Figure. All Geared Headstock Centre Lathe

- •Types of lathes

- •Part II texts for additional reading

- •3. Silent metals

- •In the fabrication of metal shapes — для придания форм металлу

- •It can be packed to any required shape — ему можно придать любую нужную форму

- •Inspection and measurement

- •Литература

- •Machine-building engineering

Milling cutters

||)j!

Memorize the pronunciation of the following words:

to destroy [dis' troi] — уничтожать, разрушать

cohesion [kou' hi : зп] — сцепление

particle ['pa: tiki] — частица

to push [' puj] — толкать, проталкивать

layer [' leia] — слой

sharp [fa: p] — острый

effort [' efat] — усилие, напряжение

to denote [di 'nout] — обозначать

to penetrate [ 'penitreit] — проникать

conversely [kan'va:sli] — обратно, наоборот

to break [ 'breik] — ломать(ся)

to crumble ['кгдтЫ] — крошить(ся)

preference [' preforsns] — предпочтение

Word combinations for connected reading:

wedge-shaped — клинообразный

lip angle — угол заострения фрезы (угол заточки)

helical teeth — спиральные зубья

smoother performance — более гладкая обработка

left-hand helix — левая спираль

right-hand helix — правая спираль

rough milling operation — черновая обработка

finish milling operation — чистовая обработка

TEXT

The cutting element of any tool is wedge-shaped. The force applied to the tool causes its wedge to enter the material being cut,destroy thecohesion of itsparticles andpush the separatedlayer aside.

The sharper the wedge, i.e., the smaller the angle formed by its sides, the lesseffort is required to feed it into the cut. The angle included between the sides of the wedge is called the“lip angle” and isdenoted by the Greek letter (3 (beta). We can say, therefore, that the smaller the lip angle (3, the more easily the cutter willpenetrate into the metal, and,conversely, the greater the lip angle, the greater the force that must be applied to remove the metal.

Much depends on the material to be cut. If a hard material is to be cut with a tool having a small lip angle (3, the thin edge will be too weak and will either crumble orbreak.

Milling cutters with helical teeth provide muchsmoo-ther performance. Cutter teeth may have either aleft-hand or aright-hand helix. For ordinary milling,prefe-rence is given to right-hand helices. Milling cutters with a small number of teeth are employed forrough milling operations.

Conversely, cutters with a large number of teeth are used for finish milling operations.

Exercise 1.1. Find the Russian equivalents for the following word combinations:

the force applied to the tool; causes the wedge to enter the material being cut; the angle formed by the sides; destroys the cohesion of particles; to penetrate into the metal; to remove the metal; depends on the material to be cut.

заставляет клинок входить в материал, который режут; сила, применяемая к инструменту; угол, образованный его сторонами; снимать метал; разрушает сцепление частиц; зависит от материала, который режут; проникать в металл.

Exercise 1.2. Answer the questions:

What form is the cutting element of any tool?

What does the force applied to the tool cause?

What is called the “lip angle”?

How is the lip angle denoted?

What does the force to be applied to the cutter penetrating into the metal depend on?

When will the thin edge of a tool crumble or break?

What cutters provide much smoother performance?

What helix may cutter teeth have?

Where are cutters with a large number of teeth used?

What cutters are for finish milling operations used?

Exercise 1.3. Find the wrong statements and correct them:

The force applied to the tool destroys the cohesion of material particles.

The sharper the wedge, the greater the angle formed by its sides.

The greater the lip angle, the greater the force to be applied to remove the metal.

If the material to be cut is hard, the thin edge of a tool will crumble.

Milling cutters with helical teeth provide rough performance.

Exercise 1.4. Complete the sentences choosing one of the appropriate variants:

The cutting element of any tool is ...

edge-shaped;

circular-shaped;

wedge-shaped.

The force applied to the tool pushes...

the separated material layer inside;

the seperated material layer aside;

the material particles cohesion.

The more easily the cutter penetrates into the metal...

the smaller the lip angle;

the greater the lip angle.

The thin tool edge breaks if...

a hard material is to be cut with a tool having a great lip angle;

a hard material is cut with a tool having a small lip angle.

Cutters with a large number of teeth are used for ...

rough milling operations;

finish milling operations.

Exercise 1.5. Translate into English:

Режущий инструмент имеет клинообразную форму.

Сила, применяемая на инструмент, разрушает сцепление частиц в металле.

Многое зависит от материала, который подвергается резанию.

Угол заточки — это угол между сторонами лезвия.

Чем острее угол лезвия, тем меньше угол заточки.

Чем меньше угол заточки, тем легче фреза проникает в металл.

Спиральные зубья обеспечивают более гладкую обработку.

Фрезы с небольшим количеством зубьев применяются для черновой обработки.

Text В DRILLING MACHINES

Memorize the pronunciation of the following words:

hole [houl] — отверстие

to machine [ma'Ji :n] — обрабатывать

to handle [ 'hasndl] — регулировать

to apply [a'plai] — применять

to indicate [' indikeit] — показывать, указывать

spindle [spindl] — шпиндель

advantage [3d'va:ntid3] — преимущество to possess [рэ' zas] — владеть, обладать

■ value ['vaslju:] — ценность, значение

to perform [рэ' fo:m] — совершать, выполнять tools [tu: lz] — инструменты gang [gasg] — набор, комплект

column [' kolam] — вертикально-сверлильный станок feed [f i : d] — подача

simultaneously [, simal'teinjasli] — одновременно

Word combinations for connected reading:

drilling machines — сверлильные станки machine-parts — детали машин

for handling the various classes of work — для выполнения различных работ

upright drilling machine — вертикальный сверлильный станок radial drilling machine — радиально-сверлильный станок over the work — над деталью

sensitive drill — быстроходный сверлильный станок с ручной подачей delicate work — мелкая деталь

side by side on a common base — рядом на общем основании

as to speed and feed so that — что касается скорости и подачи так, что

upon a machine — на станке

TEXT

Drilling machines which are used mainly for drilling holes in machine parts, are made in many different types designed for handling the various classes of work.

The upright drilling machines is the type most commonly used, and the nameapplied to this classindicates that the general design of the machine is vertical, and also that the drillspindle is in a vertical position.

The radial drilling machine. — The mainadvantage of a radial machine is that the drill can be movedover the work to any desired position, so that a large number of holes can be drilled in the work without moving it.

81

6-2776

The sensitive drill is a small machine of light construction, whichpossesses sensitive qualities which are ofvalue in drilling holes indelicate work.

The multiple-spindle type is built in both vertical and horizontal design.

It can perform a number of operations on a component without the necessity of changingtools.

Gang Drills. — When a number of single-spindle drilling machinescolumns are placedside by side on a common base and have a common work table, the machine is known as agang drill. Each spindle is independently controlledas to speed and feed so that a number of operations may be performed in succession andsimultaneously upon the machine. In this machine work is moved progressively from one spindle to the next.

Exercise 1.1. Find the Russian equivalents for the following word combinations:

are used mainly; for drilling holes; applied to this class; the general design of the machine; in a vertical position; possesses sensitive qualities; without the necessity of changing tools; is independently controlled; is moved from one spindle to the next.

без необходимости смены инструментов; в вертикальном положении; управляется независимо; движется от одного шпинделя к другому; обладает быстроходными качествами; общее проектирование станка; относящийся к этому классу; в основном используются; для сверления отверстий.

Exercise 1.2. Answer the questions:

What are drilling machines used for?

What type of drilling machines is the type most commonly used?

What position is the upright drilling machine spindle in?

What is the main advantage of a radial drilling machine?

What type has both vertical and horizontal design?

What drilling machine possesses sensitive qualities?

When are gang drills used?

Exercise 1.3. Find the wrong statements and correct them:

The main advantage of a radial machine is that the drill can be moved over the work to the definite position.

The multi-spindle type is built only in vertical position.

In gang drills each spindle is independently controlled.

Drilling machines are used to drill a hole.

The radial drilling machine performs a number of operations on a component without the necessity of changing tools.

The upright drilling machine indicates the drilled holes in delicate work.

The upright drilling machine drills a large number of holes in the work.

Exercise 1.4. Translate into English:

Сверлильные станки используются для сверления отверстий в деталях машин.

Сверло в радиально-сверлильном станке может двигаться над деталью.

Название вертикального сверлильного станка указывает на вертикальное проектирование.

Каждый шпиндель управляется независимо от скорости и подачи.

Быстроходный сверлильный станок не сложен по строению.

Быстроходный сверлильный станок используется, чтобы просверлить отверстия в мелкой детали.

Операции на станке выполняются одновременно.

Радиально-сверлильный станок может просверлить множество отверстий в детали.

6*

83

Text A

THE SHAPER

Memorize the pronunciation of the following words:

shaper [feipa] — поперечно-строгальный станок surface [' sa: f is] — поверхность

stationary [' steijnari] — неподвижный , стационарный

to perform [рэ' fo :m] — совершать, выполнять

angular ['aeggjula] — угольный, угловой

accessory [ask'sesari] — вспомогательный, добавочный

to curve [кэ: v] — изгибать, гнуть

to machine [шэ'/i :n] — обрабатывать

to determine [di' ta: min] — определять

stroke [strouk] — удар, ход

ram [rasm] — плунжер

belt [belt] — пояс, ремень

countershaft [' kauntaja: f t] — контрпривод

hydraulic [hai 'dro: lik] — гидравлический

Word combinations for connected reading:

by successive reciprocating cuts of a tool over the work — последовательным возвратно-поступательным снятием металла режущим инструментом, перемещающимся над деталью with the reference to — относительно in small steps — малыми подачами

plane horizontal surfaces — плоские горизонтальные поверхности

TEXT

A shaper is a machine that forms surfaces by successive reciprocating cuts of a tool over the work. The work is stationary with the reference to

the tool but moves laterally in small steps so that the successive cuts can

be made. Although most of the workperformed on shapers consists ofplane horizontal surfaces, it is also possible to finish vertical andangular surfaces, and, with the proper tools andaccessories, evencurved surfaces may bemachined.

The size of a shaper is determined by the longeststroke of theram. Shapers are driven bybelt from acountershaft, by direct connected motor, or byhydraulic power.

Exercise 1.1. Find the Russian equivalents for the following word combinations:

forms surfaces; angular surfaces; proper tools; curved surfaces; the size of a shaper; the stroke of the ram; by hydraulic power.

ход плунжера; угловые поверхности; обрабатывает поверхности; основные инструменты; с помощью гидравлической силы; размер поперечно-строгального станка; поверхности с изгибами.

Exercise 1.2. Answer the questions:

What is a shaper?

How does the work move?

What parts do shapers consist of?

How may vertical, angular and even curved surfaces be machined?

What is determined by the longest stroke of the ram?

How are shapers driven?

Exercise 1.3. Find the wrong statements and correct them:

A shaper is a machine that forms surface with rotating cutters.

The work is stationary with reference to the tool but moves in large steps.

The work consists of flat horizontal surfaces.

The work performed on shapers includes not only plane surfaces but also angular and curved surfaces.

Curved surfaces are machined with the proper tools.

Shapers are electrically driven by hydraulic power.

The shaper size depends on the longest stroke of the ram.

Exercise 1.4. Translate into English:

Поперечно-строгальный станок обрабатывает поверхности последовательным возвратно-поступательным снятием металла режущим инструментом, перемещающимся над деталью.

Деталь движется малыми подачами.

Деталь неподвижна относительно инструмента.

Размер станка определяется ходом плунжера.

На станке можно обрабатывать даже изогнутые поверхности.

В основном детали, обрабатываемые станком, с относительно плоскими горизонтальными поверхностями.

Text В THE PLANER

Memorize the pronunciation of the following words:

planer f'pleina| — продольно-строгальный станок essentially [i ' senjbli] — особенно, неотъемлемо machining [тэ'/i :niij] — обработка surface [' sa: f is] — поверхность to cut [kAt] — резать

to reciprocate [ri ' siprokeit] — двигаться взад и вперед beneath [bi ' ni : 9] — под, ниже, внизу to mount ['maunt] — крепить, держать

column ['kolam] — вертикально-сверлильный станок, колонка, столбец

to support [sa'po: t] — поддерживать, опираться to comprise [kam'praizj — заключить в себе, охватывать slide ['slaid] — скользить feed [f i : d] — подача

pain

Word combinations for connected reading:

plane surface — плоская поверхность

high output — высокая производительность

a reciprocating table — движущийся взад и вперед стол

cross bar — поперечина

tool heads — инструментальные головки

motions for feed or cut take place — движения для подачи или обработки режущим инструментом происходят hand-operated — управляемый вручную rack-and-pinion drive — зубчато-реечный привод spiral drive — привод винтовыми колесами

TEXT

Planers areessentially formachining plane surfaces which are largerthan can becut or reached on the shaper. The modern planer with modem electric controls has ahigh output.

6

10

11

Figure. A Planer

1 —bed; 2 — table;3—tool;4—hinge pin; J — tool head;6 —bar; 7 — columns;8— control panel;9— motor;10— reversing lever;11—striking dogs

The planer has a reciprocating table which travels beneath a cross

bar on which the tools heads aremounted. Normally one or twotool heads are mounted on the cross bar, but additional tools, generally for cutting vertical faces, may be mounted on thecolumns supporting the cross bar. The usual design shown in Figurecomprises two vertical columns between which the table reciprocates. The cross bar is so mounted that it canslide vertically on these columns. Allmotions for feed or cut take place either by dropping the cross bar, moving the tool head across the cross bar, or lowering the tool holder mounted on the tool head. The first two of these motions are generally power orhand- operated but the last is often hand-operated only.

The table is normally operated by some form of rack-and-pinion orspiral drive.

Modern high-speed planers are now fully electrified.

Exercise 1.1. Find the Russian equivalents for the following word combinations:

for machining plane surfaces; travels beneath a cross bar; the tool heads are mounted; additional tools; for cutting vertical faces; supporting the cross bar; the table reciprocates; can slide vertically; across the cross bar.

крепятся инструментальные головки; вспомогательные инструменты; стол движется взад и вперед; движется под поперечиной; поддерживающие поперечину; через поперечину; для резания вертикальных поверхностей (граней); для обработки плоских поверхностей; может скользить вертикально.

Exercise 1.2. Answer the questions:

What are planers?

What has a modern planer?

How does a reciprocating table travel?

What is on a cross bar mounted?

What are additional tools used for?

What does the design of a planer comprise?

What supports the cross bar?

How is the cross bar mounted?

How can the motions of the planer take place?

Are modern planers fully electrified?

What are the main motions of a planer?

Exercise 1.3. Find the wrong statements and correct them:

Planers are machine-tools used for grinding flat surfaces.

Planers machine larger surfaces than can be cut on shapers.

The tool heads are mounted on a cross bar.

The design comprises two horizontal columns beneath which the table reciprocates.

Additional tools are mounted on the vertical faces.

All motions for feed and cut take place either by raising the cross bar, or lowering the tool holder mounted on the tool head.

The motions can be only hand-operated.

Exercise 1.4. Complete the statements choosing the appropriate variant:

Planers are for machining...

curved surfaces;

flat surfaces;

plane surfaces.

The reciprocating table moves beneath...

tool head;

a cross bar;

columns.

The usual design comprises...

three horizontal columns;

two vertical columns;

a reciprocating table.

The cross bar can slide...

horizontally;

vertically;

essentially.

Exercise 1.5. Translate into English:

Продольно-строгальные станки сейчас оснащены электроприводом.

Часто станки управляются вручную.

Продольно-строгальный станок состоит из движущегося взад и вперед стола, на котором крепятся инструментальные головки.

Стол крепится между двумя вертикальными частями.

Инструментальные головки крепятся на поперечине.

Вертикальные части поддерживают поперечину.

Продольно-строгальные станки обрабатывают плоские поверхности.

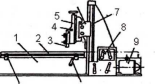

Text В THE SLOTTER

Memorize the pronunciation of the following words:

slotter ['slots] — долбежный станок

to look upon — рассматривать

to machine [шэ'/i :n] — обрабатывать

surface ['sa:fis] — поверхность

casting ['ka: stir]] — каркас, отливка

forging [' f о: d3it] | — ковка

virtue [' va: t ju: ] — сила, действенность

pivoted ['pivatid] — стержневой, вращающийся

keyway ['ki:wei] — шпоночная канавка

square [' skwea] — квадратный

hole [houl] — отверстие

clutch [klAtJ] — сцепление

T-slot [Ti : slot] — Т-образный паз (прорезь)

to clamp [klsemp] — скреплять, зажимать

to mount ['maunt] — крепить, держать

slide [slaid] — салазки

intermittent [,inta'mitant] — перемежающийся

feed [f i : d] — подача

to rotate [, rou' teit] — вращать

axis [' seksis] — ось

pulley [ 'puli] — шкив, блок

gear-box (' gioboks] — зубчатая коробка

TEXT

The slotting machine shown in the figure may be looked upon as a vertical shaping machine. Itmachines the internal surfaces of acasting orforging and can do circular work byvirtue of itspivoted table. Originally