Therapeutic Micro-Nano Technology BioMEMs - Tejlal Desai & Sangeeta Bhatia

.pdf174 |

TEJAL A. DESAI ET AL. |

local vascularization. Studies by Kulseng et al. [7] have also suggested the possibility that xenografts are killed by local accumulation of inflammatory cells, mediated by the release of antigens from encapsulated cells which bind nonspecifically to the outer capsule surface and trigger complement activation and a subsequent local inflammatory response. Weber and colleagues [31–35] also presented evidence that leakage of antigens out of the capsule incited macrophage activation and cytokine release resulting in pericapsular inflammation and fibrosis and cytokine-mediated islet destruction.

Based on these studies, it seems that successful immunoisolation will require membranes that not only provide protection of the encapsulated tissues from the host immune system but also have properties that diminish the release of xenogeneic antigens through reduced pore size and surface properties that prevent nonspecific adsorption. It is thought that current membrane technology has reached a plateau and molecular weight cut-offs cannot be made tighter without compromising the health of the implants [66]. Although it may be technically possible to eliminate the escape of shed antigens, such a diminished pore size would most probably limit the diffusion of essential nutrients to the encapsulated cells. Some have suggested that we must combine new membrane immunoisolation technologies (having tighter cut-offs) with the immunomodulation of cell sources themselves [67]. In addition, we believe that the combination of new membrane architectures with surface modification strategies that resist non-specific adsorption will also be effective.

Current polymeric biocapsules have not been able to achieve uniform pore size membranes in the tens of nanometer range. These membranes, due to their polymeric nature, have found that meeting cut-off requirements is quite difficult, due to the broad pore size distribution of real membranes. Even if only 1% of pores were larger than the cut-off goal, the pores would allow the passage of antibodies, complement, and cytokines in sufficient amounts to initiate immunorejection pathways [1]. The immune system is quite specific and as such, a membrane that attempts to circumvent the immune system should be specific and precise as well. Moreover, effective methods for encapsulation are needed which do not damage cells during the process. For example, processes involving vacuum, high shear, organic solvent, or free radicals are not compatible with cell viability. Processes that produce less than complete coverage of the cells will result in host immune sensitization by cellular means followed by humoral destruction.

10.1.3. Microfabricated Nanoporous Biocapsule

The silicon-based nanoporous biocapsule is achieved by applying fabrication techniques originally developed for Micro Electro Mechanical Systems (MEMS), and represents one of first therapeutic applications of micro and nanotechnology in biomedicine (bioMEMS) [36–41]. Utilizing bulk and surface micromachining and microfabrication, membrane-based biocapsules can be engineered to have uniform and well-controlled pore sizes, channel lengths, and surface properties [42]. We have developed several variants of microfabricated diffusion barriers, containing pores with uniform dimensions as small as 7 nanometers [43].

The control of pore size down to tens of nanometers, coupled with modification of the outer biocapsule wall to prevent protein binding may be able to overcome some of these immunological challenges and at least hinder the passage of small cytokines and cell-secreted antigens. This control over membrane parameters has been suggested by other

NANOPOROUS MICROSYSTEMS FOR ISLET CELL REPLACEMENT |

175 |

groups as being the only way to achieve immunoisolation [44–45]. Due to the fact that we can control the geometry and length of the diffusion path (straight vs. L-shaped), it is thought that we can have greater control over the diffusion rate of small molecules. Furthermore, improved dynamic response of islets tissue can be obtained due to the reduced membrane thickness (6–9 μm) of microfabricated membranes compared to polymeric membranes (100–200 μm) [1]. It is important to retain rapid intrinsic secretion kinetics, in particular first phase insulin release, so as to provide physiological feedback control of blood glucose concentrations. Moreover, we have shown that our nanoporous membranes display little non-specific protein/peptide adsorption or fibrosis, which may be critical for limiting the local inflammation due to a cell-secreted antigen response [54].

Another important consideration is the ability to insert islets into the device in situ. By incorporating a refilling/recharging port into the design, we have the unique ability to introduce islet after the devices have been implanted and after neovascularization has taken place. Moreover, the ability to remove cells after implantation allows for recharging of the device if new cells are needed long term. This is also a critical aspect in the safety of our device, in that cells can be added/removed in the case of too much or too little insulin output.

In addition, the design of the microfabricated membrane may be advantageous due to the ability to create a bi-level pore structure. The outer openings can be 2 by 2 microns while the inner diffusion channels can be designed to have a minimum dimension of tens of nanometers. Studies by Brauker et al. [46] revealed that neovascularization at the membrane-tissue interface occurred in membranes that had pore sizes large enough to allow complete penetration by host cells (0.8–8 microns pore size). When the vascularization of the membrane-tissue interface of 5-microns-pore-size polytetrafluoroethylene (PTFE) membranes was compared to 0.02-microns- pore-size PTFE membranes, it was found that the larger pore membranes had 80–100-fold more vascular structures. The increased vascularization was observed even though the larger pore membrane was laminated to a smaller pore inner membrane to prevent cell entry into the prototype immunoisolation device. We have observed similar phenomena with our microfabricated membranes.

Compared to alginate systems, micro and nanofabrication technology offers control of pore dimensions, short distance through pores, durable materials, and is refillable and removable. Compared to existing membrane implants, microfabricated nanoporous membranes can allow for precise control of pore dimensions (small and uniform) and the potential for active diffusion. Moreover, the ability to integrate other “smart” capabilities such as multicompartmental structure; local release of immunosuppressive drugs; biosensor incorporation, self-cleaning capabilities; and modulation of angiogenesis via surface architecture or immobilized growth factors, is extremely attractive.

10.2. FABRICATION OF NANOPOROUS MEMBRANES

The micromachined immunoisolation biocapsule concept started with the development of a membrane with highly defined pores into a structure that would allow the microencapsulation of cells for immunoisolation. The basic technology that was developed for the nanopores themselves was the use of a sacrificial oxide sandwiched between silicon layers, thus defining a space that could be opened by a subsequent etching of the oxide in

176 |

|

|

|

|

|

TEJAL A. DESAI ET AL. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(a) |

|

|

(c) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

t |

|

|

|

|

|

l |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(b) |

(d) |

FIGURE 10.1. Process flow diagram for creating nanochannels using microfabrication technology.

HF. To make the complete immunoisolation capsule, the silicon substrate is etched up to the membrane, leaving a cavity in the wafer with an encapsulating immunoisolation membrane [11]. The design has been refined with the help of iMEDD, Inc. for the past several years to optimize and scale up the production of the nanoporous biocapsules. The biocapsule, in its current state, consists of a refillable housing with the desired cells contained within the housing. In general, photolithography is not amenable to the fabrication of pores with dimensions smaller than 0.35–1 micrometer. To reach a desired pore size in the tens of nanometers range, we have developed strategies based on the use of a sacrificial oxide layer, sandwiched between two structural layers, for the definition of the pore pathways [43]. This strategy encompasses a multitude of viable embodiments for the biocapsules [36, 43].

The overall process is shown schematically in Figure 10.1 (Desai et al., 2000a). The first step is the etching of the support ridge structure into the substrate (not shown in the figure). These ridges provide mechanical rigidity to the final membrane structure. A low stress silicon nitride layer (nitride), which functions as an etch-stop, is then deposited. A polysilicon film, that acts as the base structural layer (base layer), was deposited on top of the etch-stop layer. Because the etch-stop layer is very thin, the structural layer gets deposited down into the support ridge, which will remain after the membrane is released and the etch stop layer is removed.

The next etch step is the etching of holes in the base layer (10.1a), which defines the overall shape of the pores. The holes are etched through the polysilicon by chlorine plasma, with a thermally grown oxide layer used as a mask. After the pore holes are defined and etched through the base layer, the pore sacrificial oxide is grown on the base layer (10.1b). The sacrificial oxide thickness determines the pore size in the final membrane, so control

NANOPOROUS MICROSYSTEMS FOR ISLET CELL REPLACEMENT |

177 |

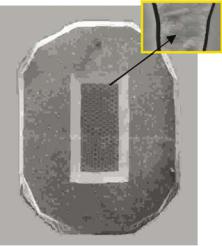

FIGURE 10.2. Top view of nanoporous membrane with close-up of pores.

of this step is critical to reproducible pores in the membranes. The necessary control is accomplished by the thermal oxidation of the silicon in dry oxygen. Thermal oxidation of polysilicon allows the control of the sacrificial layer thickness of less than 0.5 nm across the entire wafer. Limitations on this control can come from local inhomogeneities in the polysilicon, such as the initial thickness of the native oxide (especially for polysilicon), the grain size or density, and the impurity concentrations. To mechanically connect the base polysilicon with the plug polysilicon, which is necessary to maintain the pore spacing between layers, anchor points are defined in the sacrificial oxide layer. After the anchor points are etched through the sacrificial oxide, the plug polysilicon is deposited to fill in the holes (10.1c). The plug layer is then planarized down to the base layer, leaving the final structure with the plug layer only in the base layer openings. Chemical mechanical polishing is used to planarize the polysilicon, leaving a very smooth surface with the pores exposed.

A protective nitride layer is then deposited on the wafer (completely covering both sides of the wafer). This layer is completely impervious to the KOH chemical etch used to release the membranes from the bulk silicon. The backside etch windows are etched in the protective nitride, exposing the silicon wafer in the desired areas, and the wafer is placed in an 80◦C KOH bath to etch. After the silicon is completely removed up to the membrane (as evidenced by the smooth buried etch stop layer), the protective, sacrificial, and etch stop layers are removed by etching in HF (10.1d).

The structure and pore size of these membranes were verified via scanning electron microscopy (figure 10.2). The dimension of the membrane, including the support ridge, are 6 × 8 mm. The active area measures 3.5 × 2 mm and has a thickness, or channel length, equal to 5 μm. The overall porous surface is equal to 7 mm2. Pores can be annular (C shaped) or linear, organized in parallel arrays along the membrane major dimension, separated by 5 μm long anchor points. Regardless of the pore width, the length is fixed at 45 μm and there are 10,000 pores per mm2. Hence, the total pore area increases linearly with the pore size.

178 |

TEJAL A. DESAI ET AL. |

Protective screen

Gasket

Silicon membrane

Injection ports

FIGURE 10.3. Schematic of Biocapsule Assembly.

10.3. BIOCAPSULE ASSEMBLY AND LOADING

A schematic of the biocapsule assembly is shown in figure 10.3. The biocapsule is assembled with latex gaskets between the membrane and plastic body. To eliminate the introduction of air bubbles, assembly is done underwater in a glass 125 mm × 75 mm dish. It is important to loosely assemble the biocapsule to allow for expansion of plastic parts during sterilization. The submerged biocapsule is sterilized in the dish by autoclaving at 121◦C for 15 minutes. The biocapsule is allowed to cool in a tissue culture hood, and a sterile filling tube will be attached to one port. Approximately 40 ul of islet/alginate/complete

FIGURE 10.4. Components of biocapsule including refilling ports used to load cells and recharge system.

NANOPOROUS MICROSYSTEMS FOR ISLET CELL REPLACEMENT |

179 |

medium media is carefully delivered into the capsule through a tuberculin syringe attached to the filling tube. Then the tube and syringe will be removed and the ports are covered with caps (figure 10.4). The alginate is allowed to polymerize overnight in complete media containing CaCl2 (37◦C in humidified 5% CO2). The following day the filled capsule is evaluated in vitro or implanted.

One concern that is often brought up in related to encapsulation technologies has to do with the escape of very small antigenic peptides or the entrance of small inflammatory cytokines from the device, thus leading to an inflammatory response despite protection of the cells from larger antibodies and complement molecules. This issue has been of great interest in the encapsulation community since it brings up serious concerns about the potential value of any immunobarrier regardless of its molecular weight cut-of. The requirements of a membrane for immune protection are related to its diffusive permeability and will be primarily dependent on the donor-host mismatch: allogeneic vs. xenogeneic [61,30]. The indirect pathway, where shed antigens from the graft stimulate system CD4 T-cells, is secondary and less significant for allografts [33]. In either case, however, it is the goal to minimize the contact between the host’s immune cells and any component of the encapsulated cells, because any activation of the local immune cell population may result in the local production of inflammatory cytotoxic agents such as IL-1β, IFNγ, and TNFα. Therefore, we believe that the issue of cell-secreted antigens and cytokines needs to be further investigated in the context of our immunoprotective membranes. We have already used surface modification strategies for our biocapsule which involve chemical vapor deposition of polyethylene glycol to diminish non-specific binding [65]. These membranes have shown to have significantly decreased peptide adsorption and fibroblast adhesion, and may be advantageous in terms of limiting the inflammatory response due to non-specific adhesion of cell-secreted antigens.

10.4. BIOCOMPATIBILITY OF NANOPOROUS MEMBRANES AND BIOCAPSULAR ENVIRONMENT

Early studies showed that silicon microdevices were biocompatible in vitro and in vivo [55]. For these microimplants, there appeared to be no changes in the mechanical properties of the implants and no corrosion was observed. The filtration channels appeared clear and free from any obstructions. No gross abnormalities of color or consistency were observed in the tissue surrounding the implant. No necrosis, calcification, tumorgenesis, or infection was observed at any of the implant sites, suggesting that silicon substrates were well-tolerated and non-toxic both in vitro and in vivo, leading to our further studies on cell encapsulation within biocapsules.

The behavior of different cell types in three-dimensional silicon microstructures was studied using microfabricated half-capsules [10]. All cells had normal growth characteristics, morphology, and greater than 90% viability. Overall, islets in microfabricated silicon pockets and the control dishes appeared to have similar morphology and viability. Glucosesupplemented medium was allowed to diffuse to the islets, from underneath the membrane, to stimulate insulin production and monitor cell functionality. The concentration of insulin, secreted by the islets through the membrane, into the surrounding medium was compared

180 |

TEJAL A. DESAI ET AL. |

150

78 nm

78 nm

free islets

18 nm

18 nm

66 nm

66 nm

100

μIU/ml Insulin

50

0

0 |

10 |

20 |

30 |

40 |

50 |

60 |

Time (minutes)

FIGURE 10.5. Insulin secretory profile through differing pore sizes.

between the unencapsulated islets and the islets on micromachined membranes [11, 14]. The amounts were similar in concentration and time release suggesting that glucose was able to sufficiently pass through the pores of the wafer pockets to stimulate islets for insulin production. Figures 10.5 and 10.6 show the typical insulin release profile in response to stimulatory (16.7 mM) glucose medium over 1 hour under static incubation for 78 nm, 66 nm, and 18 nm pore-sized membranes and in the presence of an alginate matrix within the biocapsule. This profile indicated that insulin and glucose diffusion occurred at sufficiently high rates through the microfabricated membrane to ensure nutrient exchange for encapsulated islet cells. These experiments show that no diffusion barrier is formed by the membrane for glucose and insulin, while taking into account the effect of rotation on mass transfer.

|

700 |

|

|

|

600 |

1.5% alginate |

|

|

|

|

|

hr) |

500 |

.15 % alginate |

|

|

|

||

/ |

|

|

|

/islet |

400 |

|

|

300 |

|

|

|

insulin(pg |

|

|

|

200 |

|

|

|

100 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

1.67mM |

16.7mM |

glucose (mM)

FIGURE 10.6. Glucose stimulation of rat islets in alginate filled biocapsules.

NANOPOROUS MICROSYSTEMS FOR ISLET CELL REPLACEMENT |

181 |

10.5. MICROFABRICATED BIOCAPSULE MEMBRANE DIFFUSION STUDIES

Since biocapsules are diffusion based devices, understanding the diffusion properties of the semipermeable membrane employed is critical to optimizing the passage of relevant biomolecules, and to tailoring immunoisolation capabilities. Commercial polymeric membranes utilized for cell encapsulation purposes have been poorly characterized in terms of large and small molecule diffusion properties. Indeed, it is often complicated to determine the diffusive transport properties of these membranes due to their variability and asymmetry. Typically, they are based on the nominal molecular weight cut off of the membrane, however, the non-uniformity in membrane architectures makes it difficult to define the absolute cut-off dimensions as well as the channel length, pore sizes and distribution. Conversely, microfabrication technology allows to precisely control pore size, pore distribution and diffusion path length. Therefore, due to the uniformity and known geometry of the micromachined membrane, it is much more straightforward to determine important diffusion parameters. Diffusion studies described here focused on the parallel pore design and different pore sizes were taken into consideration. In this case, immunoisolative properties were characterized in addition to glucose and albumin diffusion.

The mass transport properties of an encapsulation membrane are critical since the influx and outflux of relevant molecules will determine the extent of encapsulated cell viability. At the same time, the membrane must be able to provide considerably greater impedance to the diffusive transport of large molecular weight immunomolecules. In addition, when the device functions as an implantable homeostatic sensor-release system, it is fundamental for the entrapped cells to be able to respond promptly to fluctuations in solute concentrations of the interstitial fluid in order to retain a physiologic dynamic response.

Glucose, albumin, and IgG diffusion through parallel pore membranes with 7, 13, 20, and 49 nm was characterized. Because the initial concentrations in compartment A is significantly high, it is reasonable to assume that the donor cell acts as an infinite source and the concentration gradient between the two cells does not change significantly over the course of the experiment. Therefore, the flux across the membrane can be considered in steady state, and zero-order kinetics is expected from such system. Deff was calculated from concentrations experimentally measured. The diffusion coefficients were then normalized by the diffusion coefficient in water, calculated according to the Stokes-Einstein equation.

In the current fabrication protocol, the pore cross-sectional area is a linear function of the pore size, thus Aeff increases linearly with the pore size (Table 10.1). The measured effective diffusion coefficients were all lower than that for free diffusion in water (Table 10.2). For glucose and albumin, the relative diffusivity (Deff/DH2O) values increased with pore size,

TABLE 10.1. Pore size versus pore area.

Pore Size |

Porosity |

Pore Area |

nm |

% |

mm2 |

|

|

|

7 |

0.30 |

0.0208 |

13 |

0.55 |

0.0387 |

20 |

0.85 |

0.0595 |

49 |

2.08 |

0.1458 |

|

|

|

182 TEJAL A. DESAI ET AL.

TABLE 10.2. Measured effective diffusion coefficients.

|

|

Stokes |

|

Deff |

Deff |

Deff |

Deff |

|

MW |

Radius |

DH2O |

7 nm |

13 nm |

20 nm |

49 nm |

Molecule |

Da |

Nm |

cm2/s |

pore size |

pore size |

pore size |

pore size |

Glucose |

180 |

0.37 |

6.14E-06 |

6.34E-07 |

2.06E-06 |

3.20E-06 |

4.24E-06 |

Short-term |

|

|

|

|

|

|

|

Glucose |

180 |

0.37 |

6.14E-06 |

N/A |

1.98E-06 |

N/A |

3.18E-06 |

Long-term |

|

|

|

|

|

|

|

Albumin |

67,000 |

3.55 |

6.40E-07 2.10E-08 1.90E-07 |

3.09E-07 |

4.3E-07 |

||

IgG |

150,000 |

5.90 |

3.85E-07 |

1.33E-10 |

2.19E-10 |

N/A |

2.71E-09 |

|

|

|

|

|

|

|

|

nearing 1.0 for 49 nm pore sizes (Figure 10.7). As the nanopore channel width decreased, approaching several times the molecular dimensions of the solute molecules themselves, the rates of diffusion deviated appreciably from those predicted by Fick’s first law. For example, the diffusion coefficient of glucose measured using a 7 nm nanopore membrane is substantially less than that seen with a 13 nm or 20 nm nanopore membrane (figure 10.8).

These data suggest that at channel widths below about 13 nm, the diffusion of glucose is constrained by the geometry of the nanopore channels, resulting in a slower than expected efflux through the nanopore membrane. A similar phenomenon was seen for a higher molecular weight solute, albumin (MW 67,000 daltons), except the channel widths at which non-Fickian diffusion is seen is in the range below 20 nm. Note that at channel widths below about 7 nm, virtually no efflux of albumin is seen. At a channel width above 20 nm, the measured diffusion constant is about equal to that predicted by Fick’s law. The Stokes radius of albumin determined by gel exclusion chromatography is about 4 nm, suggesting that its molecular diameter is about 8 nm. The lack of albumin diffusion through the nanopore with the 7 nm membrane is understandable, as the channel thickness would physically exclude passage of the molecule.

These data suggest a relationship between the rate of diffusion of molecules through nanopore membranes and the size of the nanopore channels. On one extreme, as expected, if the channel width is below the molecular dimensions of the solute, virtually no diffusion is observed. On the other extreme, for channel widths that are approximately 2–5 fold greater

|

1.0 |

|

|

|

|

|

|

|

|

Glucose |

|

|

|

|

|

|

0.8 |

Albumin |

|

|

|

|

|

Fick |

0.6 |

IgG |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

/D |

|

|

|

|

|

|

|

eff |

0.4 |

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.2 |

|

|

|

|

|

|

|

0.0 |

|

|

|

|

|

|

|

0 |

10 |

20 |

30 |

40 |

50 |

60 |

Pore Size, nm

FIGURE 10.7. Effective diffusion versus molecular size and pore size of the membrane.

NANOPOROUS MICROSYSTEMS FOR ISLET CELL REPLACEMENT |

183 |

Percent Glucose Release

100 |

|

|

|

|

|

|

|

|

80 |

27 nm |

|

|

|

|

|

|

|

|

20 nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

|

|

|

13 nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 nm |

|

|

20 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

Time (Days)

FIGURE 10.8. Diffusion profiles of glucose through Microfabricated membranes. At small pore sizes, molecules exhibit non-Fickian behavior.

in size than molecular dimensions of the solute, Fickian diffusion behavior is observed, that is, the geometry of the nanopore membranes does not constrain diffusion. For channel widths ranging from approximately the molecular dimensions of the solute to severalfold larger than this value, hindered diffusion is observed.

The origin of the constrained diffusion seen for solutes passing through nanopore membrane channels may be somewhat related to the phenomenon of singlefile. Singlefile diffusion is a one-dimensional transport process involving particles that cannot pass each other due to constrained pathways [56–59]. However, in our case, we actually have slit-like diffusion, since our channels are rectangular. Similar effects occur when a colloidal particle is confined in a small gap between two flat walls such as is the case for solute molecules diffusing through nanopore channels [60].

Another possible explanation for the constrained diffusion seen here are drag effects. When a colloidal particle suspended in a quiescent fluid is close to a flat wall, the Stokes drag force acting on it is increased relative to that when far from the wall and, therefore, its diffusion coefficient is smaller than that when far from the wall. The increase of the drag force is attributed to the alteration of the hydrodynamic interaction between the particle and the fluid generated by the boundary condition imposed by the nearby wall.

10.5.1. IgG Diffusion

Our studies have indicated that microfabricated biocapsule membranes can be tailormade to attain desired IgG diffusion kinetics [14, 43]. At the same time, we have shown that the deselection of IgG requires absolute pore dimensions of 13 nm or less (Figure 10.9). This refines the previous understanding that pores in the range 30–50 nm would suffice to provide membrane-based immunoisolation [5]. We found that the percent of IgG diffusion (concentration of IgG that passes through the membrane) was 2% after over 150 hours through the 18 nm membranes and less than 0.001% in 13 nm membranes after 4 days. Compared to commonly used polymeric membranes, this rate was several times smaller