- •1Sp 2 semester Module 1

- •1.1. Shaft Alternators on Board Ships

- •Operating Principle

- •Advantages of the shaft alternator systems

- •Improved availability thanks to fully digitalized control and monitoring system

- •Closed-loop control

- •Advantages of the shaft alternator systems of stn systemtechnik nord

- •2000 KW, 840-1400 rpm shaft alternator on the polar research vessel „Polarstern", driven via the power take-off of a reduction gear

- •1.2. Turbogenerator

- •2.1. Boiler design

- •2.2. Refplant cycle of operation

- •Words to be Learnt

- •2.3. Air compressor

- •1. Personal safety

- •2. About the compressor

- •2.1 Construction

- •2.2 Safety equipment

- •Important: The safety valves, bursting disc and any other safety equipment must be inspected regularly.

- •3. Installation and operation

- •3.1 Installation instructions

- •3.2 Cooling water system

- •3.3 Start-up

- •3.4 Operation

- •3.5 Stopping

- •4. Operational failures

- •5. Inspection and maintenance

- •5.3 Lubrication system

- •5.4 Bearings

- •5.5 Pistons and piston rings

- •5.7 Coolers

- •5.8 Filters

- •2.3. Special purpose plants and machines

- •Tachogenerator Interface Board

- •Ac Drives

- •Transmitter - receiver

- •Differential transmitter - receiver

- •Control transformer

- •Resolver

- •General Description

5.8 Filters

The air filter is cleaned using a high quality degreasing agent. Clean the filter with compressed air and apply a thin layer of compressor oil.

The oil filter should be replaced as a single unit. The recommended replacement interval is every 1000 operating hours.

2.3. Special purpose plants and machines

Tachogenerator is a device which generates an electrical output directly proportional to the shaft speed. The voltage thus generated is fed to a speedometer for speed measurement and/or used as feed - back signal for controlling the speed of a rotating machine / equipment. In every automatic control system, since the system performance is directly related to the performance it becomes essential that the Tachogenerator must satisfy certain minimum requirements such as:

Linear

The rectified output voltage should be strictly linear with respect to the rotational speed

Output signal

The ripple content in the rectified output signal must be as low as possible

Temperature effect

Variations in ambient temperature should have negligible effect on the TG output

Long-term stability

Instability of output cause due to aging of parts, shift in magnetic circuits etc., should be minimum.

Unique features of Tachogenerator

ALINCO permanent magnet in the rotor assembly gives long term stable operation under varying ambient temperature.

Large number of poles (48) results in a high frequency output and hence good dynamic response, linearity and wide speed control, along with low ripple content in the rectified output.

Rotor and stator assemblies are encapsulated with epoxy resin to prevent any ingress of moistures, dust etc.

AC tachogenerators in 24 or 48 pole constructions with quasi-sinusoidal output of 30/ 50 Volts AC (rms) 1500 rpm

Stator assembly is housed in cast iron body to minimize magnetic interaction and consequent losses.

Grease filled, double shielded ball bearings are used for maintenance free operation.

Two mounting options-foot mounted and flange mounted.

Speedometer can be calibrated to suit the customer's requirements.

Compact and rugged construction provides longer life with excellent performance even under severe environments.

If required, TG can be supplied with rectifier unit, for DC operations.

Technical Specification

Type -Totally enclosed

Class of insulation -B

Voltage -30V / 50V AC and frequency 600Hz at 1500 rpm

Max. Load Resistance at Output - 600 Ω

No. Of poles - 48

Linearity - 0.5%

TACHOGENERATOR INTERFACE BOARD

Tachogenerator Interface Board

This is a small, inexpensive interface board that fits in the (optional) expansion connector of either Pro-120, VTX or earlier NCC controllers and is used with a tachogenerator to sense true motor speed to use in a closed loop control system.

It was originally developed for Dutch distributor - where it is used in an agricultural seedling planter - the space between the plantlets must be carefully controlled, hence the use of a tachogenerator to accurately control the speed of the machine.

The board should be ideal for most Robot Wars contestants: fitting tachogenerator feedback rectifies most of their known problems, including motor matching (inability to steer straight) and a tendency to bounce when load changes suddenly. However - the system will require setting up as a system, so does require some understanding.

The board available is physically matched to the Pro and NCC series controllers, but it is also a useful addition to other controllers.

Two versions of the board exist: one has a 9 way connector for the Pro series, the other has a 6 way, for the NCC series controllers. Note that the NCC tacho board will work electically with the VTX but is too large to fit into the boxed VTX.

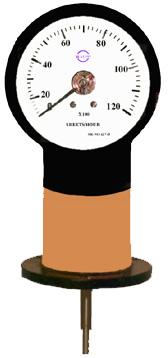

DESCRIPTION: Model AT-4 V is combination of Tachogenerator and indicator in one piece for direct mounting on machines. The indicator is mounted on the tachogenerator through a suitable rubber mount so that machine vibration are not transmitted to the movement of the indicator. Tachogenerator front part can be made specially to suit replacement of imported speed indicators.

APPLICATIONS:

Direct mounting type speed indicator.

Local Indicator.

On the JT8D engine the inlet gearbox drives the N1 tachogenerator.