02 BOPs / Woods D.R 2008 rules-of-thumb-in-Engineering-practice (epdf.tips)

.pdf

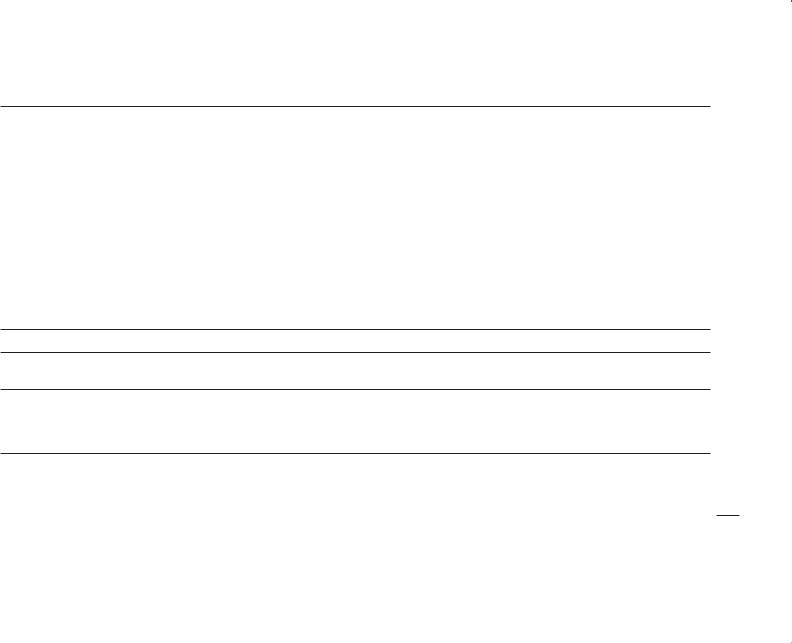

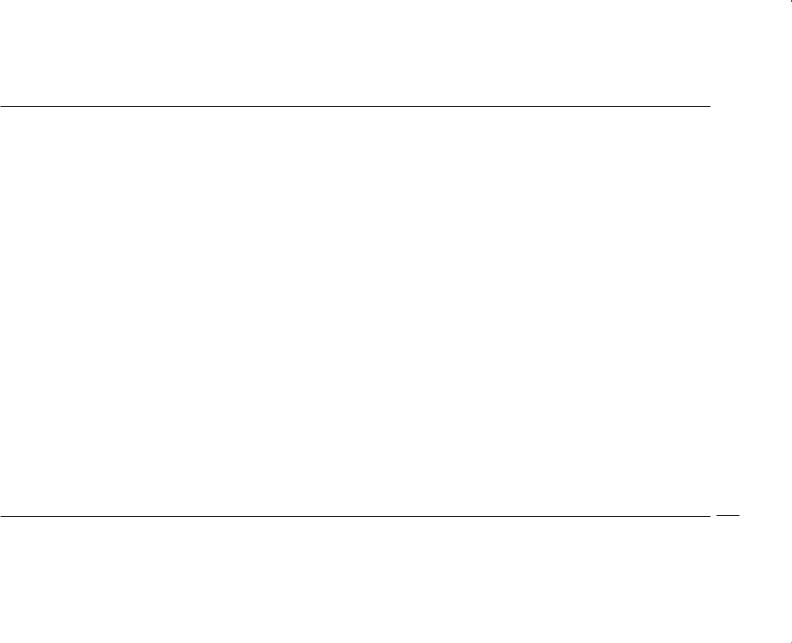

Table 6.8 Continued.

Type of reaction |

Example |

Products/ |

Temperature, hC |

Catalyst life |

Cause of decay |

Max. temp., hC |

Comments about |

|

catalysts |

reactants |

|

|

|

|

regeneration |

|

|

|

|

|

|

|

|

Amination |

Ni, |

|

|

|

|

|

|

via reduction |

Cu & Cr oxides |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ammoxidation |

Pt Pt–Ru |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mixed oxides, |

acrylonitrile |

220 |

1–3 years |

|

|

|

|

Fe, Sb, Sn |

ex ammonia, pro- |

|

|

|

|

|

|

|

pylene |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mixed metal |

acrylonitrile |

450 |

1–3 years |

volatalization, |

|

periodic addition |

|

molybdates or |

ex propene |

|

|

attrition |

|

of Mo ammo- |

|

antimonates |

|

|

|

|

|

nium salt as |

|

|

|

|

|

|

|

vapor |

none

Carbonylation, homogeneous hydroformylation, FT

Ni or Pd on C or Co Rh or Ni carbonyl or Fe carbonyl

|

Cu |

methanol |

200–300 |

2–8 years |

slow sintering, |

325 |

|

|

|

|

|

poisons |

|

|

|

|

|

|

|

|

Chlorination |

none |

|

|

|

|

|

|

|

|

|

|

|

|

|

ferric chloride |

|

|

|

|

|

|

|

|

|

|

|

|

201 Guideline General 2.6

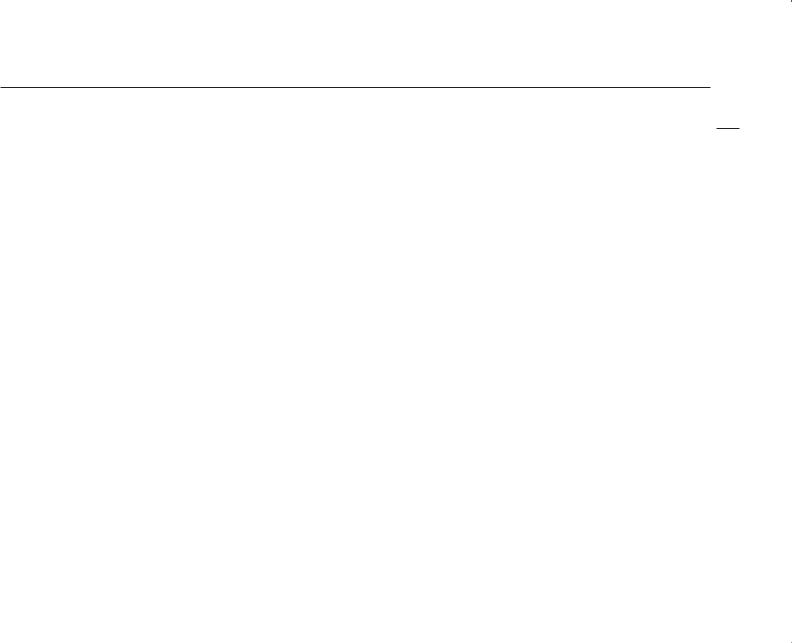

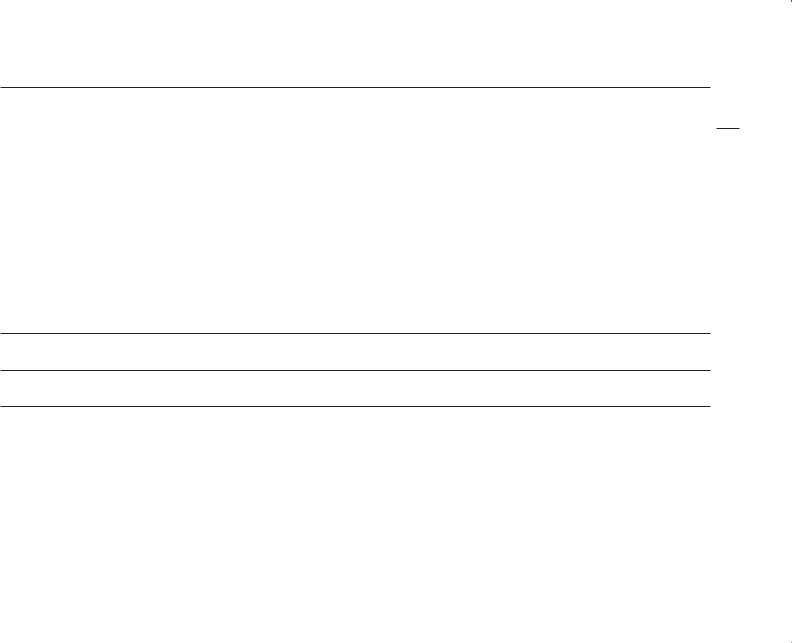

Table 6.8 Continued.

Type of reaction |

Example |

Products/ |

Temperature, hC |

Catalyst life |

Cause of decay |

Max. temp., hC |

Comments about |

|

catalysts |

reactants |

|

|

|

|

regeneration |

|

|

|

|

|

|

|

|

Condensation |

Fe/alumina |

ammonia ex hy- |

450–470 |

10–15 years |

slow sintering, |

625 |

|

|

[K2 O] |

drogen, nitrogen |

|

|

poisons |

|

|

|

|

|

|

|

|

|

|

|

Rh/Ba/MgO or |

|

|

|

|

|

|

|

iron oxide or alkali |

|

|

|

|

|

|

|

earths or homoge- |

|

|

|

|

|

|

|

neous |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cracking, cat |

Co/Mo S or Si |

|

|

|

|

|

|

|

alumina or Pd or |

|

|

|

|

|

|

|

oxides of V, Mn, Fe, |

|

|

|

|

|

|

|

Cu, Mo, W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

zeolite |

refinery oils |

500–560 |

1–2 s |

rapid coking, |

595 |

regenerate con- |

|

|

|

|

|

poisons |

|

tinuously in sepa- |

|

|

|

|

|

|

|

rate fluidized bed |

|

|

|

|

|

|

|

|

Dehydration |

Ta silica |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dehydrochlorination |

none |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

silica alumina or |

|

|

|

|

|

|

|

NaOH or metal |

|

|

|

|

|

|

|

chloride |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dehydrogenation |

none |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cu–Cr; Cu–Zn– |

2 butanone |

|

2 years |

|

|

regenerate every |

|

bronze |

|

|

|

|

|

2–3 months |

|

|

|

|

|

|

|

|

|

Ni or Pt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

oxides of Cr, |

butadiene ex bu- |

600–680 |

i 0.5 year |

|

|

regenerate for 1 h |

|

Ni, Fe |

tene or butane |

|

|

|

|

every 1–7 days |

|

|

|

|

|

|

|

|

Reactors 6 202

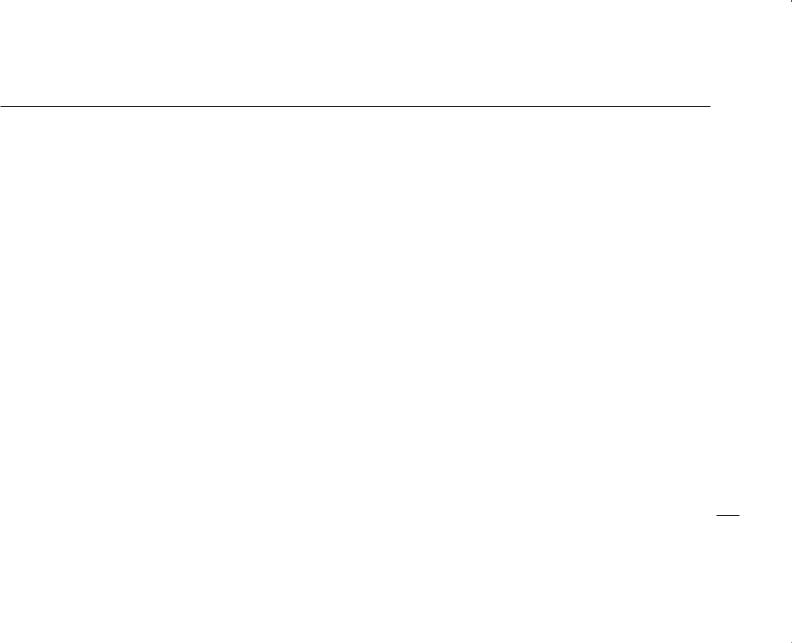

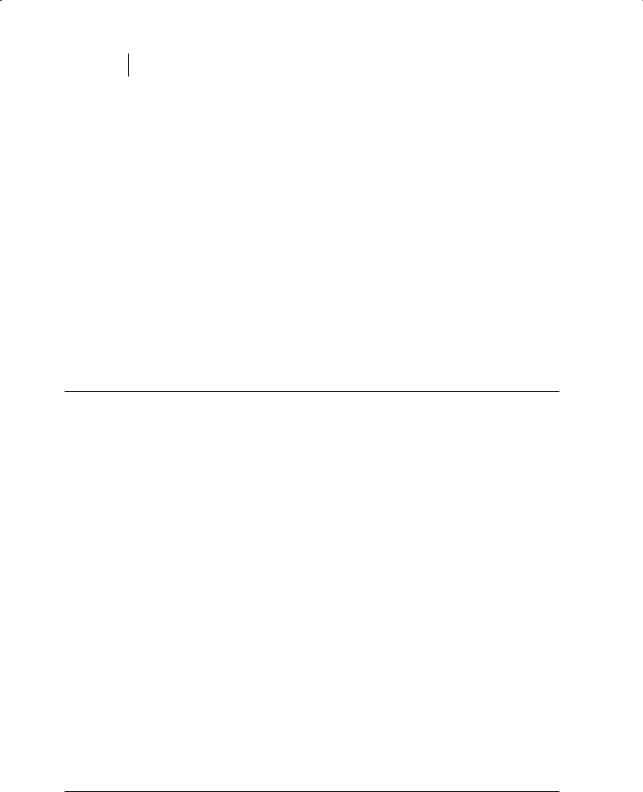

Table 6.8 Continued.

Type of reaction |

Example |

Products/ |

Temperature, hC Catalyst life |

Cause of decay |

Max. temp., hC |

Comments about |

|

catalysts |

reactants |

|

|

|

regeneration |

|

|

|

|

|

|

|

Dimerization |

tripropylalumi- |

|

|

|

|

|

|

num |

|

|

|

|

|

|

|

|

|

|

|

|

Disproportionation |

CdI or zeolite |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rh/alumina |

propylene from |

50 |

|

|

regenerate every |

|

|

ethylene |

|

|

|

10 days |

|

|

|

|

|

|

|

Epoxidation |

homogeneous |

|

|

|

|

|

|

|

|

|

|

|

|

Esterification |

IX resin or |

|

|

|

|

|

|

sulfuric acid |

|

|

|

|

|

|

|

|

|

|

|

|

Ethynylation |

Cu acetylide or |

|

|

|

|

|

|

KOH |

|

|

|

|

|

|

|

|

|

|

|

|

FT |

Ni or Cu with |

|

|

|

|

|

|

ZnO or carbides of |

|

|

|

|

|

|

Fe, Mo, W |

|

|

|

|

|

|

|

|

|

|

|

|

|

Co/ZrO2/SiO2 |

alcohols |

5 years |

|

|

regen. once per |

|

|

|

|

|

|

year. |

|

|

|

|

|

|

|

Halogenation |

none |

|

|

|

|

|

|

|

|

|

|

|

|

Hydration |

homogeneous |

|

|

|

|

|

|

cupric chloride |

|

|

|

|

|

|

|

|

|

|

|

|

|

sulfuric or |

|

|

|

|

|

|

phosphoric acid or |

|

|

|

|

|

|

Ta on silica |

|

|

|

|

|

|

|

|

|

|

|

|

203 Guideline General 2.6

Table 6.8 Continued.

Type of reaction |

Example |

Products/ |

Temperature, hC |

Catalyst life |

Cause of decay |

Max. temp., hC |

Comments about |

|

catalysts |

reactants |

|

|

|

|

regeneration |

|

|

|

|

|

|

|

|

Hydrodealkylation |

none |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cr or Mo oxides or |

|

|

|

|

|

|

|

Pt on zeolites |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydroformylation |

Co or Ru or Rh or |

|

|

|

|

|

|

|

Co or Pd on C or |

|

|

|

|

|

|

|

Cu, Ni, Zn or Fe |

|

|

|

|

|

|

|

pentcarbonyl |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydrogenation |

Pt or Cu on Si or |

|

|

|

|

|

|

|

Ni Cr or Pd on C or |

|

|

|

|

|

|

|

Raney Ni or Pt-Co/ |

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cu on ZnO |

alcohols ex |

220–270 |

0.5–1 year |

slow sinter |

|

|

|

|

aldehydes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cu-Cr oxides |

furfuryl alcohol |

150–200 |

|

coke |

|

regenerate with |

|

|

ex furfural |

|

|

|

|

oxidation |

|

|

|

|

|

|

|

|

|

CuO/ ZnO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sulfided Ni |

aniline ex |

300–475 |

|

coke |

|

decoke via air |

|

|

nitrobenzene |

|

|

|

|

burn at 300 with |

|

|

|

|

|

|

|

later reduction via |

|

|

|

|

|

|

|

hydrogen |

carbides of Fe, Mo, W on alumina

Reactors 6 204

Table 6.8 Continued.

Type of reaction |

Example |

Products/ |

Temperature, hC |

Catalyst life |

Cause of decay |

Max. temp., hC |

Comments about |

|

catalysts |

reactants |

|

|

|

|

regeneration |

|

|

|

|

|

|

|

|

Hydrolysis |

sulfuric acid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pd or Co Mo |

|

|

|

|

|

|

Hydrotreat |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sulfided |

light distillate |

300 |

10 year |

poisons V, Ni, |

450 |

regenerate in situ |

|

Co–Mo/g- |

|

|

|

Fe; coke |

|

by burning coke |

|

alumina |

|

|

|

|

|

about 2 times via |

|

[Bo, P, K, SiO2] |

|

|

|

|

|

combustion with |

|

|

|

|

|

|

|

steam–air. For |

|

|

|

|

|

|

|

poisoning, regen. |

|

|

|

|

|

|

|

externally with |

|

|

|

|

|

|

|

aqueous leach |

|

|

|

|

|

|

|

|

|

sulfided Ni |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Isomerization |

zeolites |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pt |

xylenes ex ethyl |

400–480 |

3–5 years |

|

|

regenerate every |

|

|

benzene |

|

|

|

|

6–18 months |

|

|

|

|

|

|

|

|

|

oxides of V, Mn, Fe, |

|

|

|

|

|

|

|

Cu, Mo, W or oxi- |

|

|

|

|

|

|

|

des of rare earths |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nitration |

Co naphthaneate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mixed acids |

|

|

|

|

|

|

Guideline General 2.6

205

Table 6.8 Continued.

Type of reaction |

Example |

Products/ |

Temperature, hC |

Catalyst life |

Cause of decay |

Max. temp., hC |

Comments about |

|

catalysts |

reactants |

|

|

|

|

regeneration |

|

|

|

|

|

|

|

|

Oxidation |

Cu Ag or Fe Mo |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ag/a-alumina |

ethylene oxide |

200–270 |

1–3 years |

poisons, Cl and S; |

|

regen. via peri- |

|

[alkali metals] |

ex ethylene, air |

|

|

some coking |

|

odic addition of |

|

|

|

|

|

|

|

Cs/methanol |

|

|

|

|

|

|

|

solution |

|

|

|

|

|

|

|

|

|

Pt Rh gauze |

NO ex ammonia |

800–900 |

0.1–0.5 years |

loss of Pt, fouling |

|

|

|

|

|

|

|

|

|

|

|

Pd Cd/alumina |

vinyl acetate ex |

140–180 |

2 years |

sintering |

|

|

|

|

ethylene, acetic |

|

|

|

|

|

|

|

acid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V/K sulfate |

sulfur trioxide |

525 |

5–10 years |

plugging, sintering |

|

|

|

|

ex sulfur dioxide |

|

|

|

|

|

mixed oxides; metallic oxides or AgO

homogeneous: Mn, Cu or Co acetate

Reforming |

zeolite |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

metals, Ni/ |

steam reform |

500–850 |

2–4 years |

sintering, coke, |

875 |

|

|

alumina |

ex methane |

|

|

sulfur poison |

|

|

|

|

|

|

|

|

|

|

|

Pt/treated |

|

460–525 |

0.01–0.5 years |

coking |

550 |

frequent regen- |

|

alumina |

|

|

|

|

|

eration needed |

|

|

|

|

|

|

|

|

Reactors 6 206

|

|

6.2 General Guideline |

207 |

|

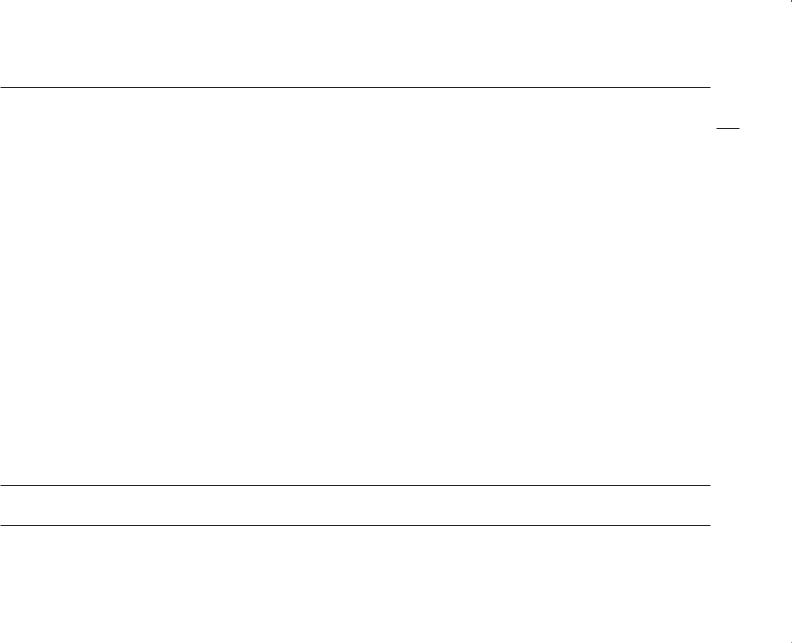

Table 6.9 How the solid catalyst affects choice of reactor. |

|

|

|

|

|

|

|

||

|

|

|

|

|

Conditions |

Consider the following |

Constraints |

||

|

type of reactor |

|

|

|

|

|

|

|

|

Catalyst retains activity |

fixed bed |

if I 3 months use fluidized, |

||

i 3 months: |

|

moving, or slurry |

||

Operating pressure high |

fixed bed |

if catalyst strength |

||

|

|

i 3 kg/ particle |

||

Reaction is highly exothermic |

fluidized bed |

if the attrition I 1 %/day |

||

Very short contact time |

monolith with low pressure |

|

|

|

available |

drop or fluidized/loop |

|

|

|

|

reactors with recycle |

|

|

|

Enzyme catalyst |

fixed bed |

if immobilized |

||

|

CSTR |

if pH and temperature control |

||

|

|

are vital or if mass transfer |

||

|

|

controls |

||

|

|

|

|

|

6.2.4

Specific Guidelines for Gases Reacting with Solid

When the solid reacts with gas, usually heat transfer controls because these are highly exothermic or endothermic reactions. Particle size and size distribution are critical. These reactions may follow different patterns:

xfor multigranule reactions the time for reaction = independent of particle diameter.

xfor shrinking core without ash reactions, the time for reaction

/particle diameter (for reaction controlled), / D1.5 (for fluid diffusion controlled with fluidized, fixed or moving beds),

/D2 (for fluid diffusion controlled with transported bed)

xfor shrinking core plus ash, the time for reaction / Dp

(for reaction controlled), / Dp (for fluid diffusion controlled),

/Dp2 (for fluid diffusion through the ash controlled).

6.2.5

Bioreactors

The two general types of bioreactors are anaerobic and aerobic: anaerobic means no oxygen is present; aerobic means oxygen must be supplied with 17 kJ of heat released/g O2 utilized = 13 kJ/g of cell mass generated.

The three types of biotechnical products are:

1.cell biomass

2.metabolic products of cells: anaerobic: alcohols, organic acids, hydrogen, carbon dioxide; for aerobic: citrate, gluta-

208 6 Reactors

mate, lactate, antibiotics, hydrocarbons and polysaccharides, yeast and single cell protein SCP

3. enzymes that can be used as catalysts.

In selecting an aerobic bioreactor, there is a tradeoff between the degree of mixing and the required rate of oxygen transfer, OTR. How this affects the type of reactor is illustrated in Table 6.10.

Some useful definitions are:

microorganism: microscopic, living organisms including prokaryotes (e.g. bacteria) and eukaryotes (fungi).

bacteria: microorganisms that are cells without a fully differentiated nucleus. May be round, rod-like, spiral or filamentous of diameter 0.5–3 mm.

fungi: microorganisms that are cells with membranes with a discrete nuclei (eukaryotes). They are saprophytic and parasitic plants that lack chlorophyll. Fungi are typically filaments that are 5-15 mm diameter and 50–500 mm long.

Table 6.10 Some bioreactions with different types of microorganisms.

Factors related to the reactor |

Microorganisms |

|

|

|

|

Bacteria |

Fungi |

|

Mixed culture |

|

|

yeasts |

fungi, moulds |

|

|

|

|

|

|

Amount of biomass, kg/m3 |

10–50 (0.001–0.01) |

10–50 |

10–50 |

5 |

(volume fraction) |

|

|

|

|

Biomass viscosity, mPa s |

low, I 100 |

low, I 100 |

high, 100–1500 |

low, I 100 |

Oxygen consumption, g/s m3 |

0.2–1 |

0.2–1 |

0.2–1 |

0.002–0.01 |

kLa, gas–liquid, 1/s |

0.05–0.2 |

0.05–0.2 |

0.01 |

0.003 |

kLa, liquid–solid, 1/s |

0.01–0.5 |

0.25 bubble |

0.1–1 jet loop |

|

Metabolic heat production, |

3–15 |

3–15 |

3–15 |

0.03–0.14 |

kW/m3 |

|

|

|

|

Sensitivity to shear |

relatively insensi- |

sensitive (animal and plant cells) |

fluidized |

|

|

tive, robust |

|

|

|

Choice of reactor configuration |

aerated STR; |

bubble reactors: jet loop or air lift |

fluidized |

|

if fermentation requires high |

0.1–1.7 kW/m3 |

|

|

|

OTR; e.g. antibiotics, acetic |

|

|

|

|

acid, SCP |

|

|

|

|

Choice of reactor configuration |

aerated STR; |

packed column, immersed wick, |

|

|

if fermentation requires low |

0.1–1.7 kW/m3 |

immersed column |

|

|

OTR; |

|

|

|

|

Example rate of growth of |

1–2.5 |

0.5–1.2 |

0.3–0.5 |

|

biomass for the production |

|

|

|

|

of Single cell protein, SCP, g/s m3 of broth

6.2 General Guideline 209

yeast: a fungus of the family Saccharomycetacea that is typically 1–50 mm in diameter.

enzyme: a protein produced by living cells that catalyzes the metabolic process. For mixed culture microorganisms used for biological treatment of waste water, the general range of values used are: BODu z 1.43 q BOD5; Approximately

1.4–1.5 kg O2/kg BOD5.

Microorganisms use the organic substrate, characterized by BOD5 or COD, for growth and for endogenous respiration. Illustrative reaction rate terms include, for COD at 20 hC:

Substrate concentration at which the specific growth rate is 0.5 maximum, Ks, = 25–100 mg COD/L.

Maximum specific utilization rate of the substrate, k, = 6–8 kg COD/day kg VSS.

Biomass lost to endogenous respiration per unit time per unit biomass, Kd, = 0.05–0.1 1/day.

Yield of biomass produced per unit of substrate removed, YT, = 0.35–0.45 mg VSS/mg COD.

6.2.6

Reactors for Supercritical Conditions

When a fluid is compressed and heated above the critical conditions (or to supercritical conditions, sc), the differences between gas and liquid disappear. For carbon dioxide, this occurs for temperatures above 31 hC and pressures above 7.3 MPa. For reactions (such as alkylations, aminations, hydroformylations, hydrogenations and Fischer Tropsch synthesis) occurring in supercritical fluids, the reaction rate is often increased dramatically because of improved desorption of heavy molecules; minimizing the oxygen and hydrogen solubility limitations, improved heat transfer, and improved selectivity by a catalyst by minimizing pore diffusion limitations.

6.2.7

Reactors for Polymerization

The options for polymerization reactions, the types of polymerizations and the reactor configurations are given in Table 6.11.

For suspension or emulsion polymerization, the shaft power can be estimated as follows:

Shaft kW = 16 (Di/107)(N/170)3 n where

N = rpm

n = number of impellers on the shaft. Di = diameter of impeller in cm Motor kW = 1.3 q shaft kW

2106 Reactors

Table 6.11 Polymerization reactions.

Liquid phase reactors |

Types of polymerizations |

Reactor options |

|

|

|

1. Bulk: liquid monomer with |

condensations, LDPE, PS, |

STR (3–6 kW/m3 mixer; tip |

initiator in absence of diluent |

Nylon, PMMA, acrylics, |

velocity 0.2–0.3 m/s), long |

or solvent. |

polyacetals |

tubular reactors, screw extru- |

|

|

ders |

2. Solution: monomer dispersed in solvent with soluble catalyst

free radical, ionic, Zeigler Nichols; thermosets, acrylics, PVAlc, PVC, polybutadiene, polypropylene, melamine phenolic resins, polyisoprene, polycarbonate, chlorinated polyesters

glass or s/s STR (2–8 kW/m3 mixer; heat transfer area = 1–4 m2/m3 depending on the volume of the reactor with small area associated with large volumes).

3.Suspension with large drops 10–1000 mm of insoluble monomer and catalyst suspended in water.

4.Emulsion: small drops 0.5–10 mm of insoluble monomer suspended in water with water-soluble catalysts in micelles

Gas phase reactors

free radical addition, styrenic IX resins, vinyl polymers, PVC, styrene-acrylo- nitrile, polypropylene

industrial polymers, synthetic rubbers, polybutadience, PVC, latex paints, adhesives, coatings, ABS, PV acetate, styrene butadiene

batch STR (1–6 kW/m3 mixer; tip speed 6–9 m/s; 3-retreated blades at 46–120 rpm; heat transfer area = 1–4 m2/m3 depending on the volume of the reactor with small area associated with large volumes); continuous PVC

batch STR; 2–3 kW/m3 mixing @ 155–230 rpm; shear number 9000–12 000; impeller diam./tank diam. = 0.25–0.3, U = 110 W/m2 K; heat transfer area = 3.3 m2/m3.

Gaseous monomers, |

heterogeneous solid cat. |

fluidized beds; horizontal with |

continuous |

PE, PP; |

weirs & rotating paddles; |

|

|

helically stirred tanks. |

|

|

|

Since polymerizations are exothermic, it is essential that the heat of reaction is removed. Since polymer and scale tend to build up on any heat exchange surfaces contacting the reactants the preference is to have jacketed reactors. The amount of internal surface area varies from 4 m2/m3 for 1 m3 vessels and reduces to 1.5 m2/m3 for a 35 m3 volume reactor. Cooling fingers or external coolers can be used. The overall heat transfer coefficients are in the range 60–350 W/m2 K. In general, to account for the fouling on the walls, the internal heat transfer coefficient for polymerization reactions is about half that expected.