2015ARKH-P5-Field Development Evaluation(80s)

.pdf

PROJECT SANCTION :

KEY CHALLENGES

Geosciences aspects: Reservoir development plan, development phasing, possible upsides, reserves booking, reserves certification,

Technical: Production facilities selection, expected plant performances, site study, access to site, logistics, project schedule, innovations, use of associated gas…

Environmental: Environmental Baseline Study (EBS) & Environmental Impact Assessment (EIA), access to site, existing facilities or fabrication yards in the area,

Economics: cost estimate, OPEX, CAPEX, cost reduction analysis, market conditions, NPV (Net Present value), IRR (Internal Rate of

Return)…

Financing scheme: Project financing, banks loans, Partners financing, Credit Export Agencies loans..;

PROJECT SANCTION :

KEY CHALLENGES

Contractual: Contractual strategy selection, Local content, insurance scheme, constrained timing,

Legal: Taxation scheme, applicable laws and regulations, land acquisition or lease…

Social: Economical & social impact study, Local manpower availability, training programs,

Risk management: Risks analysis, market evolution, currency fluctuation, suppliers and contractor track records, security aspects…

PROJECT SANCTION :

KEY CHALLENGES

Host Government contract requirements

Fiscal terms

Associate gas requirements/flaring

Local content requirements Local market and skills

Training requirements:

Host country potential challenges

Local currency fluctuation

Local PIB growth

Security aspects

PROJECT SANCTION CHALLENGES:

KEY CRITERIA: PROJECT ECONOMICS EVALUATION

SANCTION PACKAGE is FORMALISED:

To have the monetary value of a project & to analyse the project value drivers (partners may have different target for Project IRR)

To compare technical alternatives

To forecast cashflows and to prepare budgets

To track on going project performances versus budget and forecast

To evaluate tenders and to prepare negotiation positions

Risks & sensitivities analysis

Risk analysis is performed to assess the impact of:

|

Reservoir uncertainties Reserves ? |

||

|

Tight market |

Costs ? Added value ? |

|

|

New technology |

Costs ? Added value ? |

|

|

‘’ |

‘’ |

Schedule? Production delay ? |

|

Lower oil/gas prices |

Project revenue |

|

64

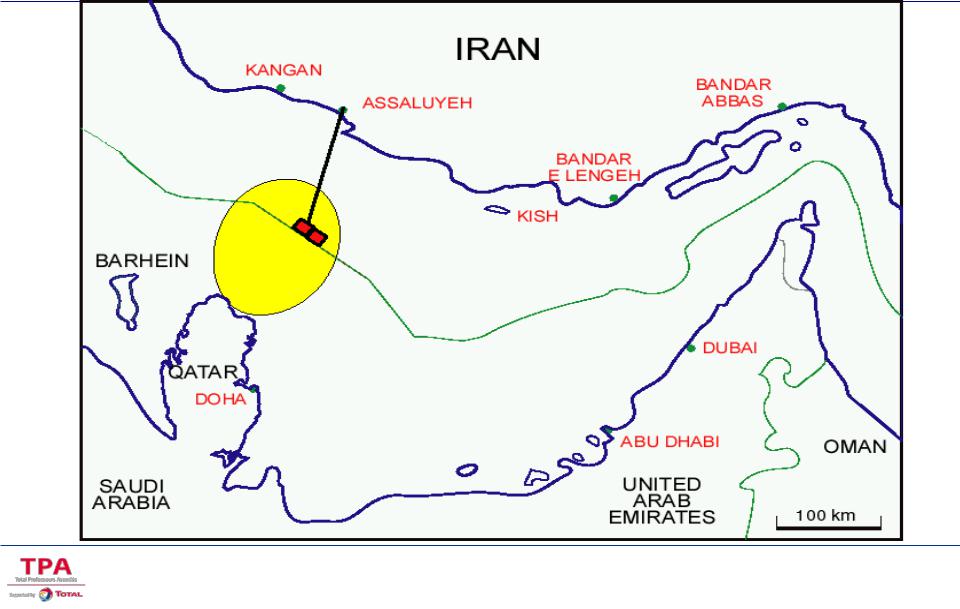

FIELD EVALUATION PROCESS – EXAMPLE

SOUTH PARS 2 & 3 DEVELOPMENT

CONCEPTUAL STUDIES: SOUTH PARS 2&3 PROJECT (1)

66

CONCEPTUAL STUDIES: SOUTH PARS 2&3 PROJECT (2)

SOUTH PARS (Iran) and NORTH FIELD (Qatar) are the largest nonassociated gas field in the world

• SOUTH PARS characteristics |

|

|

- Area |

3,700 SQ KM |

|

- |

Gas in place |

460 TCF |

- |

Condensate in place |

17,100 MMBbl |

• Phases 2 & 3 characteristics |

|

|

- |

Gas Production |

2,000 MMSCFD |

- |

Condensate Production |

77,000 Bbl/d |

- |

Sulphur Production |

500 t/d |

67

CONCEPTUAL STUDIES: SOUTH PARS 2&3 PROJECT (3)

North Field general map |

South Pars 2&3 wet scheme |

|

RAS LAFFAN

1 BScfd |

1 BScfd |

|

0.9 BScfd

Qatargas I « dry scheme »

CONCEPTUAL STUDIES: SOUTH PARS 2&3 PROJECT (4)

General Principle

All possible technical solutions are envisaged

Best development scheme is selected

South Pars

Fluid transfer system from offshore: Mono phase or multiphase flow ?

Wet or Dry?

Constraints:

Viscosity

Pipe Corrosion due to the water Pipe length: 105 km

Studies result:

The multiphase WET scheme cost is lower (30% of Surface Facilities costs savings)

CONCEPTUAL STUDIES: SOUTH PARS 2&3 PROJECT (5)

COMMON FACILITIES: (DEVELOPED BY NIOC)

56” EXPORT LINE

SULPHUR HARBOUR CONDENSATE EXPORT SYSTEM

|

|

ONSHORE GAS TREATMENT PLANT |

|

|

|

|

||

|

|

GAS LIQUID SEPARATION |

|

|

|

|

||

|

|

4 PROCESS TRAIN |

|

|

|

2 SUB SEA PIPELINES |

||

|

|

2 BSCFD PROCESSING CAPACITY |

|

|

|

|||

|

|

|

|

|

32” AND 104 KM LONG |

|||

|

|

77,000 b/d CONDENSATE |

|

|

|

|||

|

|

|

|

|

WET SCHEME FOR RAW GAS |

|||

|

|

500 t/d SULPHUR |

|

|

|

|||

2 OFFSHORE PLATFORMS : |

|

|

|

|

TRANSPORTATION |

|||

|

|

|

|

|

|

|

||

70 M. WATER DEPTH |

|

|

|

|

|

|

|

41/2” PIGGY BACK LINE FOR MEG |

NOT NORMALLY MANNED |

|

|

|

|

|

|

|

TRANSPORTATION |

|

|

|

|

|

|

|

MEG INJECTION OFFSHORE FOR |

|

REMOTE FLARES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CORROSION CONTROL |

|

10 DEVELOPMENT WELLS EACH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPD3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPD4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|