Scheer Solar Economy Renewable Energy for a Sustainable Global Future (Earthscan, 2005)

.pdf

|

|

|

|

|

|

|

Cracking and reformation |

|

Greenhouse effect, damage to |

|

||||||

|

|

|

|

|

Removal of order |

No longer a natural material |

|

|

ozone layer |

|

||||||

|

|

Radical |

|

|

|

|

|

|

|

|

Open loop |

|

||||

|

|

|

|

Eg test petrol, with aromatics removed |

|

|||||||||||

|

|

molecular |

Heat energy for |

|

Decomposition products |

|

||||||||||

|

|

|

|

|

|

|

|

|

||||||||

|

|

restructuring |

cracking, catalysts |

Radical chemical |

|

|

Accidents |

(CHCs, HCI, CO2, NH3, H2O) |

|

|||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

Extraction of |

transformation |

|

Emissions |

|

|

|

|

|

|||

|

Purified fractions |

|

sulphur |

|

|

|

Hazardous waste |

|

UV, water |

Primary emissions |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

(solvents and |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

and soil |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

chemically |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

micro-organisms |

active substances) |

|

||

|

|

|

|

|

Heat energy for |

Organic precursor chemicals |

|

|

||||||||

|

Fractions |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

fractional distillation |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Eg methyl isocyanate (Bhopal), trichlorophenol |

|

User/consumer |

|

|

|||||

|

|

|

|

|

Fire hazard |

(Seveso) etc. Large numbers of highly toxic, |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||||

|

Refinery |

|

Ground water |

carcinogenic, mutagenic compounds |

|

|

|

|

|

|||||||

|

|

|

|

|

CH4 emissions |

Chemical |

|

|

Many accidents, |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Oil |

Detergents (2 million kg/yr) |

synthesis with |

|

|

hazardous waste, |

|

|

|

|

|

||||

|

|

|

emissions to air |

|

|

|

|

|

||||||||

|

|

slicks |

(3 x 1016 litres of water |

innumerable |

|

|

Wood preservatives |

|

|

|||||||

|

|

|

|

|

polluted every year!) |

reactions |

|

|

and water |

|

|

|

||||

|

|

|

|

|

|

|

|

|

dyes and varnishes |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Unrefined oil |

|

Demulsifiers |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Drilling muds, |

Artificial resins |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

Synthetic waxes |

|

|

|

|

|

|

|

||||

|

Crude oil |

|

|

|

|

|

|

|

|

|||||||

|

|

surfactants, |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

antifoaming agents etc |

|

|

|

|

|

|

|

|

|

|

|

|

|

Decay |

Additives, softeners, emulsifiers, |

|

|

Processing plant |

|

|

||||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

3 million years to produce, |

surfactants, algicides, fungicides, |

|

|

|

|

|

|

||||

|

Living organisms |

|

1 year to consume |

bactericides, insecticides |

|

More waste and |

Additives |

|

||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

emissions |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transport (hazardous substance) |

|

|

|

||||||

|

|

|

Comparable structure and energy level |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Source: Hermann Fischer, Plädoyer für eine sanfte Chemie (The Case for Soft Chemistry)6

HAINSC UPPLYS OSSILF THE OFF HROWINGT 212

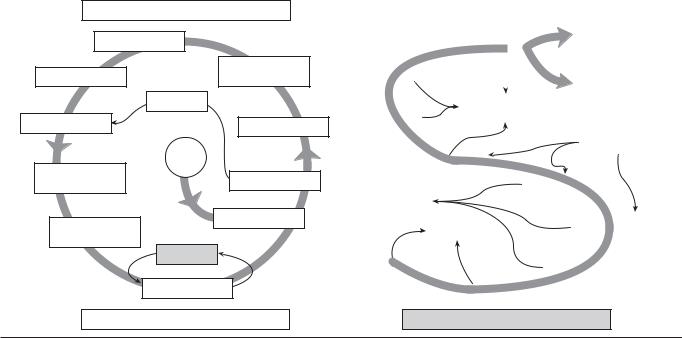

Figure 7.1 The ‘petrochemical snake’

Plant chemistry: closed loop |

|

Natural product |

|

Application |

Intermediate |

product |

|

Oxygen |

|

Micro-organisms |

‘Solar’ material |

|

|

Solar |

|

energy |

|

Biological |

Photosynthesis |

synthesis |

|

Carbon dioxide, |

Plant leaves |

|

|

water |

|

Minerals |

|

Living plants

Solar materials in transparent circular flow

|

|

|

|

|

|

|

|

Petrochemistry: open loop |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Persistent residues |

|||

|

|

|

|

|

|

|

|

|

|

|

Partial |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

decomposition |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Application |

|

|

|

|

|

|

|

|

|

|

|

|

Decomposition |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

products |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Emissions, |

|

|

|

|

|

|

|

||||||

Finished product |

|

|

pollution, waste |

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Higher energy cost |

|||

|

|

|

Intermediate |

|

|

|

|

|

|

|

|

(coal, oil, nuclear) |

||||||||||

|

|

|

|

products |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Precursor chemicals |

|

|

||||||

Numerous byand |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

waste products |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Intermediate |

|

||

|

|

|

|

|

|

|

Oil slicks |

|

|

|

|

|

products |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Crude oil |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Refinery |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Tanker |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Or one-way street?

Source: Hermann Fischer, Plädoyer für eine sanfte Chemie (The Case for Soft Chemistry)7

Figure 7.2 Comparison of solar and petrochemical resources

213 ESOURCESR OLARS OF EALTHW NTAPPEDU HET

214 THROWING OFF THE FOSSIL SUPPLY CHAINS

Table 7.1 Comparison of market prices for fossil and regenerable resources

|

Fossil |

€/t |

($/t) |

Regenerable |

€/t |

($/t) |

|

|

|

|

|

|

|

Raw materials Crude oil |

112 |

(99) |

Maize |

77 |

(68) |

|

|

Natural gas |

171 |

(152) |

Wheat |

99 |

(88) |

|

Naphtha |

137 |

(121) |

Soya |

214 |

(190) |

Precursor |

Benzole |

248 |

(220) |

Rape seed oil |

445 |

(395) |

chemicals |

Ethylene |

332 |

(295) |

Palm oil |

317 |

(282) |

|

Propylene |

245 |

(218) |

Molasses |

133 |

(118) |

|

Methanol |

97 |

(86) |

Sugar |

399 |

(355) |

|

Ammonia |

91 |

(80) |

Starch |

274 |

(243) |

Intermediate |

Ethylene oxide |

511 |

(454) |

Sorbitol |

640 |

(569) |

products |

Propylene oxide |

921 |

(818) |

Glycerine |

1023 |

(909) |

|

Acrylic acid |

1100 |

(977) |

Citric acid |

1023 |

(909) |

|

|

|

|

|

|

|

Source: KATALYSE Institut: Leitfaden Nachwachsende Rohstoffe (Handbook of

Renewable Resources)8

solar resources, and the outcome becomes even more favourable once the damage to the health of the petrochemicals workforce is brought into the equation.

The Leitfaden Nachwachsende Rohstoffe (Handbook of Renewable Resources) compares the market prices for fossil and solar resources. A summary is presented in Table 7.1.

The table distinguishes between raw materials, precursors and intermediate products, and compares fossil and solar substances used to manufacture comparable products. The table also shows that, whereas fossil raw materials require complicated processing to produce the required precursor chemicals, in the case of solar resources, the precursor is the natural state of the raw material – or only requires simple processing to extract the sugar, molasses or starch. Two of the solar raw materials listed, and even more of the precursors, are already cheaper than their fossil equivalents; the price differences for the intermediate products are small. The slightly higher prices for solar intermediate products cannot be because it is fundamentally more expensive to process solar raw materials into precursor chemicals; the opposite is the case. The real reason for the higher costs is to do with quantity. As more care can and must be taken when selecting particular solar precursor or intermediate products, there is less scope for economies

THE UNTAPPED WEALTH OF SOLAR RESOURCES 215

of scale than with fossil resources. In any case, industrial processing of solar materials is still in the early stages.

There are already many practical examples of the multifarious productivity and environmental benefits that can flow from the industrial exploitation of solar materials, as Hermann Fischer documents in his book Plädoyer für eine sanfte Chemie (The Case for Soft Chemistry). Fischer uses 34 criteria to perform a systematic comparison of fossil and solar resources as employed in the production of paints, covering source raw material through to product use and disposal. Only on one criterion, ease of use, do synthetic paints outperform natural ones, and this is primarily the result of a century of industrial research and development. Natural paints could easily catch up if industry and academia were to devote more time and effort to the issue. On only one further criterion – shelf-life – do both perform equally; on all the other 32 criteria, natural paints have a significant edge (see Table 7.2).

The economic advantages of solar resources are also documented by a large number of examples in many other areas. For instance, the car manufacturer Daimler has concluded, after experimenting with plastic reinforced by natural fibres, that natural fibres require far less energy to process than glass fibre. Everything can be recycled without significantly compromising on the technical specifications – of particular relevance to the automobile business, given the impending legal obligation on car manufacturers to take responsibility for old cars. A weight reduction of 10–30 per cent favours energy-efficient light construction techniques. Natural fibres are also beneficial to workplace health, as they cause less skin and lung irritation. Lower prices and reduced processing time also reduce the cost of manufacturing the respective components by 10–30 per cent.9 Industry also reports numerous advantages from its experience with lubricants derived from vegetable oil: reduced evaporation, less wear and tear on motors or machinery, longer lifetime, no microbial decomposition, no waste disposal costs, reduced materials maintenance due to better sealant properties, no risk to water quality, more favourable temperature/viscosity relationship, no need for continual supervision. These biolubricants cost between two and five

216 THROWING OFF THE FOSSIL SUPPLY CHAINS

Table 7.2 Comparative evaluation of products manufactured from fossil and solar raw materials

|

Colours from crude oil or colours from plants? |

|

||

|

(Comparative environmental impact assessment of the main |

|||

|

components in paints: adhesives, solvents, organic |

|||

|

pigments, additives) |

|

||

Criterion |

Synthetic colours |

Mark |

Natural colours |

Mark |

|

|

|

|

|

a) Raw material |

|

|

|

|

Origin |

Crude oil |

– – |

Plants |

++ |

Renewable source? |

No |

– – |

Yes |

++ |

Availability |

Very limited |

– – |

Unlimited |

++ |

Global distribution |

Very uneven |

– – |

Near universal |

++ |

Producers |

Corporate monopolies |

– – |

Regional producers |

++ |

Toxicology |

Highly toxic |

– – |

Mildly or non-toxic |

+ |

Environmental impact |

Highly damaging |

– – |

Harmless |

++ |

b) Synthesis |

|

|

|

|

Basic principle |

Industrial synthesis |

– – |

Photosynthesis |

++ |

Where synthesized |

Reaction chamber |

– – |

Within plants |

++ |

How organized |

Centrally |

– – |

Locally |

++ |

Energy requirements |

Very high |

– – |

Low |

++ |

Energy source |

Oil, coal, nuclear |

– – |

Direct solar energy |

++ |

Chemical structures |

Highly artificial |

– – |

Natural structures |

++ |

Process control |

Costly |

– |

Self-regulating |

++ |

Risk of accident |

Very high |

– – |

None |

++ |

Effect of accidents |

Sometimes disastrous |

– – |

None |

++ |

Security requirements |

Very high |

– – |

Very low |

++ |

Fault tolerance |

Very low |

– – |

Very high |

++ |

Emissions |

High |

– – |

None |

++ |

Quantity of waste |

Very high |

– – |

None |

++ |

Type of waste |

Highly toxic in parts |

– – |

(Oxygen) |

++ |

Social costs |

Very high |

– – |

Low |

++ |

c) Product use |

|

|

|

|

Chemical pollutants |

Can be considerable |

– – |

None |

++ |

Effect of inhalation |

Mostly harmful |

– |

Mostly harmless |

+ |

Odour (solvents and |

|

|

|

|

ancillary chemicals) |

Overpoweringly artificial – – |

Pleasantly natural |

++ |

|

Colour aesthetics |

Loud, glaring |

– – |

Lively, harmonious |

++ |

Tactile quality |

Unpleasant, smooth |

– – |

Pleasant to the touch |

++ |

Electrostatic properties |

Collects a high charge |

– |

Charge usually low |

+ |

Effect on indoor climate Often negative |

– |

Highly positive |

++ |

|

Ease of use |

Good to very good |

++ |

Good |

+ |

Durability |

Good |

+ |

Good |

+ |

d) Disposal |

|

|

|

|

Biodegradability |

Sometimes very poor |

– |

Complete |

++ |

Rate of decomposition |

Sometimes very slow |

– |

Very fast |

++ |

Atmospheric impact |

Greenhouse effect |

– – |

None (circular flow) |

++ |

|

|

|

|

|

Source: Hermann Fischer, Plädoyer für eine sanfte Chemie (The Case for Soft Chemistry)10

THE UNTAPPED WEALTH OF SOLAR RESOURCES 217

times as much as standard fossil hydrocarbon lubricants, but scarcely more than fossil hydrocarbon lubricants of equivalent quality. Even with the current state of knowledge, 90 per cent of all lubricants could be replaced with ones derived from vegetable oil.11 Even today, biolubricants have an economic advantage once the qualitative advantages have been taken into account.

Only in the realm of medicine have plant materials made significant inroads. Plant-derived remedies, produced from a wide variety of medicinal herbs, already make up 30 per cent of the market for medicines in Germany.12 Henkel is one of the few large chemicals companies which also uses solar materials in its other products, from natural-fibre-reinforced plastic rather than fibreglass through surface chemistry to adhesives, cleaning agents and cosmetics. For some products, cleaning agents in particular, the entire product line is now manufactured from solar sources.13 Already, one can point to a panoply of further examples, involving different solar resources in each case: chitin, extracted from insect exoskeletons or from fungi, is used to make the polymer chitoson, which has applications, among others, as a preservative, in catalytic converters and as packaging; new materials derived from pea starch; the use of starchy potatoes, whose juice contains nitrates and potash, in composite materials, space-filling packaging and cushioning material or plastic film; the use of plant fibres and cellulose in insulation and foams; packaging materials made from maize; the many and varied uses of hemp or flax in textiles, building materials, medicines or paper; high-performance fibres made from banana stems. In all cases, the products are biodegradable and can be recycled naturally.

Native plants already contain usable materials which it would require highly toxic and complex procedures to produce from fossil resources. As Fischer puts it, plants:

never [form] a single substance or even a single class of materials. Even the simple conifers simultaneously synthesize cellulose, lignin, dyes, tannins, chlorophyll, vegetable waxes in the cuticle of its needles, essential oils, resins, turpentines, oiland protein-rich cones and thousands of other easily used

218 THROWING OFF THE FOSSIL SUPPLY CHAINS

and sought-after natural materials. Every single species of most plant genera offers almost the entire range of plant products. It therefore makes sense not to harvest a plant for the sake of just one material, but as far as possible, to use every part of it.14

Solar resources offer obvious advantages for industrial processing. To exploit them, however, would necessitate a departure from the industrial monoculture of the chemical industry. Solar resources, therefore, represent an opportunity for small and medium-sized enterprises to establish themselves on the market for chemical products.

The chemical industry in Germany consumes 13 million tonnes of crude oil, 2.7 million tonnes of natural gas, 1.5 million tonnes of coal and 1.8 million tonnes of vegetable matter annually. The latter is primarily used to produce 450,000 tonnes of starch, 250,000 tonnes of cellulose and 900,000 tonnes of vegetable oils and fats.15 The enormous potential of solar resources has hitherto not been fully exploited. There are a wide variety of reasons for this. Manufacturers of biochemical products are mostly small, and are forced, through lack of large marketing arms, to rely on specialist markets. Chemistry research is overwhelmingly funded by the petrochemicals industry. And the knee-jerk prejudices and uninformed nature of the environmental movement, which specializes in conserving nature without utilizing it, have held campaigners back from forcing a fundamental rethink in the chemicals industry.

Replacing fossil with solar resources

According to Römpps Chemical Lexicon, the global chemical industry consumes around 900 million tonnes of fossil raw material every year. By comparison, the biosphere produces 1.7 trillion tonnes a year on the land surface alone, almost 2000 times greater than the entire annual demand for petrochemical products.16 At the fourth international conference on Solar Energy Storage and Applied Photochemistry in January 1997 in Cairo, it was calculated that the chemical industry’s total

THE UNTAPPED WEALTH OF SOLAR RESOURCES 219

annual output of materials is only 0.02 per cent of the total annual output from nature.17

The UNEP’s Global Biodiversity Assessment cites 10 to 100 million plant species.18 In his book Nutzpflanzenkunde (Crop Science), Wolfgang Franke writes of 400,000 known species, of which 20,000, or 5 per cent, are used as foodstuffs, medicines, for pleasure or as raw materials. However, only 5000 species are cultivated, and only 660 are major agricultural crops.19 Few people have recognized, and then only in part, the number of uses to which a plant can be put. Even isolated examples expose a fascinating panorama of possibilities. In all likelihood, therefore, the variety of products which can be made from the ‘rediscovered’ hemp plant, as collated in a muchrespected book,20 was only the tip of the iceberg. The book listed only historically documented uses. How many more await discovery will only be known when materials scientists finally devote real research time to the subject. Several hundred new products might quickly result. The same probably goes for almost all the 400,000 known and innumerable unknown plant species.

It may be impossible to put a figure on the full spectrum of possible materials. It will greatly exceed the number of registered chemicals. Estimates to the effect that science has uncovered considerably less than 1 per cent of what is actually possible are not overly conservative. Part of this knowledge is which plants produce the greatest and qualitatively most valuable yield for which purpose under what conditions. Yet instead of seeing this potential as an opportunity for a comprehensive greening of the chemical industry, the world is being held by the fossil energy and materials industry in a state of economic monoculture which stands in ever more dramatic contrast to the growing diversity of opportunity. It would doubtless be possible, compound for compound, to find photochemical replacements for the entire spectrum of petrochemical products.

But what about the other group of non-renewable resources, the mineral ores? In its publication Mineralische Rohstoffe. Bausteine für die Wirtschaft (Mineral Ores: Components for Industry), the German Federal Institute for Geological Sciences and Raw

220 THROWING OFF THE FOSSIL SUPPLY CHAINS

Materials lists substitute materials for 12 important metals, of which seven have already been partially replaced. Casings, pipes, oil pipelines, filters, household appliances, windows and doors, sewers, gutters and packaging are already being made from plastic rather than copper, aluminium, brass, steel, lead, zinc or tin.21 It follows that they can also be made from solar materials. The list could be extended ad infinitum: from car bodies to aeroplane fuselages and wings, from ship hulls to tanks and cables. One of the greatest opportunities is the replacement of aluminium by wood as a construction material

– it is no coincidence that wood-frame buildings are experiencing a renaissance.

All these examples are no more than snapshots. Solar materials are poised for a new beginning and an all but unlimited new realm of scientific and technical possibilities. As this development gets in train, further opportunities for replacing metals will open up. Even if not all metals can be replaced (for example, those which are good conductors or highly refractory), solar materials present a real opportunity for a drastic reduction in the consumption of conventional raw materials.

Solar materials: from agricultural monocultures to polycultures

The chemical industry’s argument that the ‘costs are too high’ is not the only objection raised to solar materials (and by extension to the replacement of fossil resources). There are a further two stock arguments drawn from the conservation debate, and these also crop up time and again in connection with the use of biomass as an energy source.

1The first argument is that solar resources compete with food production for land, hence there are ‘ethical reasons’ for sticking with fossil petrochemistry, because otherwise there would not be enough arable land to produce the necessary quantities of food. This reasoning, however, is not tenable, as the data on worldwide arable land area in Chapter 2 indicate. Natural photosynthetic production is entirely capable of replacing the third of annual oil output

THE UNTAPPED WEALTH OF SOLAR RESOURCES 221

consumed by the chemicals industry, and quite possibly more besides.

2Secondly, critics cite the danger of over-farming the land and of agricultural monocultures. Yet it is doubtful that these tendencies would automatically be exacerbated by the use of solar resources as an energy source and as raw materials. From the earlier discussion on solar resources as an energy source, the conclusion has already been drawn that this is not the case, provided that such energy crops are harnessed in the technologically and economically optimum manner.

Studies such as the one by David O Hall and Frank RosilloCalle show that the danger of soil erosion and consumption of fertilizers and pesticides are considerably less for energy crops than for food crops. On a comparison between coppiced woodland (eg willow trees) and corn, wheat or soya beans, the danger of erosion is 12.5 times smaller, fertilizer consumption 2.1 times smaller, herbicide use 4.4 times smaller, insecticide use 19 times smaller and fungicide use 39 times smaller.22 The Swedes have found that, if harnessed in the right way, biomass does not result in significant damage to the environment.23 And that is even without looking at proposals involving shortrotation cropping or at the possibility of doing completely without artificial fertilizers and pesticides. Energy crops thus place a far lesser burden on the land than do food crops.

Harnessing plants as raw materials is by no means just a matter of quantity: it is a matter of quality as well. As previously discussed, unlike fossil resources, the quality of solar resources in their natural state is so high that increasing use of ever more products must necessarily favour or even trigger a shift from monoto polycultures.

Monocultures occur in food production, which has concentrated on ever fewer species and varieties, principally maize, wheat, rice and potatoes, but they are by no means inevitable in the cultivation of solar resources. In order to exploit the variety of substances directly produced by plants, a great variety of specialized crops must be cultivated. Admittedly, the very low yields for many coveted substances, such as essential oils, are a