- •Syllabus

- •Well completion design

- •High Technology Wells

- •Production from oil rims

- •Intrawell gas lift

- •Alternating gas production

- •Improving sweep efficiency in a system of injection and production wells

- •Example

- •Problem setup

- •Drainage Strategy

- •Well completion scenario

- •Simulation Results: Cumulative oil production with ICVs and its incremental volumes as compared with ordinary completion wells

- •Discounted effect, ICVs performance

- •Position of ICV in one of the wells

- •Well perforation

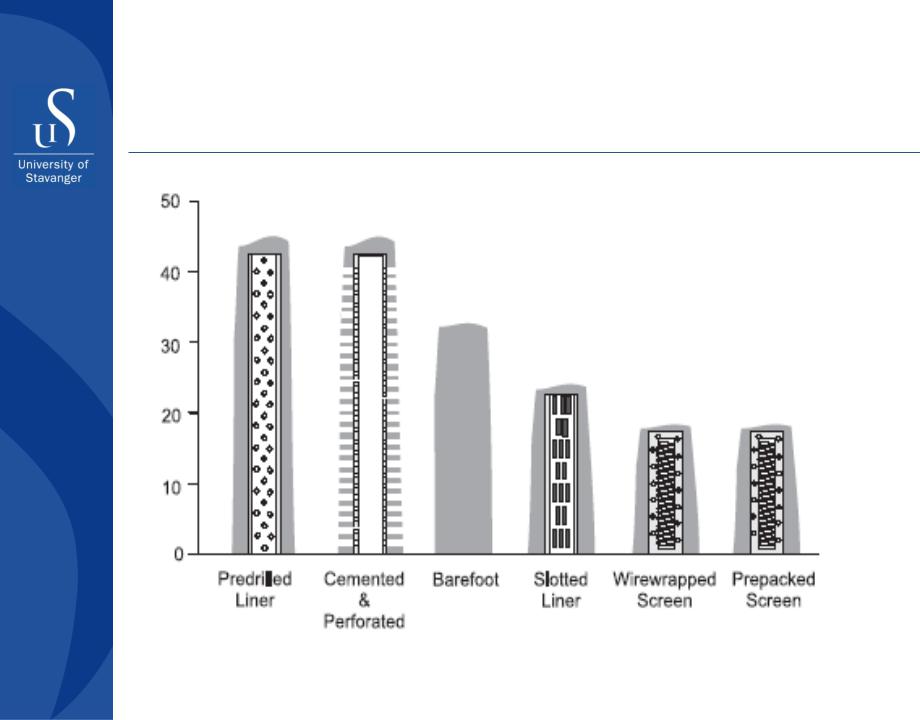

- •Sand Control

- •Syllabus

- •Examples of developing materials with improved erosion resistance

Modern

Well Stimulation

Methods

Prof. Anatoly Zolotukhin

Part II - Well completion design

Syllabus

Selecting drainage strategy and well placement system (6 hours)

Well completion design (6 hours)

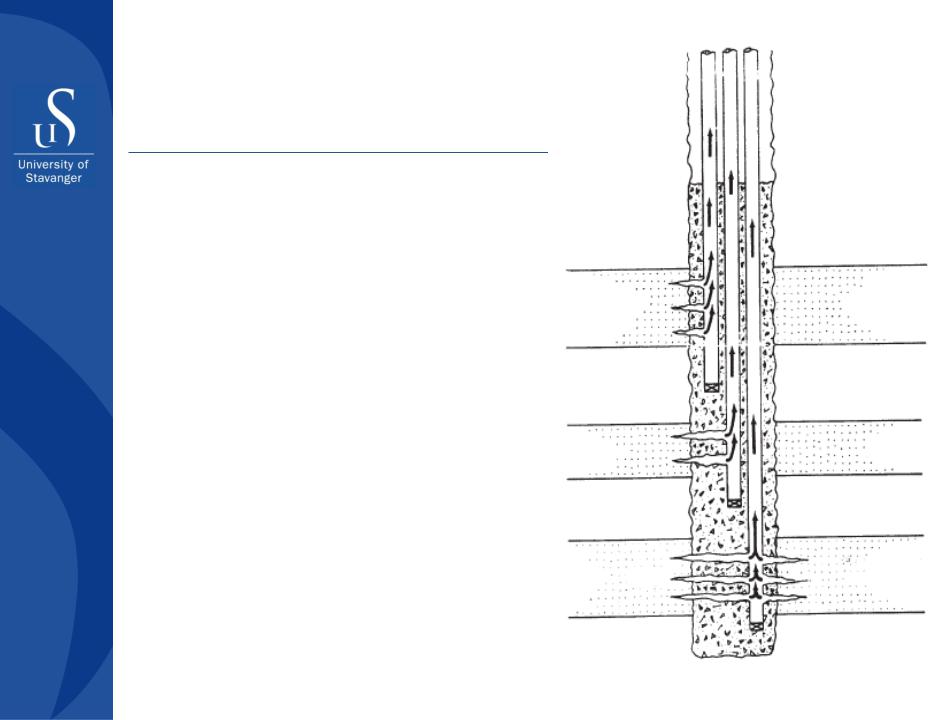

–Well perforation

–Sand control

–Gravel pack

Well stimulation methods (8 hours)

–Acid washing and matrix acidizing

–Hydraulic fracturing

–Horizontal drilling

Well productivity estimating methods (8 hours)

–Productivity of a well with arbitrary trajectory

–Well interference

Final test (exam, 2 hours)

Part II - Well completion design

Part II

Well completion design

Part II - Well completion design |

3 |

Well completion design

Ideal completion means the lowest cost completion (i.e. initial and operating cost) that meets or nearly meets the demands placed upon it for most of its life

Part II - Well completion design |

4 |

Factors influencing well completion design

Production rate – a starting point for WCD

Multiple reservoirs

–Multiple completion inside casing, several strings or smaller casing cemented in one borehole, different types of multilateral wells, commingled production, etc.

Recovery drive mechanism

–Secondary recovery methods – selective injection/production interval should be considered

Well stimulation

–May require zonal isolation

Sand control

Part II - Well completion design |

5 |

From the mechanical consideration point of view WCD should:

Maximize profit

Keep the installation simple

Ensure an overall reliability and safety

Anticipate all operation conditions

Part II - Well completion design |

6 |

Well Completion

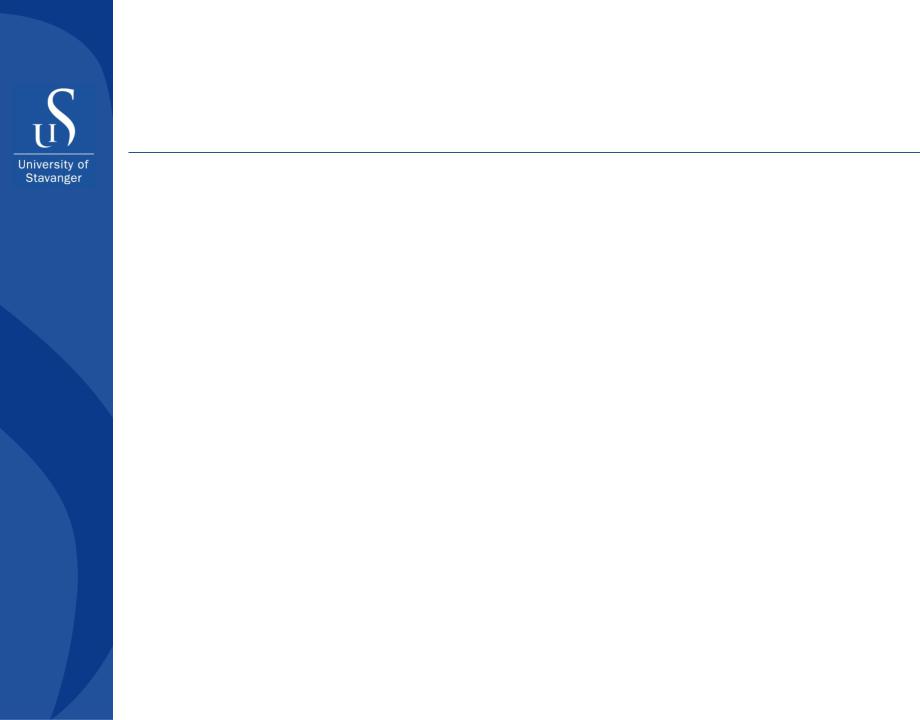

Single completion. Open borehole

Part II - Well completion design |

7 |

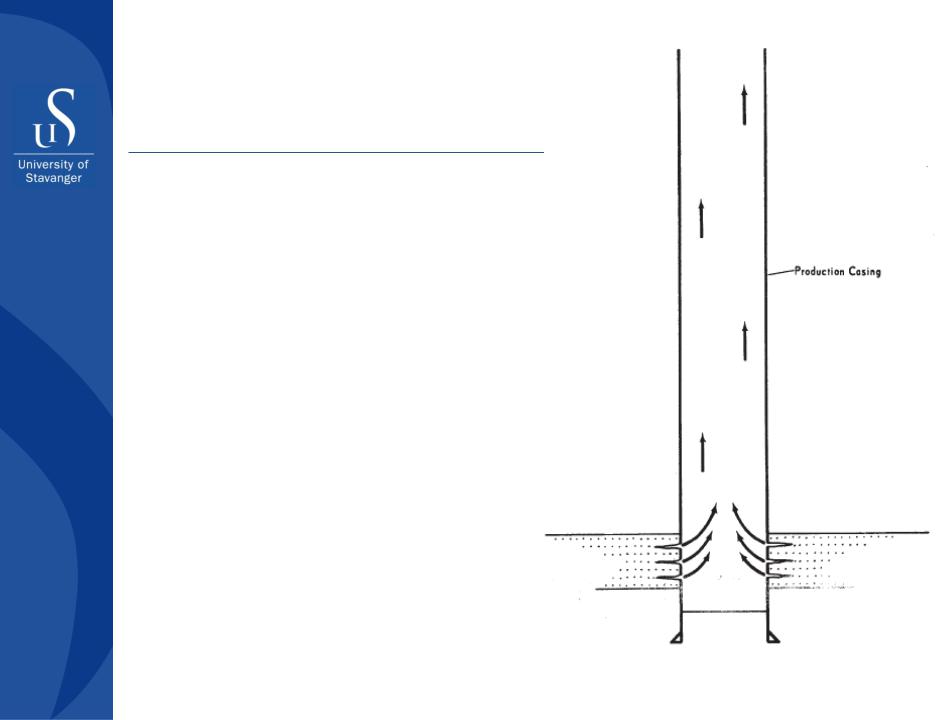

Well Completion

Single completion. Production tubing

Part II - Well completion design |

8 |

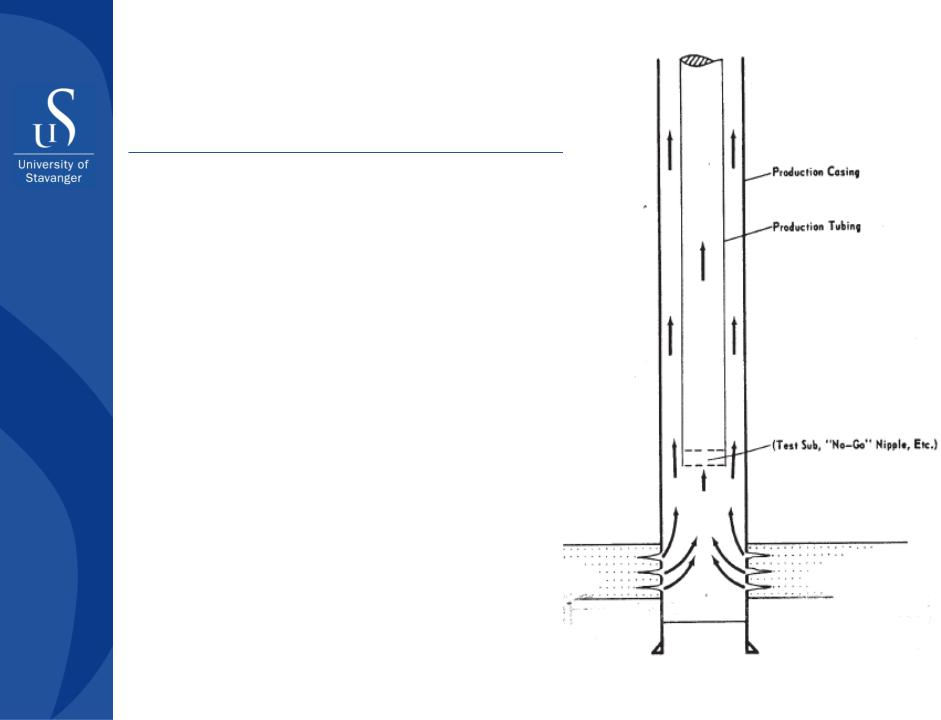

Well Completion

Single completion with single packer and string

Part II - Well completion design |

9 |

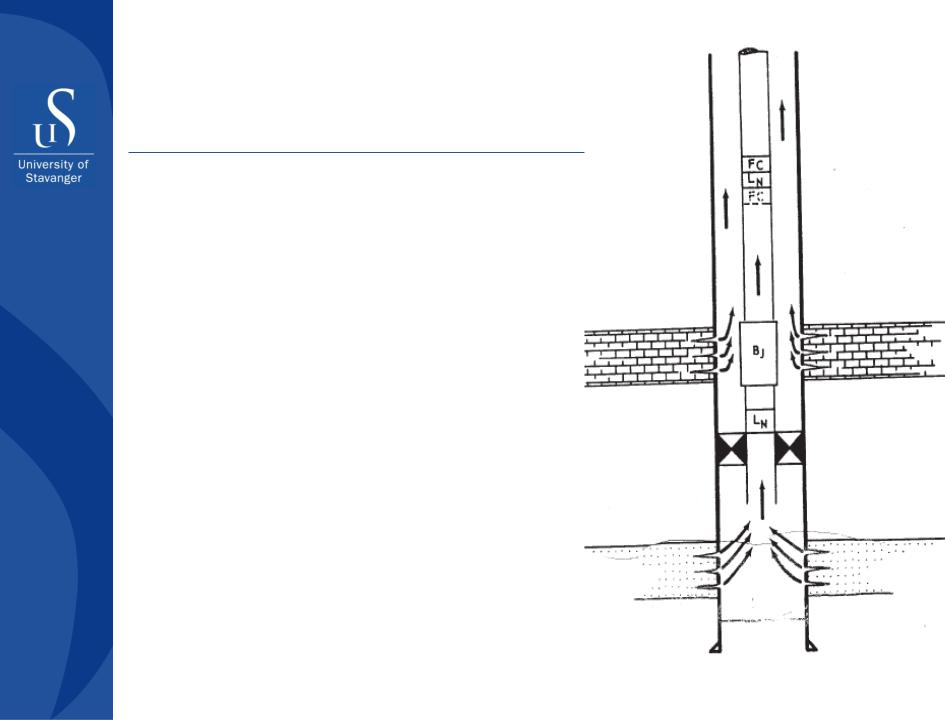

Well Completion

Dual completion with single packer and single string

Part II - Well completion design |

10 |

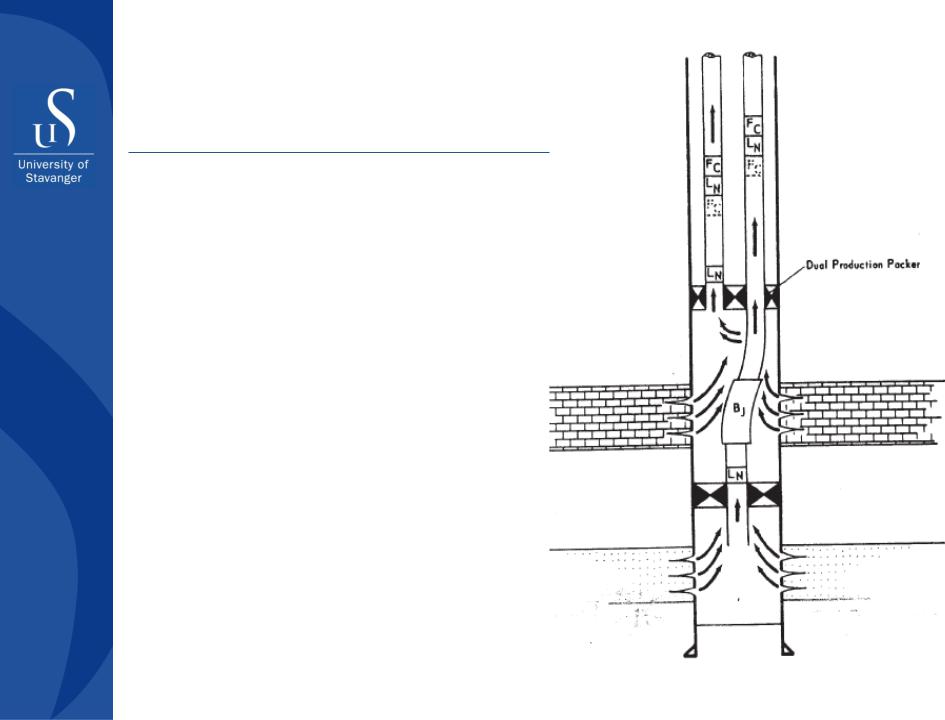

Well Completion

Parallel dual completion with two packers and two tubing strings

Part II - Well completion design |

11 |

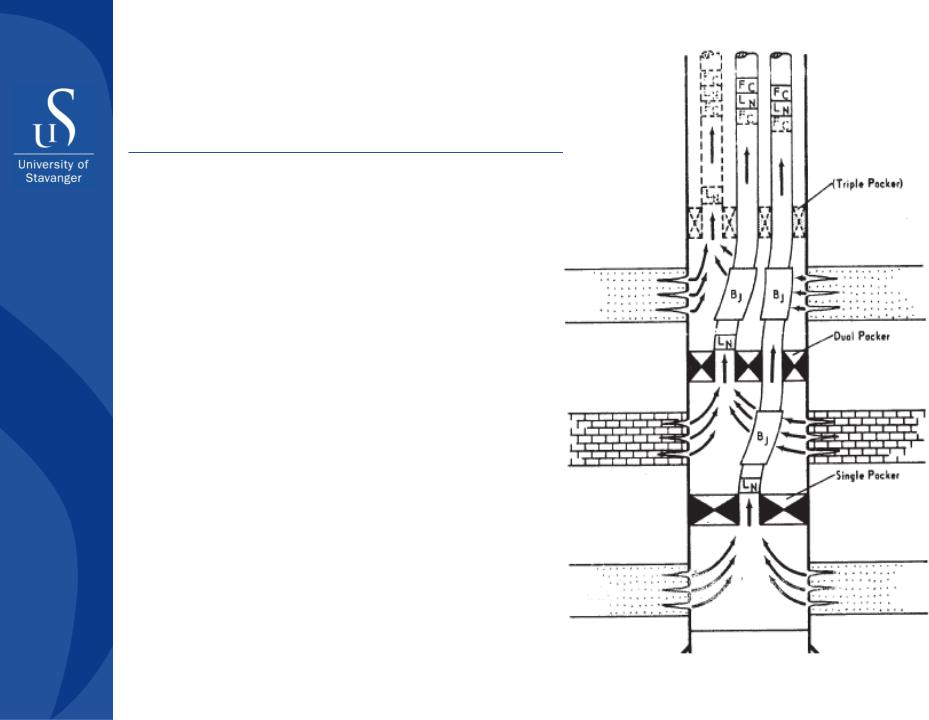

Well Completion

Triple completion with two or three packers and two or three tubing strings

Part II - Well completion design |

12 |

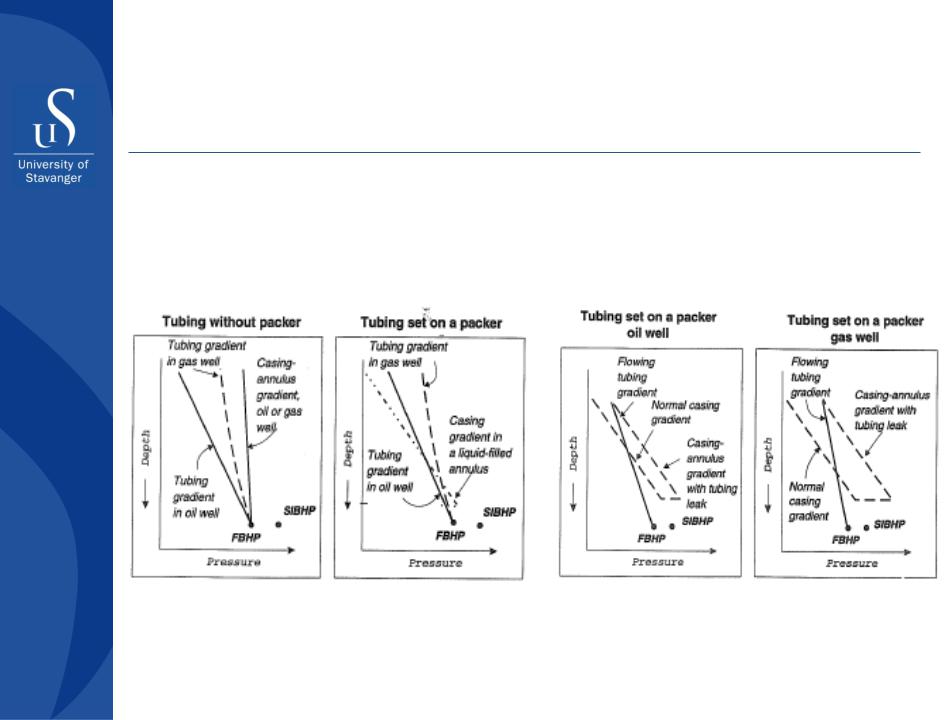

Well Completion

Effect of Tubing and Packer on Pressure Gradient in Well

Part II - Well completion design |

13 |

Well Completion

Multiple tubingless completion

Part II - Well completion design |

14 |

Well Completion

Completion techniques used for horizontal wells

Part II - Well completion design |

15 |

Well Completion Design

Artificial lift position

Multilateral junction node point

Liner pressure drop

Inflow Performance

(lateral 1)

Liner pressure drop

Inflow Performance

Inflow Performance

(lateral 2)

Part II - Well completion design |

16 |

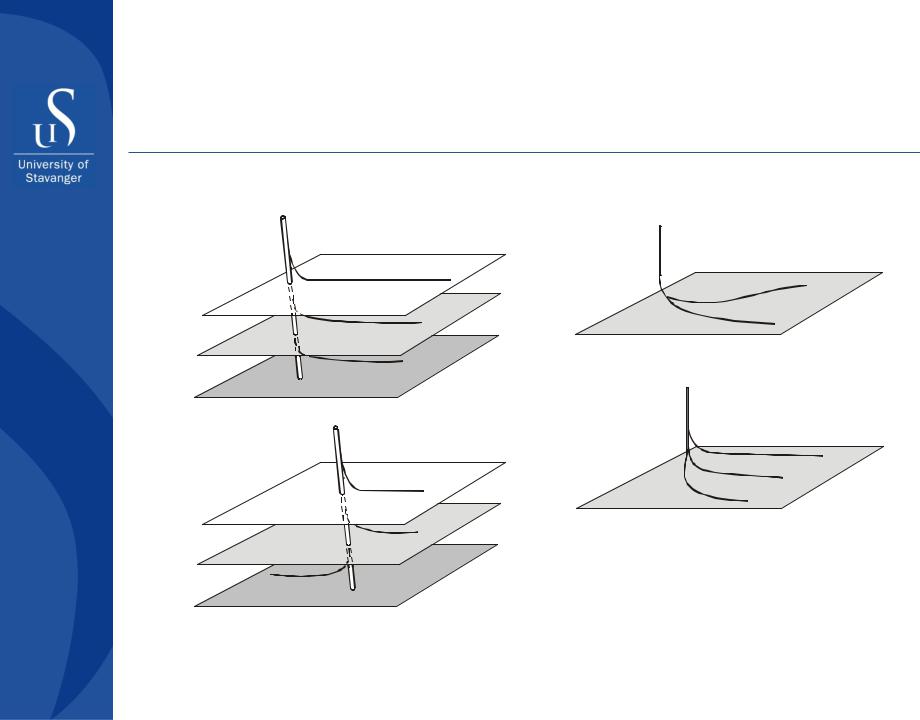

Well Completion Design

a) |

b) |

c) |

d) |

Part II - Well completion design |

17 |

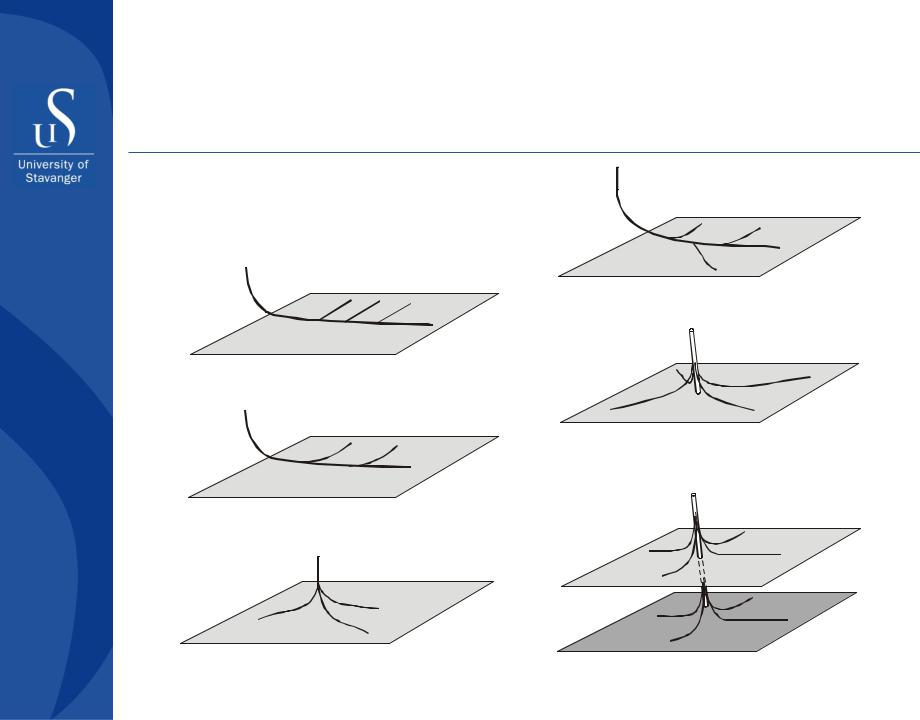

Well Completion Design

e) |

f) |

g) |

h) |

i) |

j) |

Part II - Well completion design |

18 |

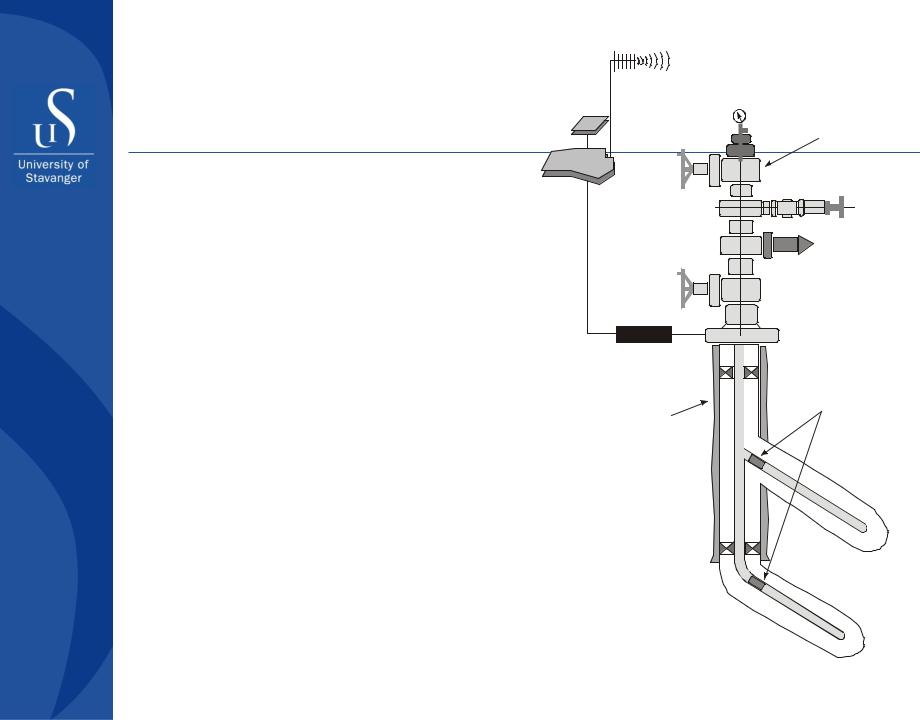

Well Completion

Design

Remote

Telemetry System

Wellhead

Downhole

Control

Valves with

Integral Sensors

Hard Wired

Downhole

Telemetry

System

Part II - Well completion design |

19 |

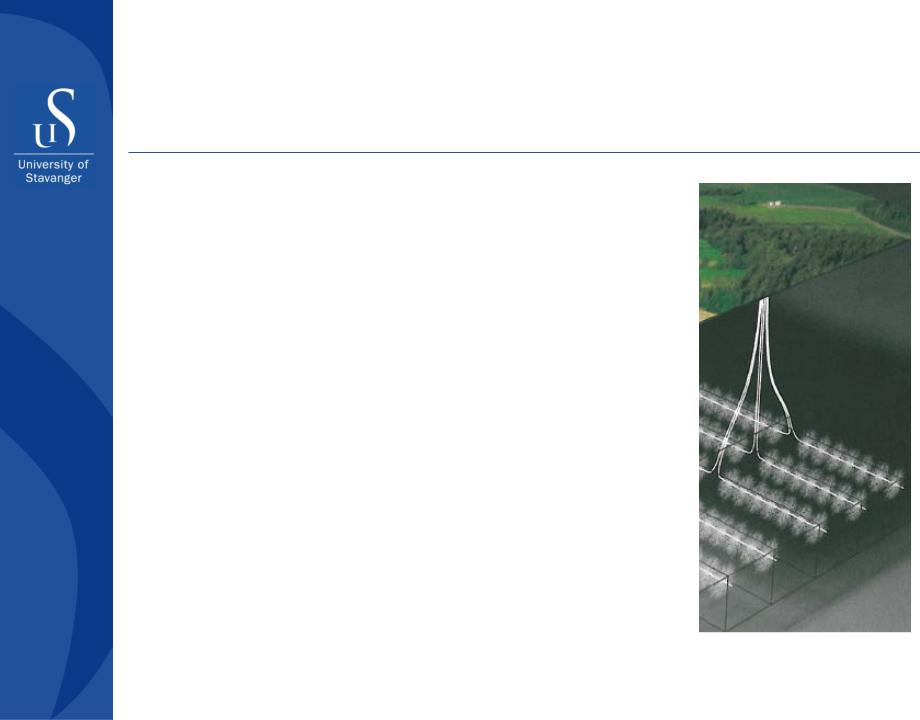

Shale gas production technology

Technology

Wells are drilled vertically into the shale formations and then 500 – 1500 meters horizontally through them

The next step is to fracture the rock

After perforating the lower end of the production liner the well is filled with water and sand

The shale is then fractrured by pumping the water + sand into it under high pressure

Source: Marcellus shale gas production, Statoil, 2010

September 21, 2013 |

PetParoleumtII - WellPolicycompletionand Operations,design |

20 |

|

PETRAD |

|