- •Syllabus

- •Well completion design

- •High Technology Wells

- •Production from oil rims

- •Intrawell gas lift

- •Alternating gas production

- •Improving sweep efficiency in a system of injection and production wells

- •Example

- •Problem setup

- •Drainage Strategy

- •Well completion scenario

- •Simulation Results: Cumulative oil production with ICVs and its incremental volumes as compared with ordinary completion wells

- •Discounted effect, ICVs performance

- •Position of ICV in one of the wells

- •Well perforation

- •Sand Control

- •Syllabus

- •Examples of developing materials with improved erosion resistance

Section 3

Sand Control

Part II - Well completion design

Syllabus

Sand control

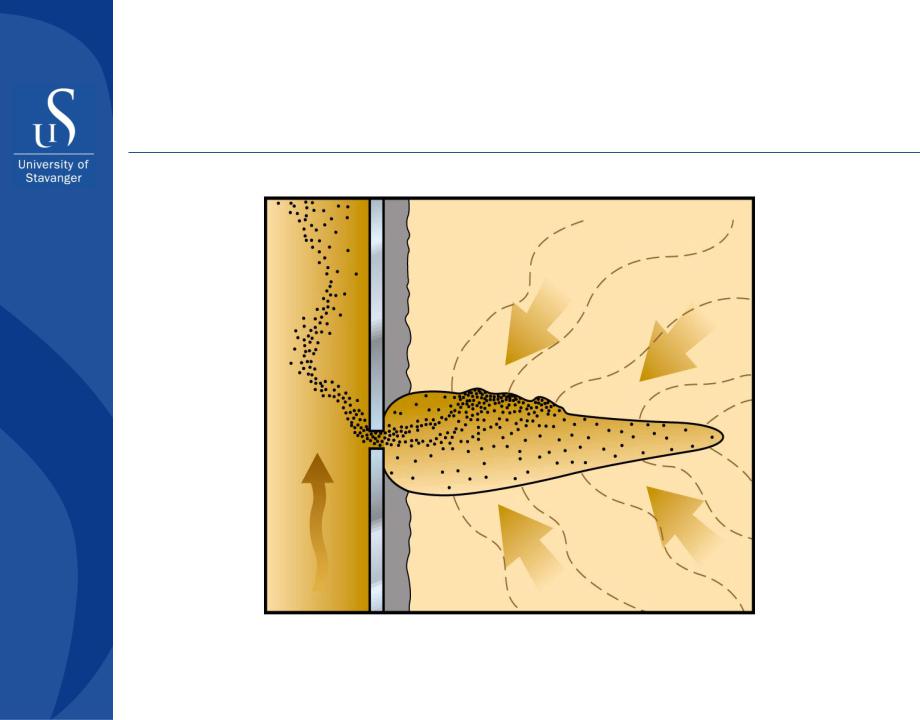

Problems in production from unconsolidated sands

−Sand influx and productivity of a well

−Sand failure mechanisms: sand bridging, sand arching

Gravel packing

−Gravel size selection

−Porosity and permeability of gravel packs

−Liner of screen selection

−Gravel placement

Gravel packing in deviated and horizontal wells

Part II - Well completion design

Sand management in StatoilHydro

Part II - Well completion design

Sand management

Elements in Sand Management

1.Rock mechanical data acquisition

2.Sand production prediction

3.Sand control

4.Erosion risk management

Part II - Well completion design

Sand management

Rock mechanical data acquisition

Part II - Well completion design

Rock mechanical data acquisition for sand prediction

High quality data acquisition is the basis for all rock mechanics, including

•Sand prediction

•Stress in the formation

•Mechanical properties of the formation

Part II - Well completion design

Rock mechanical data acquisition for sand prediction

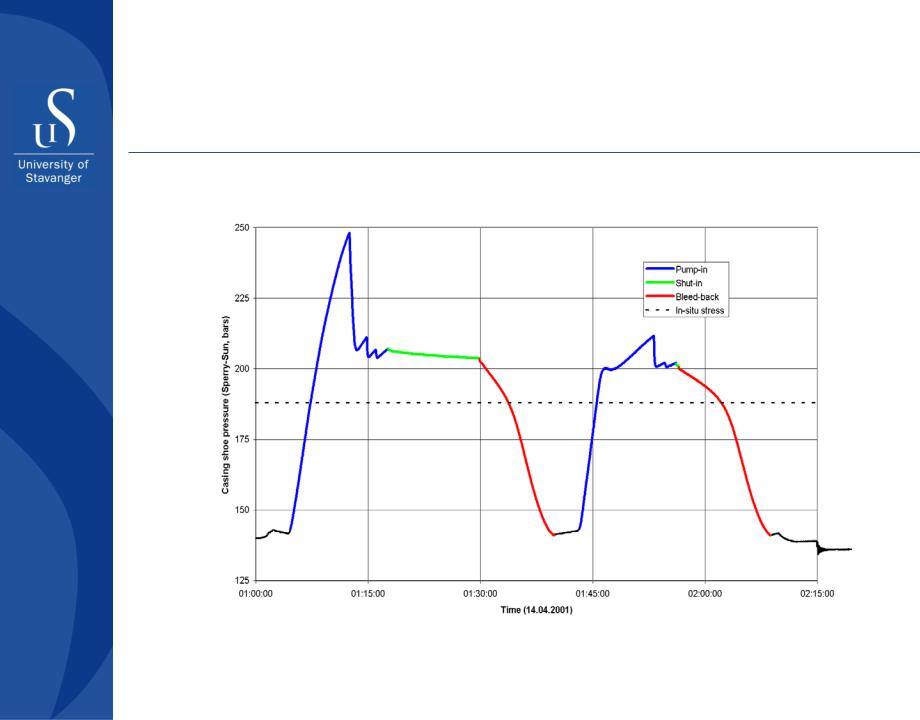

XLOT to derive magnitude of minor horizontal stress

Part II - Well completion design

Rock mechanical data acquisition for sand prediction

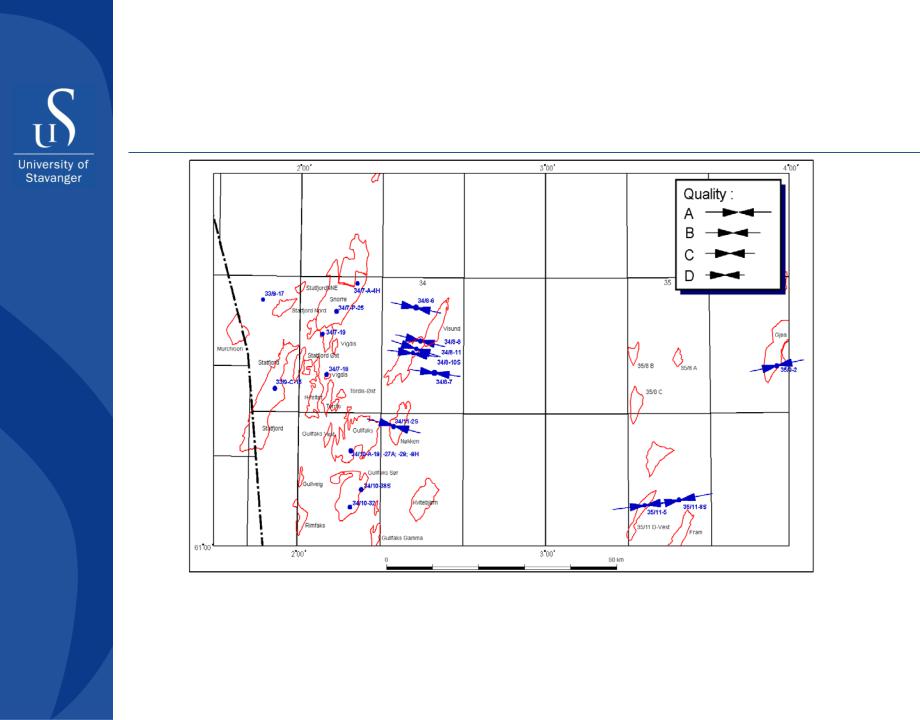

Stress direction based on breakout and drilling induced fractures from image logs

Direction of major horizontal stress in the Tampen area in the North Sea.

Blue dots indicate wells where no breakout or drilling induced fractures were found.

Part II - Well completion design

Sand management

Sand production prediction

Part II - Well completion design

Sand production prediction

A key element in sand management

No sand production expected |

Strong reservoir |

independent of well direction |

|

and perforation strategy |

|

Possible outcome of sand

prediction

Sand production can be |

Medium |

|

avoided by a carefully |

|

|

chosen well direction or |

|

|

perforation strategy |

|

|

Independent of perforation |

|

|

strategy, the well will produce |

|

|

sand if the rate is above |

|

Weak |

maximum sand-free rate |

||

Strategy:

Use sand prediction in design, avoid sand control when possible

Use mechanical sand control or produce at maximum acceptable sand rate

Part II - Well completion design

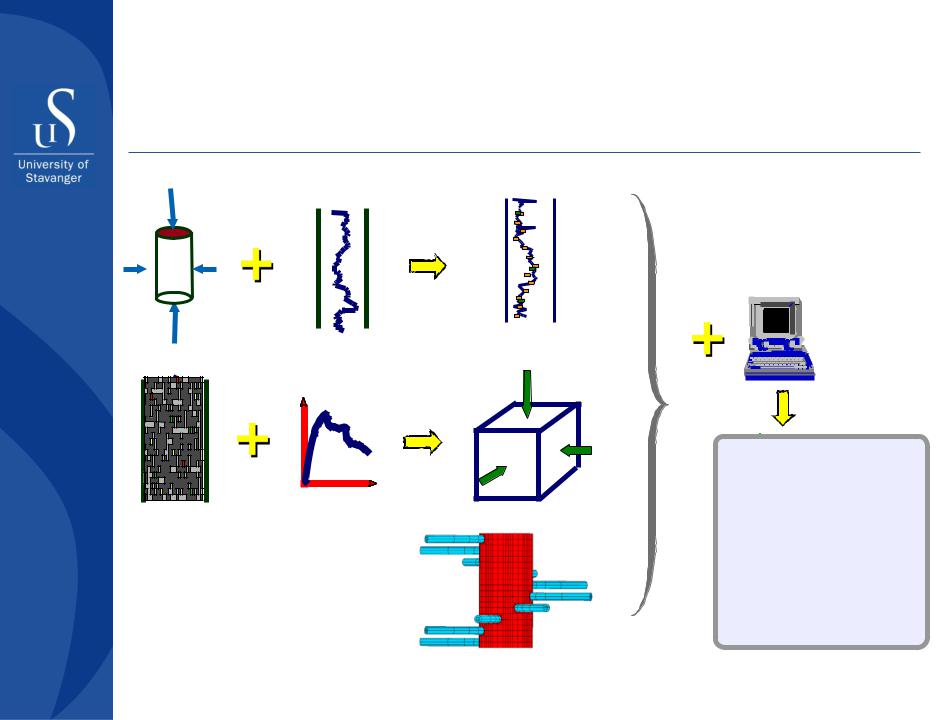

Sand production prediction methodology

Strength testing |

Borehole logs |

Formation strength |

Stability simulation by use of FEM

Image log |

Minifrac or XLOT |

Stress state |

Pressure

Time |

Geometry/boundary conditions

Sand production potential as a function of perforation geometry, reservoir depletion and drawdown

Part II - Well completion design

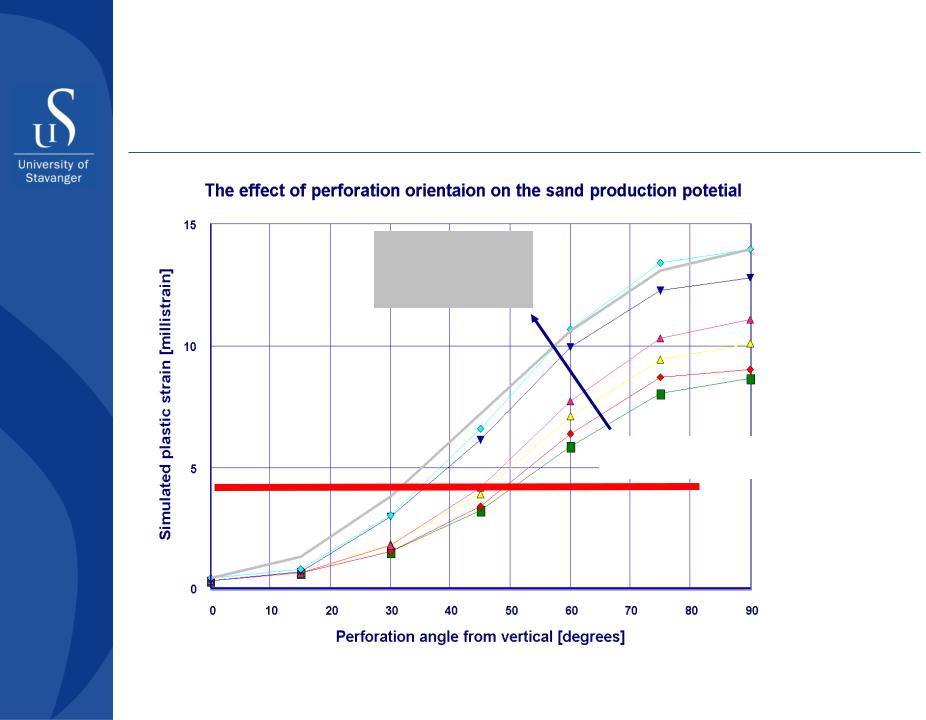

Sand production prediction

Effect of perforation orientation in a horizontal well

Increasing drawdown and depletion

Expected sand production above red line

Part II - Well completion design

Sand management

Sand control

Part II - Well completion design

Sand control

Statoil practice the last decade

Mechanical sand control installed in more than 200 Statoil wells since 1994:

•25% Cased hole gravel pack

•25% Stand alone screen in open hole

•50% Open hole gravel pack

•A couple of frac packs (both cased hole and open hole)

Statoil’s present sand control strategy:

•Open hole completions to reduce risk of plugging

•Frac pack to stimulate productivity in stratified reservoirs

Part II - Well completion design

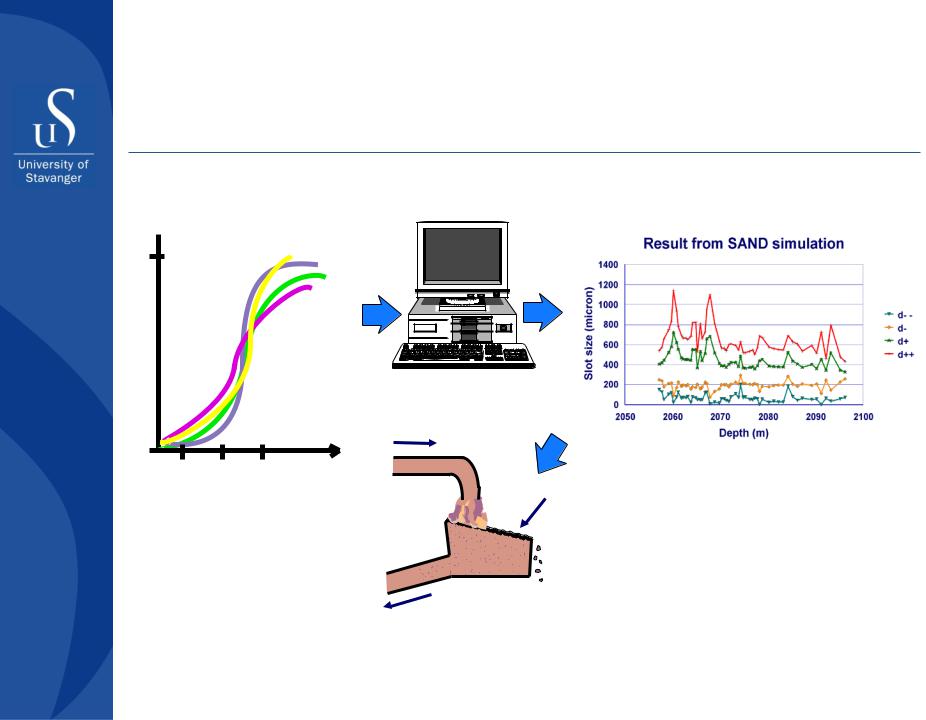

Sand control

Sizing screen for open hole application

|

Particle size |

|

|

100 |

distribution of |

Computer |

|

formation |

|||

% |

program |

||

|

|||

|

|

SAND |

0% |

|

|

0,01 |

0,1 |

1,0 |

|

|

Shake |

|

|

r |

|

|

scree |

|

|

n |

Screen slot size to be selected between d- and d+

Sand-screen slot size dictate mud conditioning

Part II - Well completion design

Sand control

Testing the mechanical strength of screens

Part II - Well completion design

Sand control

Failure mode of certain types of wire wrapped screens

Part II - Well completion design

Sand management

Erosion risk management

Part II - Well completion design

Erosion risk management

Examples of choke erosion

Part II - Well completion design

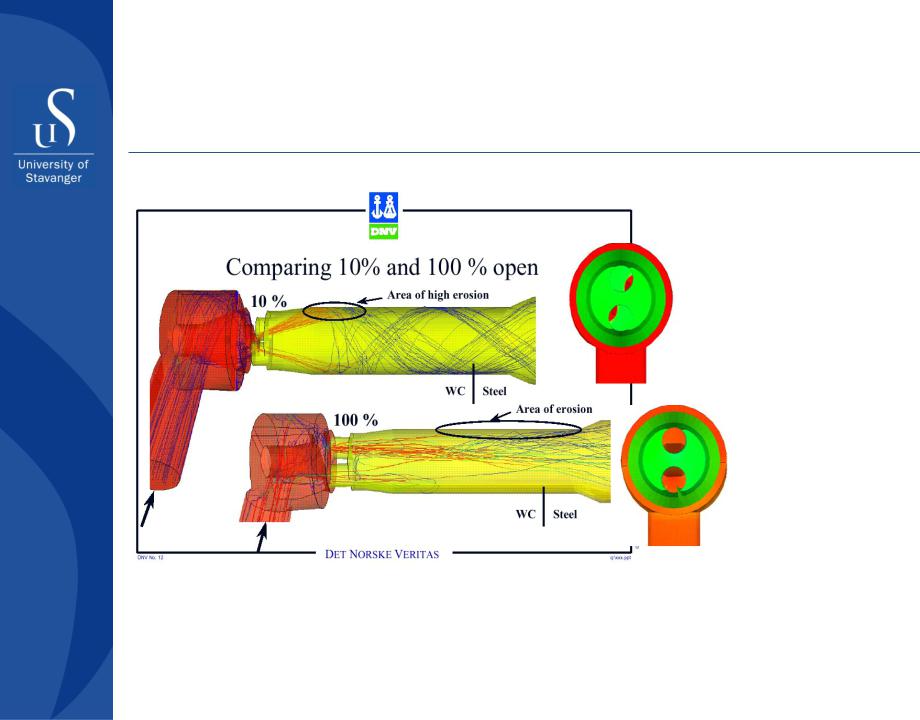

Erosion risk management

Examples of erosion modeling by CFD

Simulations show that wells with high gas production and small choke opening will experience concentrated erosion where the outlet jets hit the pipe wall (upper figure).

By changing to choke discs with smaller holes that can be operated fully, or close to fully open, the erosion rate will be dramatically reduced (lower figure).

Part II - Well completion design

Erosion risk management

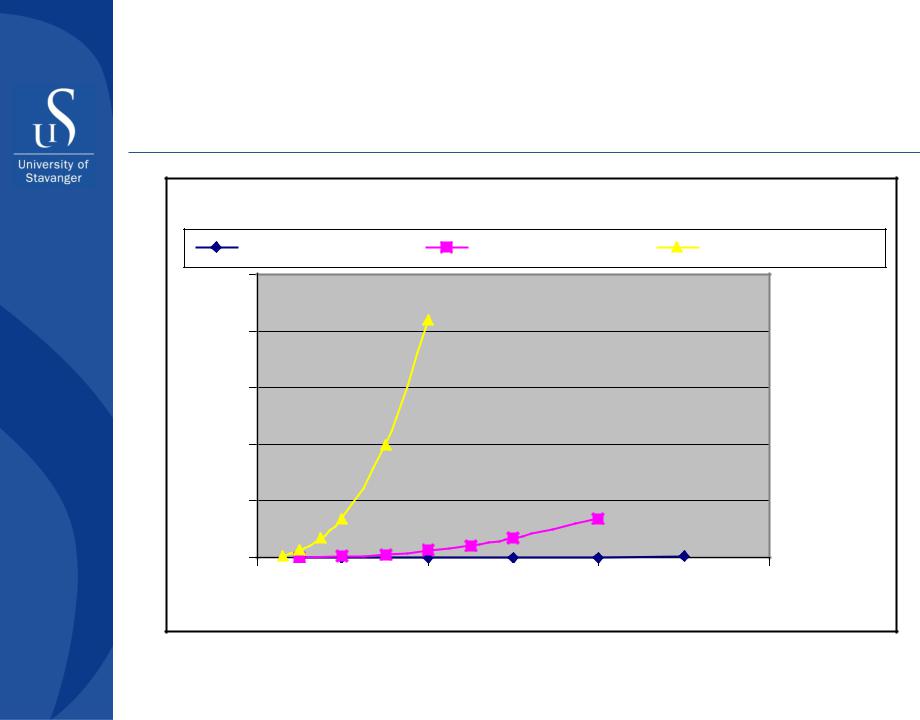

Erosion prediction for 6” pipe bend

|

|

WC=0, p=55bar, 1.5D bend, 0.3 mm particles |

||

|

GOR=100Sm³/Sm³ |

GOR=500Sm³/Sm³ |

GOR=1500Sm³/Sm³ |

|

|

0.5 |

|

|

|

sand) |

0.4 |

|

|

|

|

|

|

|

|

(mm/tonn |

0.3 |

|

|

|

0.2 |

|

|

|

|

Erosion |

|

|

|

|

0.1 |

|

|

|

|

|

|

|

|

|

|

0.0 |

|

|

|

|

0 |

2000 |

4000 |

6000 |

|

|

Production rate (Sm³/day oil+water) |

|

|

Part II - Well completion design