- •Syllabus

- •Well completion design

- •High Technology Wells

- •Production from oil rims

- •Intrawell gas lift

- •Alternating gas production

- •Improving sweep efficiency in a system of injection and production wells

- •Example

- •Problem setup

- •Drainage Strategy

- •Well completion scenario

- •Simulation Results: Cumulative oil production with ICVs and its incremental volumes as compared with ordinary completion wells

- •Discounted effect, ICVs performance

- •Position of ICV in one of the wells

- •Well perforation

- •Sand Control

- •Syllabus

- •Examples of developing materials with improved erosion resistance

Production from oil rims

Inflow profile to (a) conventional HW and (b) High Technology Well

In (a) well inflow profile distributed unevenly because of pressure drop along the well. As a result, earlier water and gas breakthrough in the heel region. In case (b) inflow profile is equalized.

a) |

|

|

Gas |

b) |

|

|

Gas |

|

|

|

|

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Oil rim |

|

|

|

|

|

|

|

|

|

Oil rim |

|||

|

|

|

|

|

|

|

|

Water  Water

Water

|

|

Pressure drop |

|

Pressure drop |

|||

|

|

||

|

|

||

|

|

|

Well length |

Well length |

Part II - Well completion design

Prepared by Alexey Khrulenko, 2010

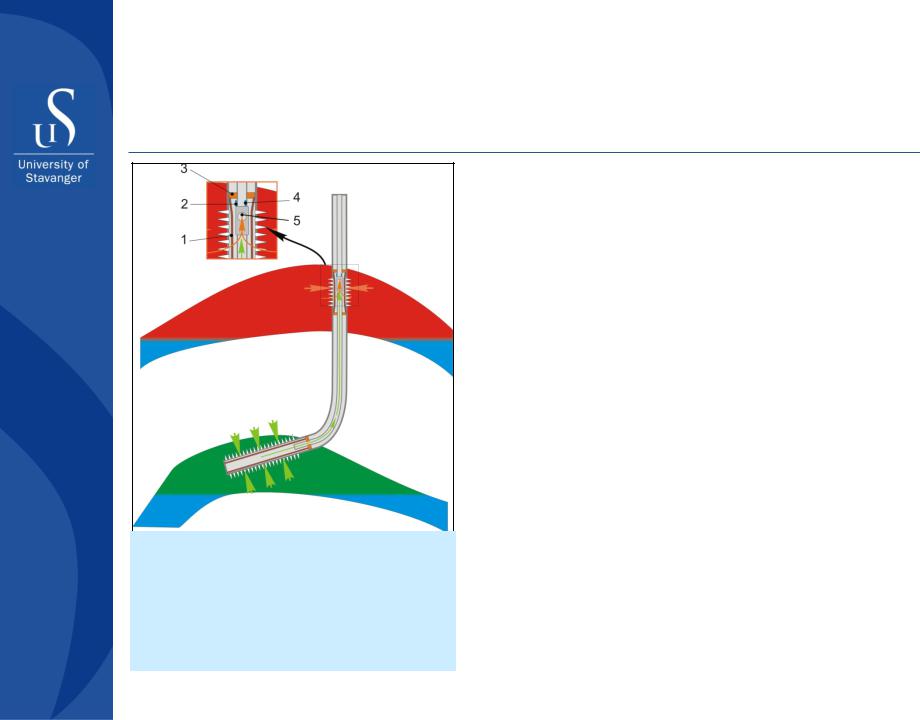

Intrawell gas lift

1.Gravel pack.

2.Pressure and temperature sensors on the outer side of production tubing;

3.Packers;

4.Pressure and temperature sensors on the inner side of production tubing;

5.ICV controlling gas rate to production tubing

Energy of gas cap is used to lift the oil

Examples of application:

Troll (Norsk Hydro, North Sea) – optimization of production from the oil rim

Abqaiq (Saudi Aramco) – securing the well flowing with high watercut

Fram Vest (Norsk Hydro, North Sea) – managing high well head pressure for increased oil production

Norne (Statoil, North Sea) – securing the subsea well flowing as an alternative to ESP or conventional gas lift application

Egret (Shell, Bruney shelf) – same + managing high well head pressure for stable transport of oil from subsea asset to a stationary platform

Part II - Well completion design

Prepared by Alexey Khrulenko, 2010

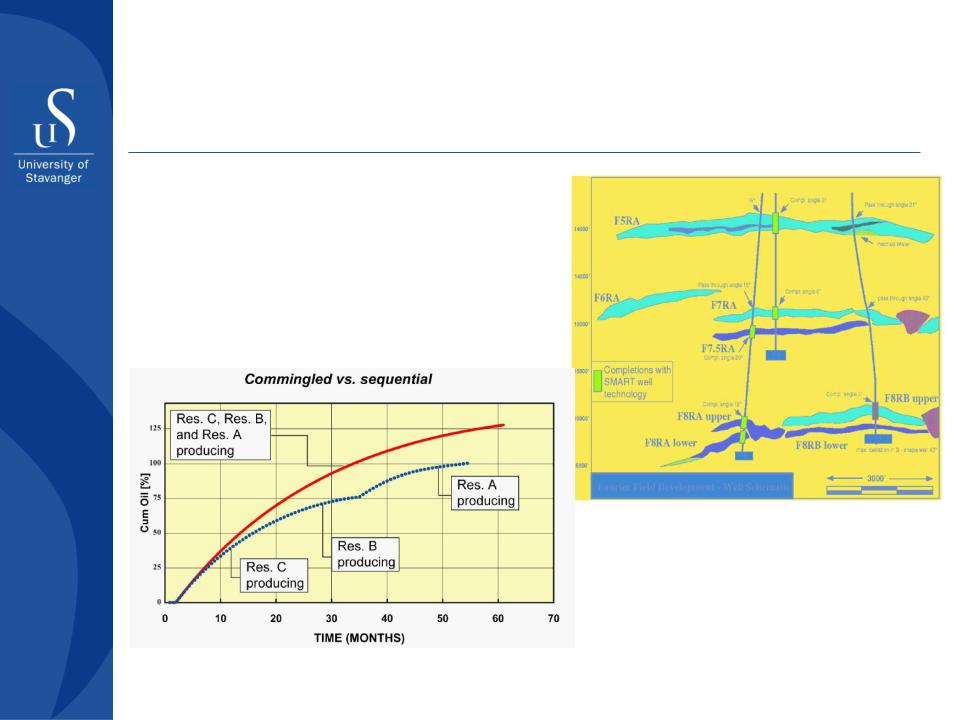

HTW: commingled production from 3 reservoirs, Na-Kika field, GOM

Vertical cross-section

Fourie field, Na-Kika project

Plots of cumulative oil production for commingled (red) and sequential (blue) production scenarios

September 21, 2013 |

PetParoleumtII - WellPolicycompletionand Operations,design |

30 |

|

PETRAD |

|

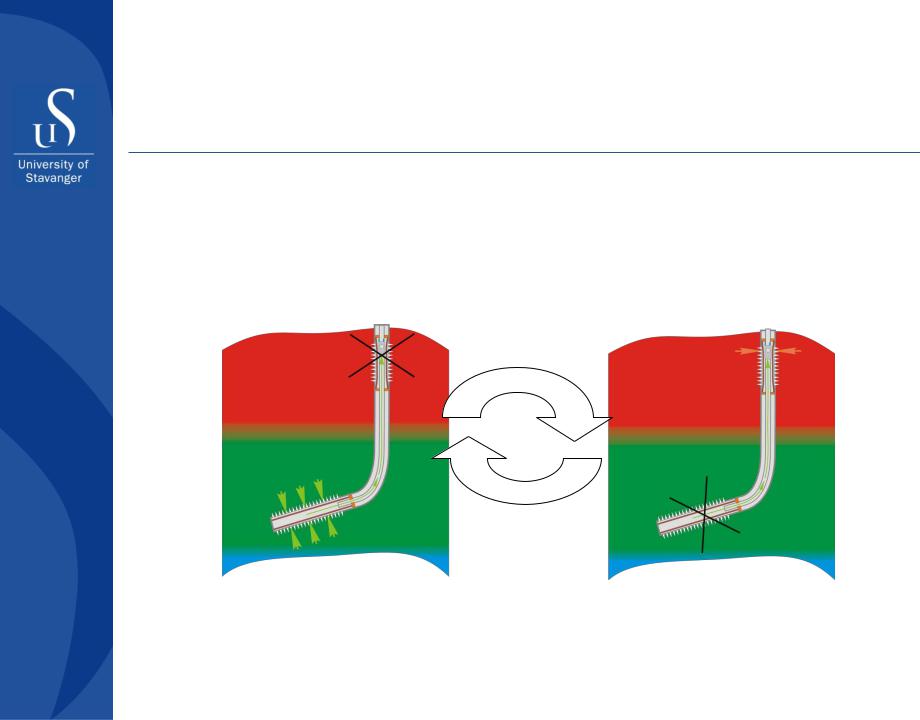

Alternating gas production

Layout is similar to that for intrawell gas lift. Used for securing increased gas production rates if required for a higher consumption. In this case deliverability of ICV to control production from the gas interval should be higher than required for the intrawell gas lift.

Oil production. Gas interval shut in |

Gas production. Oil interval shut in |

Examples of |

|

Vestflanken (Norsk Hydro, North Sea) |

application: |

|

Brent Charlie (Shell, North Sea) |

•Prepared by Alexey Khrulenko, 2010 |

Part II - Well completion design |