- •Syllabus

- •Well completion design

- •High Technology Wells

- •Production from oil rims

- •Intrawell gas lift

- •Alternating gas production

- •Improving sweep efficiency in a system of injection and production wells

- •Example

- •Problem setup

- •Drainage Strategy

- •Well completion scenario

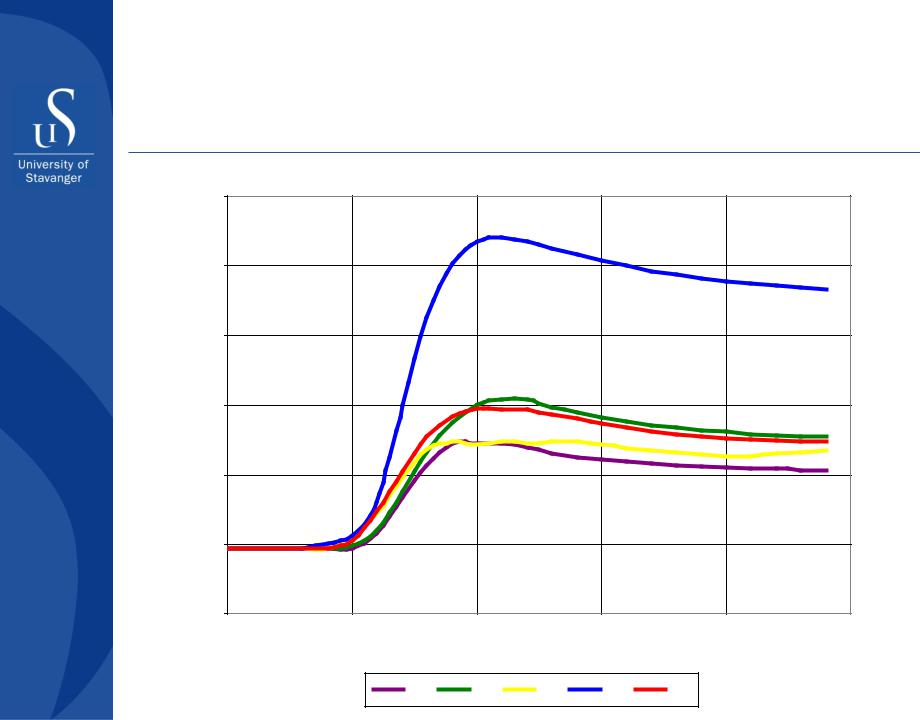

- •Simulation Results: Cumulative oil production with ICVs and its incremental volumes as compared with ordinary completion wells

- •Discounted effect, ICVs performance

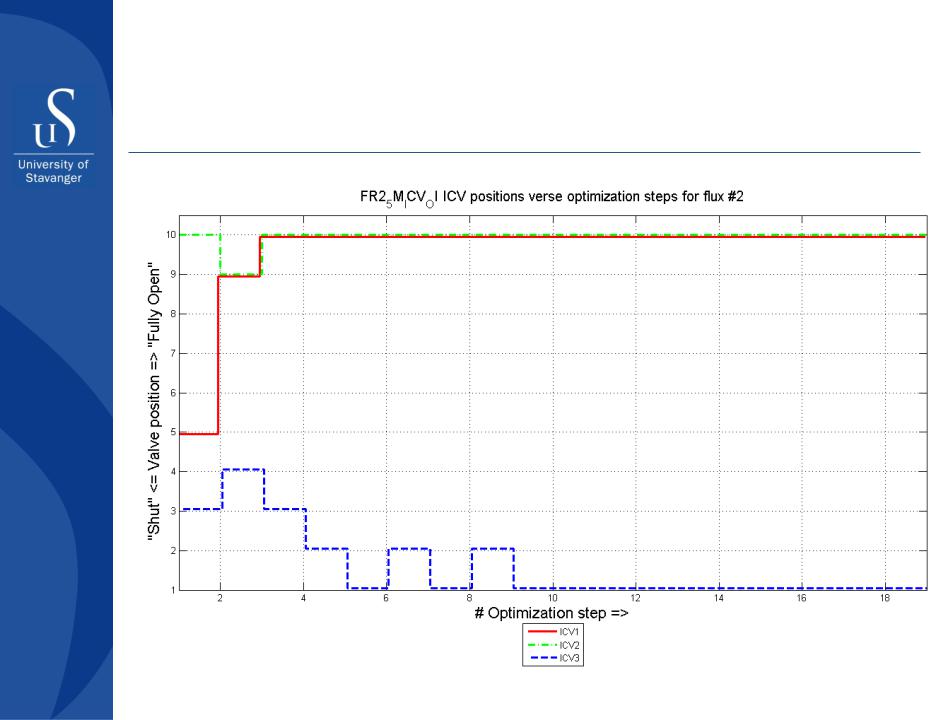

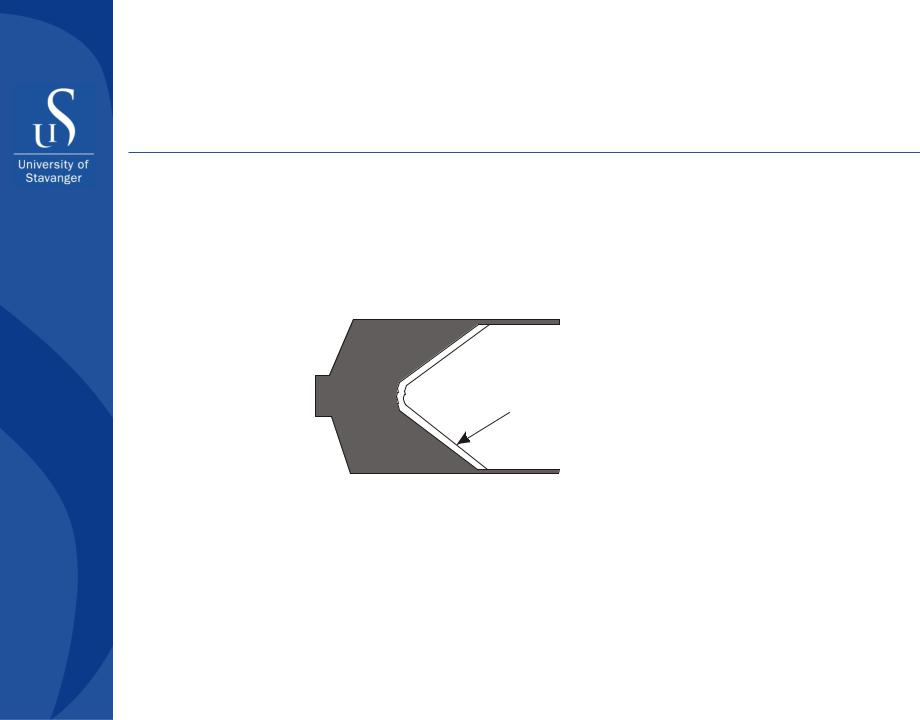

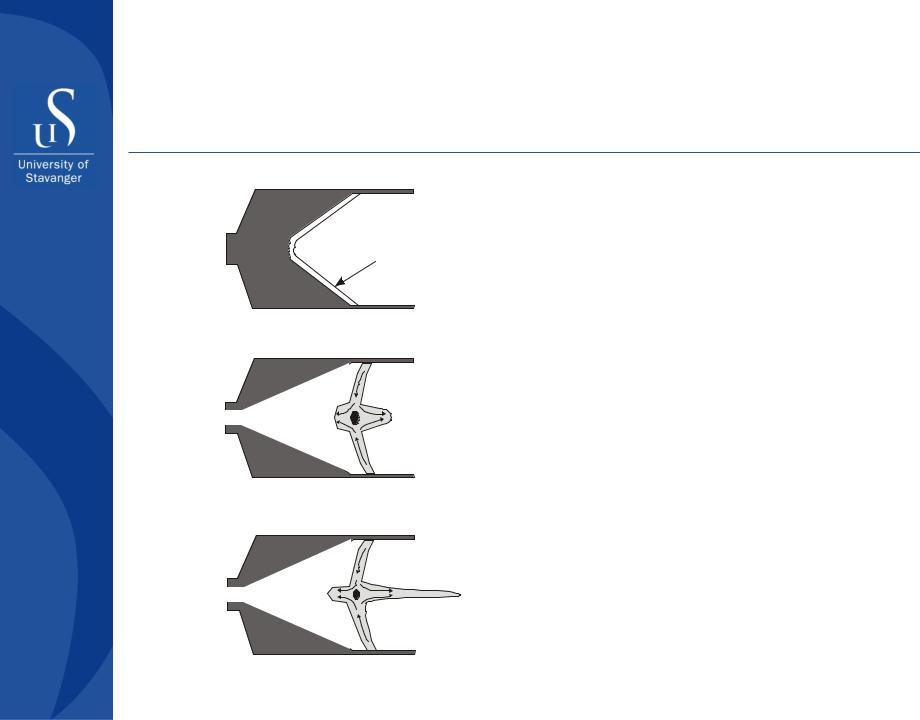

- •Position of ICV in one of the wells

- •Well perforation

- •Sand Control

- •Syllabus

- •Examples of developing materials with improved erosion resistance

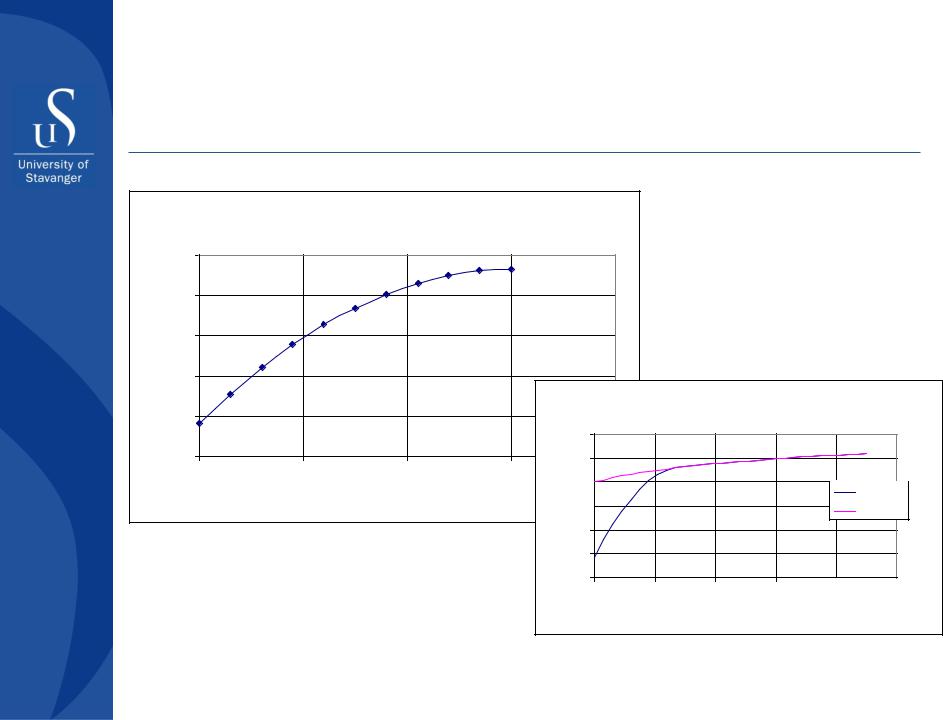

Discounted effect, ICVs performance

|

|

500 |

|

|

|

|

|

|

Дисконтированный•Discounted effect, $эффектmillion , |

|

400 |

|

|

|

|

|

|

|

300 |

|

|

|

|

|

|

|

млн. $ |

200 |

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

||

0 |

|

|

|

|

|

|

||

|

|

0 |

5 |

10 |

15 |

20 |

25 |

|

|

|

-100 |

|

|

|

|

|

|

|

|

|

|

• |

|

Time, years |

|

|

|

|

|

|

|

Время, лет |

|

|

|

•Prepared by Alexey Khrulenko, 2011

Part II - Well completion design |

#5 |

|||

#1 |

#2 |

#3 |

#4 |

|

Position of ICV in one of the wells

•Prepared by Alexey Khrulenko, 2011

Section 2

Well perforation

Part II - Well completion design

Well perforation

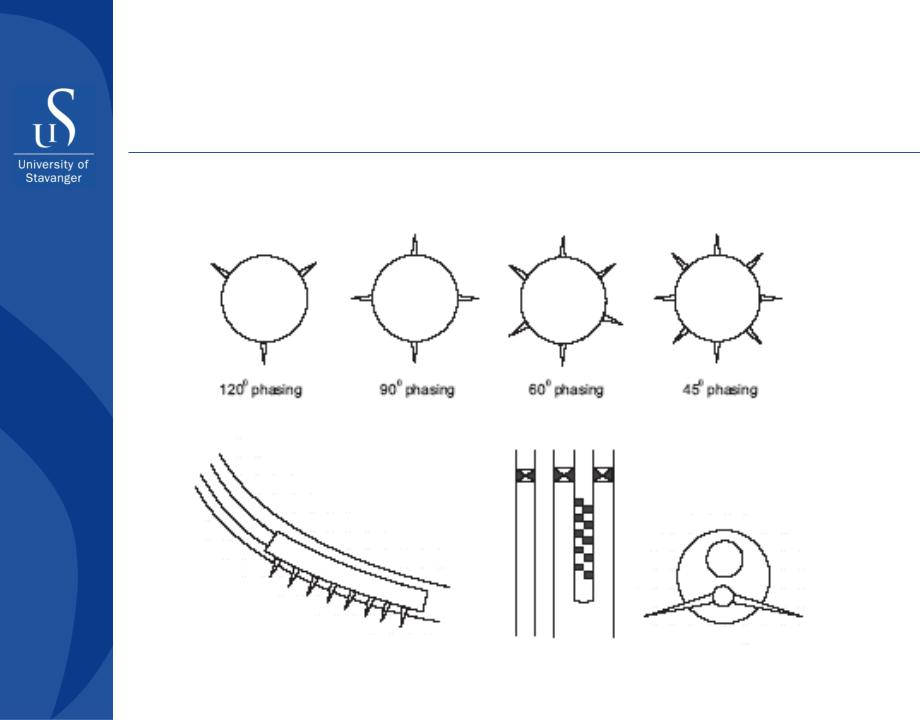

Perforation technique

Perforation design

Evaluating efficiency of perforation

−Depth of penetration

−Shot density

−Phasing

Part II - Well completion design

Well Perforation

Liner

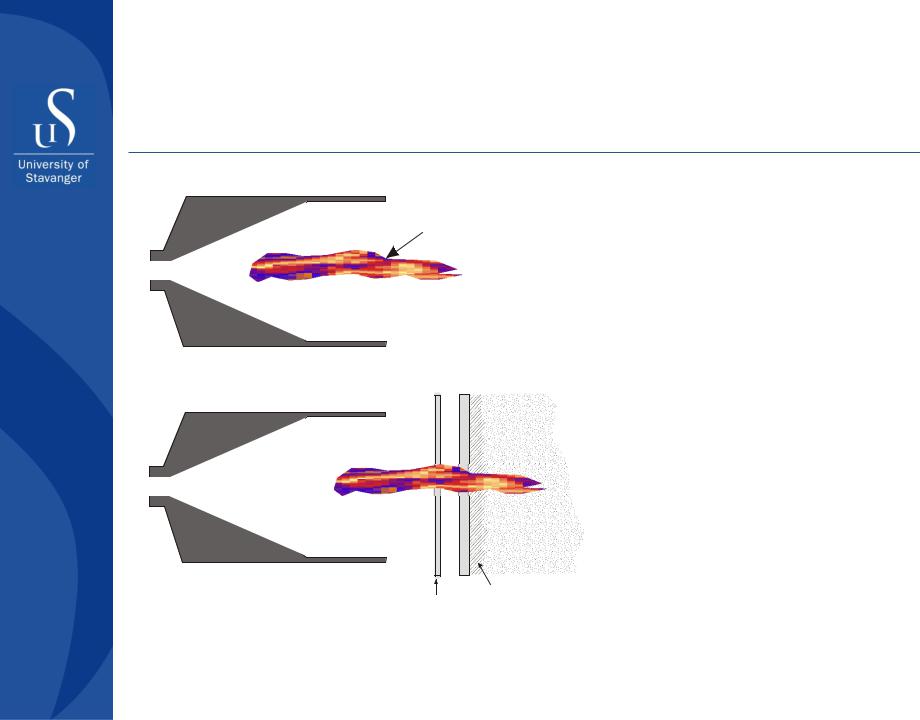

Part II - Well completion design

Well Perforation

Unfired shaped charge

Liner

Charge detonates.

Liner begins to collapse

High pressure jet forms.

Pressure wave with p=500000 bar travels at9000 km/hour

Part II - Well completion design

Well Perforation

Plasma jet

Jet becomes more developed. Pressure causes jet velocity to increase to 25000 km/hour

Jet is fully formed.

Tip of jet pierces and compacts the casing, cement, and formation

with 350000 bar

Formation

Hollow  Cement carrier Casing

Cement carrier Casing

Part II - Well completion design

Well Perforation

Perforation performance depends on a number of factors, among which most important are:

Charge type

Gun size

Shot density

Phasing

Conveyance method

Wellbore fluids

Part II - Well completion design

Well Perforation

Perforation cleaning

Failure to remove debris and compacted zone can reduce the potential productivity of a well as much as 80%!

The following methods can be used for perforation cleaning:

Acidizing

Washing

Backsurging

Underbalance perforating

Part II - Well completion design

Well Perforation

Perforation design

Important parameters of perforation design are:

Shot density

Shot phasing

Depth of perforation

Part II - Well completion design

Well Perforation

Perforation design

Part II - Well completion design

Well Perforation

|

Pressure distribution along the perforation tunnel |

|

|

|

|

|

|

|||||

|

175 |

|

|

|

|

|

|

|

|

|

|

|

|

170 |

|

|

|

|

|

|

|

|

|

|

|

bar |

165 |

|

|

|

|

|

|

|

|

|

|

pe=200 bar |

Pressure, |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

160 |

|

|

|

|

|

|

|

|

|

|

|

|

155 |

|

|

|

|

|

|

Pressure distribution within drainage area |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

180 |

|

|

|

|

|

|

|

150 |

|

|

|

bar |

175 |

|

|

|

|

|

|

|

0,00 |

0,05 |

0,10 |

0,15 |

170 |

0,20 |

|

|

|

Real well |

||

|

|

Length of perforation tunnel, cm |

Pressure, |

165 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

Ideal well |

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

155 |

|

|

|

|

|

|

|

|

|

|

|

|

150 |

|

|

|

|

|

|

|

|

|

|

|

|

0,10 |

0,20 |

0,30 |

0,40 |

0,50 |

0,60 |

|

|

|

|

|

|

|

|

|

|

Distance from wellbore, m |

|

|

|

Part II - Well completion design