- •Contents

- •About Getting Started Modeling Processes with Solids

- •Why Use Solids Simulation?

- •Sessions in this Book

- •Using Backup Files

- •Related Documentation

- •Installation Manual

- •User Guide

- •Technical Support

- •World Wide Web

- •Hours

- •Modeling Coal Drying

- •Coal Drying Flowsheet

- •Drawing the Graphical Simulation Flowsheet

- •Stream Classes and Substreams

- •Specifying Components

- •Defining Properties

- •For More Information on the HCOALGEN Model

- •Entering Stream Data

- •Specifying Blocks

- •Using a Calculator Block to Control Drying

- •Running the Simulation

- •Examining Simulation Results

- •Exiting Aspen Plus

- •Modeling Coal Combustion

- •Coal Combustion Flowsheet

- •Starting Aspen Plus

- •Opening an Existing Run

- •If Your Saved File Solid1.apw is Not Displayed

- •Saving a Run Under a New Name

- •Drawing the Graphical Simulation Flowsheet

- •Changing the Stream Class

- •Adding Components to the Model

- •Defining Properties

- •Change the Heat of Combustion Method for Coal

- •Specify the Heat of Combustion for Coal

- •Specifying the Air Stream

- •Specifying Unit Operation Models

- •Specify the Splits for the SSplit Block

- •Defining a Calculator Block

- •Specify the Calculations to be Performed

- •Specify When the Calculator Block Should be Run

- •Running the Simulation

- •Examining Results

- •Exiting Aspen Plus

- •Modeling Gas-Solid Separators

- •Gas-Solid Separation Flowsheet

- •Starting Aspen Plus

- •Opening an Existing Run

- •If Your Saved File Solid2.apw is Not Displayed

- •Saving a Run Under a New Name

- •Drawing the Graphical Simulation Flowsheet

- •To Update the Title for This Simulation

- •Running the Simulation

- •Examining Results

- •Exiting Aspen Plus

- •Modeling Polymer Recovery

- •Polymer Recovery Flowsheet

- •Starting Aspen Plus

- •To Specify the Application Type and Run Type for the New Run

- •Drawing the Graphical Simulation Flowsheet

- •Specifying Components

- •Defining Properties

- •Defining Stream Conditions

- •Entering Block Specifications

- •Enter Specifications for the CCD Model

- •To Learn More about the Cyclone Model Using Help

- •Enter Specifications for the Cyclone Model

- •To Specify That the Mixer Block DRIER Operates at 15 psi

- •Enter Specifications for the HyCyc Model

- •Running the Simulation

- •Examining Results

- •Exiting Aspen Plus

- •Connecting to the Aspen Plus Simulation Engine

Modeling Polymer Recovery

In this simulation you will model a simplified polymer washing and drying process.

You will use:

•Component attribute GENANAL to characterize a nonconventional (NC) component

•The hydrocyclone model (HyCyc)

•The counter-current decanter model (CCD)

•The cyclone model (Cyclone)

Allow about 30 minutes to do this simulation.

Getting Started - Solids |

Modeling Polymer Recovery • 5-1 |

Polymer Recovery Flowsheet

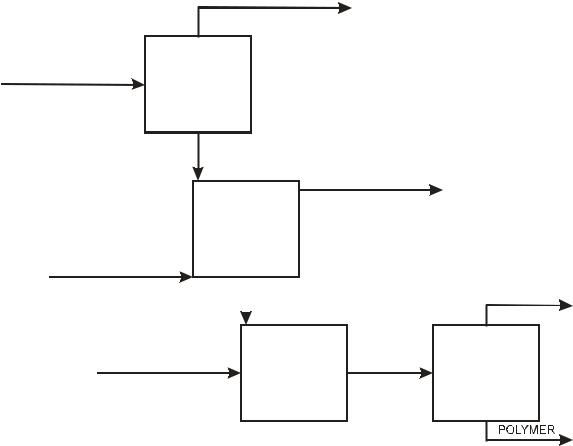

The process flow diagram and operating conditions for this simulation are shown in the following figure.

The feed stream FEED, a dilute slurry of polymer in acetone, is concentrated in a hydrocyclone. The concentrated slurry of polymer in acetone is then washed with water in a countercurrent decanter. The resulting slurry of polymer in water is dried with nitrogen. The gases from drying are separated from the solid polymer in a cyclone.

FEED

Pres = 16 psi Temp = 90 F

Acetone Flow = 1000 lb/hr Polymer Flow = 100 lb/hr

ACETONE

Eff = 0.95

for 100 microns

HCLONE

HYCYC

TO-CCD

WASH-OUT

WASH-H2O

Pres = 16 psi Temp = 200 F

H2O Flow = 400 lb/hr

CCD |

Pres = 15 psi |

|

|

|

3 stages |

CCD |

Mixing eff = 0.9 |

|

L/S ratio = 2.0 |

||

|

SLURRY |

|

|

|

|

|

|

|

HOT-N2 |

DRIER |

TO-CYCL |

|

||

Pres = 16 psi |

MIXER |

|

Temp = 350 F |

|

|

N2 Flow = 3000 lb/hr |

Pres = 15 psi |

|

|

|

VENT

CYCLONE

CYCLONE

Eff = 0.999

5-2 • Modeling Polymer Recovery |

Getting Started - Solids |