- •1. TABLE OF CONTENTS

- •2. BASIC MANUFACTURING

- •2.1 INTRODUCTION

- •2.2 PRACTICE PROBLEMS

- •3. MANUFACTURING COST ESTIMATING

- •3.1 COSTS ESTIMATES

- •3.2 COGS (COST OF GOODS SOLD)

- •3.3 VALUE ENGINEERING

- •3.4 REFERENCES

- •4. BASIC CUTTING TOOLS

- •4.1 CUTTING SPEEDS, FEEDS, TOOLS AND TIMES

- •4.2 HIGH SPEED MACHINING

- •4.3 REFERENCES

- •5. CUTTING THEORY

- •5.1 CHIP FORMATION

- •5.2 THE MECHANISM OF CUTTING

- •5.2.1 Force Calculations

- •5.2.1.1 - Force Calculations

- •5.2.1.2 - Merchant’s Force Circle With Drafting (Optional)

- •5.3 POWER CONSUMED IN CUTTING

- •5.4 PRACTICE QUESTIONS

- •5.5 TEMPERATURES IN CUTTING

- •5.6 TOOL WEAR

- •5.7 CUTTING TOOL MATERIALS

- •5.7.1 A Short List of Tool Materials

- •5.8 TOOL LIFE

- •5.8.1 The Economics of Metal Cutting

- •5.9 REFERENCES

- •5.10 PRACTICE PROBLEMS

- •6. SAWS

- •6.1 SPEEDS AND FEEDS

- •6.2 PRACTICE PROBLEMS

- •7. DRILLING

- •7.1 TYPES OF DRILL PRESSES

- •7.2 TYPICAL DRILL PRESS OPERATIONS

- •7.3 TYPICAL DRILL BITS

- •7.3.1 Reamers

- •7.3.2 Boring

- •7.3.3 Taps

- •7.4 DRILLING PROCESS PARAMETERS

- •7.4.1 The mrr For Drilling

- •7.5 PRACTICE PROBLEMS

- •8. LATHES

- •8.1 INTRODUCTION

- •8.2 OPERATIONS ON A LATHE

- •8.2.1 Machine tools

- •8.2.1.1 - Production Machines

- •8.3 LATHE TOOLBITS

- •8.3.1 Thread Cutting On A Lathe

- •8.3.2 Cutting Tapers

- •8.3.3 Turning Tapers on Lathes

- •8.4 FEEDS AND SPEEDS

- •8.4.1 The mrr for Turning

- •8.4.2 Process Planning for Turning

- •8.5 PRACTICE PROBLEMS

- •9. MILLING

- •9.1 INTRODUCTION

- •9.1.1 Types of Milling Operations

- •9.1.1.1 - Arbor Milling

- •9.1.2 Milling Cutters

- •9.1.3 Milling Cutting Mechanism

- •9.1.3.1 - Up-Cut Milling

- •9.1.3.2 - Down-Cut Milling

- •9.2 FEEDS AND SPEEDS

- •9.2.1 The mrr for Milling

- •9.2.2 Process Planning for Prismatic Parts

- •9.2.3 Indexing

- •9.3 PRACTICE PROBLEMS

- •10. GRINDING

- •10.1 OPERATIONS

- •10.2 MACHINE TYPES

- •10.2.1 Surface

- •10.2.2 Center

- •10.2.3 Centerless

- •10.2.4 Internal

- •10.3 GRINDING WHEELS

- •10.3.1 Operation Parameters

- •10.4 PRACTICE PROBLEMS

- •11. SURFACES

- •11.1 MEASURES OF ROUGHNESS

- •11.2 METHODS OF MEASURING SURFACE ROUGHNESS

- •11.2.1 Observation Methods

- •11.2.2 Stylus Equipment

- •11.2.3 Specifications on Drawings

- •11.3 OTHER SYSTEMS

- •11.4 PRACTICE PROBLEMS

- •11.4.0.1 - Roundness Testing

- •11.4.0.1.1 - Intrinsic Roundness Testing

- •11.4.0.1.2 - Extrinsic Roundness Testing

- •11.4.0.1.3 - Practice Problems

- •11.5 PRACTICE PROBLEMS

- •35. METROLOGY

- •35.1 INTRODUCTION

- •35.1.1 The Role of Metrology

- •35.2 DEFINITIONS

- •35.3 STANDARDS

- •35.3.1 Scales

- •35.3.2 Calipers

- •35.3.3 Transfer Gauges

- •35.4 INSTRUMENTS

- •35.4.1 Vernier Scales

- •35.4.2 Micrometer Scales

- •35.4.2.1 - The Principle of Magnification

- •35.4.2.2 - The Principle of Alignment

- •35.4.3 Dial Indicators

- •35.4.4 The Tool Makers Microscope

- •35.4.5 Metrology Summary

- •35.5 PRACTICE PROBLEMS

- •35.5.0.1 - Interferometry (REWORK)

- •35.5.0.1.1 - Light Waves and Interference

- •35.5.0.1.2 - Optical Flats

- •35.5.0.1.3 - Interpreting Interference Patterns

- •35.5.0.1.4 - Types of Interferometers

- •35.5.0.2 - Laser Measurements of Relative Distance

- •35.5.0.2.1 - Practice Problems

- •35.6 GAUGE BLOCKS

- •35.6.1 Manufacturing Gauge Blocks

- •35.6.2 Compensating for Temperature Variations

- •35.6.2.1 - References

- •35.6.3 Testing For Known Dimensions With Standards

- •35.6.3.1 - References

- •35.6.4 Odd Topics

- •35.6.5 Practice Problems

- •35.6.6 Limit (GO & NO GO) Gauges

- •35.6.6.1 - Basic Concepts

- •35.6.6.2 - GO & NO GO Gauges Using Gauge Blocks

- •35.6.6.3 - Taylor’s Theory for Limit Gauge Design

- •35.6.6.4.1 - Sample Problems

- •35.6.7 Sine Bars

- •35.6.7.1 - Sine Bar Limitations

- •35.6.7.1.1 - Practice Problems

- •35.6.8 Comparators

- •35.6.8.1 - Mechanical Comparators

- •35.6.8.2 - Mechanical and Optical Comparators

- •35.6.8.3 - Optical Comparators

- •35.6.8.4 - Pneumatic Comparators

- •35.6.9 Autocollimators

- •35.6.10 Level Gauges

- •35.6.10.1 - Clinometer

- •35.6.10.2 - The Brookes Level Comparator

- •35.6.11 The Angle Dekkor

- •35.7 MEASURING APARATUS

- •35.7.1 Reference Planes

- •35.7.1.1 - Granite Surface Plates

- •35.7.1.2 - Cast Iron Surface Plates

- •35.7.2 Squares

- •35.7.2.1 - Coordinate Measureing Machines

- •35.7.2.2 - Practice Problems

- •AM:35.7.3 Coordinate Measuring Machines (CMM)

- •36. ASSEMBLY

- •36.1 THE BASICS OF FITS

- •36.1.1 Clearance Fits

- •36.1.2 Transitional Fits

- •36.1.3 Interference Fits

- •36.2 C.S.A. B97-1 1963 LIMITS AND FITS(REWORK)

- •36.3 CSA MODIFIED FITS

- •36.4 CSA LIMITS AND FITS

- •36.5 THE I.S.O. SYSTEM

- •36.6 PRACTICE PROBLEMS

- •42. WELDING/SOLDERING/BRAZING

- •42.1 ADHESIVE BONDING

- •42.2 ARC WELDING

- •42.3 GAS WELDING

- •42.4 SOLDERING AND BRAZING

- •42.5 TITANIUM WELDING

- •42.5.1 Practice Problems

- •42.6 PLASTIC WELDING

- •42.7 EXPLOSIVE WELDING

- •42.7.1 Practice Problems

- •43. AESTHETIC FINISHING

- •43.1 CLEANING AND DEGREASING

- •43.2 PAINTING

- •43.2.1 Powder Coating

- •43.3 COATINGS

- •43.4 MARKING

- •43.4.1 Laser Marking

- •43.5 PRACTICE PROBLEMS

- •44. METALLURGICAL TREATMENTS

- •44.1 HEAT TREATING

- •44.2 ION NITRIDING

- •44.3 PRACTICE PROBLEMS

- •45. CASTING

- •45.1 SAND CASTING

- •45.1.1 Molds

- •45.1.2 Sands

- •45.2 SINGLE USE MOLD TECHNIQUES

- •45.2.1 Shell Mold Casting

- •45.2.2 Lost Foam Casting (Expandable Pattern)

- •45.2.3 Plaster Mold Casting

- •45.2.4 Ceramic Mold Casting

- •45.2.5 Investment Casting

- •45.3 MULTIPLE USE MOLD TECHNIQUES

- •45.3.1 Vacuum Casting

- •45.3.2 Permanent Mold Casting

- •45.3.2.1 - Slush Casting

- •45.3.2.2 - Pressure Casting

- •45.3.2.3 - Die Casting

- •45.3.3 Centrifugal Casting

- •45.3.4 Casting/Forming Combinations

- •45.3.4.1 - Squeeze Casting

- •45.3.4.2 - Semisolid Metal Forming

- •45.3.5 Single Crystal Casting

- •45.4 OTHER TOPICS

- •45.4.1 Furnaces

- •45.4.2 Inspection of Casting

- •45.5 Design of Castings

- •45.6 REFERENECES

- •45.7 PRACTICE PROBLEMS

- •46. MOLDING

- •46.1 REACTION INJECTION MOLDING (RIM)

- •46.1.1 References

- •46.2 INJECTION MOLDING

- •46.2.1 Hydraulic Pumps/Systems

- •46.2.2 Molds

- •46.2.3 Materials

- •46.2.4 Glossary

- •46.3 EXTRUSION

- •46.4 PRACTICE PROBLEMS

- •47. ROLLING AND BENDING

- •47.1 BASIC THEORY

- •47.2 SHEET ROLLING

- •47.3 SHAPE ROLLING

- •47.4 BENDING

- •48. SHEET METAL FABRICATION

- •48.1 SHEET METAL PROPERTIES

- •48.2 SHEARING

- •48.2.1 Progressive and Transfer Dies

- •48.2.2 DRAWING

- •48.3 DEEP DRAWING

- •48.4 SPINNING

- •48.5 MAGNETIC PULSE FORMING

- •48.6 HYDROFORMING

- •48.7 SUPERPLASTIC FORMING

- •48.7.1 Diffusion Bonding

- •48.8 PRACTICE PROBLEMS

- •49. FORGING (to be expanded)

- •49.1 PROCESSES

- •49.1.1 Open-Die

- •49.1.2 Impression/Closed Die

- •49.1.3 Heading

- •49.1.4 Rotary Swaging

- •50. EXTRUSION AND DRAWING

- •50.1 DIE EXTRUSION

- •50.1.1 Hot Extrusion

- •50.1.2 Cold Extrusion

- •50.2 HYDROSTATIC EXTRUSION

- •50.3 DRAWING

- •50.4 EQUIPMENT

- •50.5 PRACTICE PROBLEMS

- •51. ELECTROFORMING

- •51.1 PRACTICE PROBLEMS

- •52. COMPOSITE MANUFACTURING

- •52.1 FIBER REINFORCED PLASTICS (FRP)

- •52.2 COMPOSITE MANUFACTURING

- •52.2.1 Manual Layup

- •52.2.2 Automated Tape Lamination

- •52.2.3 Cutting of Composites

- •52.2.4 Vacuum Bags

- •52.2.5 Autoclaves

- •52.2.6 Filament Winding

- •52.2.7 Pultrusion

- •52.2.8 Resin-Transfer Molding (RTM)

- •52.2.9 GENERAL INFORMATION

- •52.2.10 REFERENCES

- •52.2.11 PRACTICE PROBLEMS

- •53. POWDERED METALLURGY

- •53.1 PRACTICE PROBLEMS

- •54. ABRASIVE JET MACHINING (AJM)

- •54.1 REFERENCES

- •54.2 PRACTICE PROBLEMS

- •55. HIGH PRESSURE JET CUTTING

- •56. ABRASIVE WATERJET CUTTING (AWJ)

- •57. ULTRA SONIC MACHINING (USM)

- •57.1 REFERENCES

- •57.1.1 General Questions

- •58. ELECTRIC DISCHARGE MACHINING (EDM)

- •58.1 WIRE EDM

- •58.2 PRACTICE PROBLEMS

- •58.3 REFERENCES

- •59. ELECTROCHEMICAL MACHINING (ECM)

- •59.1 REFERENCES

- •59.2 PRACTICE PROBLEMS

- •60. ELECTRON BEAM MACHINING

- •60.1 REFERENCES

- •60.2 PRACTICE PROBLEMS

- •61. ION IMPLANTATION

- •61.1 THIN LAYER DEPOSITION

- •61.2 PRACTICE PROBLEMS

- •62. ELECTROSTATIC SPRAYING

- •62.1 ELECTROSTATIC ATOMIZATION METHOD

- •62.2 PRACTICE PROBLEMS

- •63. AIR-PLASMA CUTTING

- •63.1 REFERENCES

- •63.2 PRACTICE PROBLEMS

- •64. LASER CUTTING

- •64.1 LASERS

- •64.1.1 References

- •64.2 LASER CUTTING

- •64.2.1 References

- •64.3 PRACTICE PROBLEMS

- •65. RAPID PROTOTYPING

- •65.1 STL FILE FORMAT

- •65.2 STEREOLITHOGRAPHY

- •65.2.1 Supports

- •65.2.2 Processing

- •65.2.3 References

- •65.3 BONDED POWDERS

- •65.4 SELECTIVE LASER SINTERING (SLS)

- •65.5 SOLID GROUND CURING (SGC)

- •65.6 FUSED DEPOSITION MODELLING (FDM)

- •65.7 LAMINATE OBJECT MODELING (LOM)

- •65.8 DIRECT SHELL PRODUCTION CASTING (DSPC)

- •65.9 BALLISTIC PARTICLE MANUFACTURING (BPM)

- •65.9.1 Sanders Prototype

- •65.9.2 Design Controlled Automated Fabrication (DESCAF)

- •65.10 COMPARISONS

- •65.10.1 References

- •65.11 AKNOWLEDGEMENTS

- •65.12 REFERENCES

- •65.13 PRACTICE PROBLEMS

- •66. PROCESS PLANNING

- •66.1 TECHNOLOGY DRIVEN FEATURES

- •66.2 MOST SIGNIFICANT FEATURE FIRST

- •66.3 DATABASE METHODS

- •66.4 MANUFACTURING VOLUMES

- •66.5 STANDARD PARTS

- •66.6 PRACTICE PROBLEMS

- •66.6.1 Case Study Problems

- •66.6.1.1 - Case 1

- •66.7 REFERENCES

page 469

- etc.

66.5 STANDARD PARTS

•Purchased components are typically well designed and inexpensive.

•When you do not have experience designing or manufacturing a certain component, and volumes are low, it may not be possible to produce components at a lower cost than they can be produced.

•These parts must still be considered in the process plans so that they are orders, and arrive in suitable forms.

66.6 PRACTICE PROBLEMS

1.A block of metal 5” by 5” by 5” will be milled to 5” by 5” by 4” and then will have two separate holes drilled 2” deep. The hole will be finished with a reamer.

Part: - Mild Steel Drilling:- High speed steel

-15/32” diameter

-C.S. = 80 ft/min.

-feed = .010” per revolution

-setup time = 5 min. per part

-cost is $40.00 per hour

Reaming:- Carbide Steel

-1/2” diameter

-C.S. = 60 ft./min.

-feed = .015” per revolution

-setup time = 2 min. per hole

-cost is $45.00 per hour Milling:- High speed steel

-C.S. = 100 ft./min.

-cutter diameter = 1”

-10 teeth with a tooth load of .004” per tooth

-setup time = 1 min. per part

-cost is $47.50 per hour

a)Estimate the machining time required to make 50 parts.

b)Estimate the cost of the 50 parts.

c)Estimate the machine horse power required for the drill, reamer and the mill.

2.Calculate the machine tool spindle speeds for the following:

page 470

a)Milling with a tungsten carbide tipped face cutter on a stainless steel work piece. C.S. = 65 m/min., cutter dia. = 150mm.

b)Drilling with a High Speed Steel drill in Machine Steel work, with C.S. = 70 ft./min., and a drill diameter of 19/32”

c)Turning on a lathe with a High Speed Steel tool in a mild steel work piece. Surface cutting speed = 100 ft./min., and a workpiece diameter of 2.75”

d)Milling with a High Speed Steel cutter in tool steel work with a cutter speed of 60 ft./ min., and a cutter diameter of 3/4”.

3.The part below has three turned diameters, on one end there is a square tang that has been milled. The part is made of aluminum. (Note: R indicates radius)

R1.00”

R0.75”

R0.30”

0.25”

0.75” |

|

|

|

|

|

|

|

|

|

1.20” |

2.30” 0.50”

0.25”

a)Write a process plan that describes the operations necessary to produce the part.

b)If the milling cutter is a 1/2” diameter end mill with 6 teeth, determine a reasonable feed and speed for cutting the tang.

c)What are reasonable speeds and feeds for turning the part for rough and finish turning? (Note: pick one cut for your calculations)

page 471

ans. |

a) |

0010 Cutoff stock with dia. 2 1/4” by 4” |

|

|

|

0020 |

Mount 0.75” in 3 jaw chuck |

|

|

0030 |

Face end and turn down to 2” dia. for 2.8” |

|

|

0040 |

Turn in chuck and face to length |

|

|

0050 |

Cut the taper with a taper cutting attachment |

|

|

0060 |

Use a slot cutter to cut the 0.25” slot 0.4” below the taper |

|

|

0070 Mount upright in vise in mill |

|

|

|

0080 |

Use endmill to cut around the tang |

|

|

500 + 1000 |

ft |

|

|

|

|

|

b) |

CS = |

--------------------------2 |

|

-------- |

fpt = 0.011in |

|

||

= 750min |

|

|||||||

|

RPM = |

12CS |

= 5730 |

F = fpt( teeth) RPM = 378 in |

||||

|

-------------π D |

|||||||

|

|

|

|

|

|

|

|

min |

c) |

Rough |

|

|

|

Finish |

|

|

|

|

|

|

|

|

|

|

||

|

|

ft |

|

|

|

ft |

|

|

|

CS = 200min-------- |

|

|

|

-------- |

|

|

|

|

|

|

CS = 300min |

|

|

|||

|

0.015 + 0.030 |

in |

0.005 + 0.010 |

in |

||||

|

F = -------------------------------- |

2 |

|

= 0.023 rev------ |

F = -------------------------------- |

2 |

|

= 0.008rev------ |

|

RPM = |

12-------------CS |

= 382 |

RPM = |

12-------------CS |

= 573 |

||

|

|

π D |

|

|

|

π D |

|

|

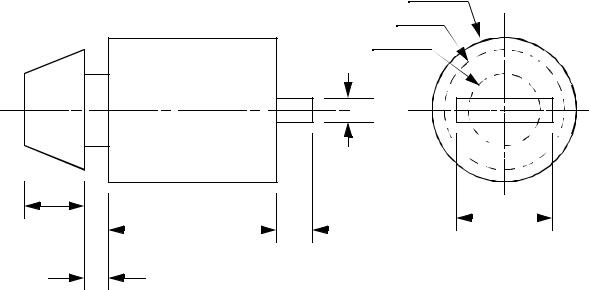

4. Develop a process plan for the part below. You should include speeds, feeds and times. Hint: The part will be easy to make if a combination of milling, drilling and turning is used.

R1.75” |

|

|

Hole bored to 1.50” depth |

||||||||||||||

R1.25” |

|

|

1.00” |

|

|

|

|

|

|||||||||

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.00” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

1.00” |

||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.50” |

4.00” |

|

Mat’l aluminum

5.00”