SpeakingOilGas

.pdfAcidising and fraccing

There are times when logs and testing techniques indicate that oil and/or gas is present in a reservoir, but the formation is not permeable enough to readily allow hydrocarbon flow.

If the reservoir is a limestone or a dolomite, an acid solution can be pumped down the well and forced into the formation. The acid etches into the carbonate rocks of the reservoir around the well, opening up channels and unlocking the hydrocarbons.

If the reservoir is a sandstone with low permeability, the formation can be forced open by pumping a specially blended fluid (chemicals that don’t adversely react with the formation, even air and inerts like nitrogen) under great pressure downhole and into the formation until it literally cracks it open. The pumping pressure exceeds the formation strength. This technique is known as fracture stimulation or fraccing. Proppants mixed in with the fluid (such as sand, aluminium pellets, even walnut shells in the early days) are also forced into the formation and they keep the new fractures open so that a path remains for hydrocarbons to flow to the well.

Abandonment or completion

If a well is dry, or if hydrocarbons found are non-commercial, the well is plugged and abandoned (P&A). This process calls for isolating various formations with cement, taking particular care to block the reservoir zones and any high pressure zones that may have been encountered.

Sometimes wells are suspended by setting cement plugs as a temporary seal. At a later date the well may be re-entered for evaluation and the cement plugs are simply drilled out using standard drilling techniques.

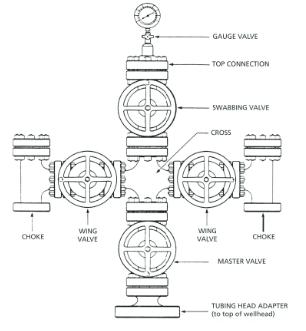

If the well has tested commercial hydrocarbons, it is usually completed as a producing well or suspended so that completion can be carried out at a later date. A completed well has production tubing installed and the well casing is perforated in the reservoir zone. A system of valves (known as a Christmas tree) is placed at the wellhead on the surface for later hook-up to the production system.

66 |

SPEAKING OIL & GAS |

Typical Christmas tree

Offshore a successful well is often plugged and abandoned because it is not optimally placed for future development. Development drilling will be done later from one or two platforms at other locations on the field, selected for ensuring an even drainage of the reservoir. The exception is for small fields offshore where subsea completions may be installed on each successful well, or where single-well platforms are used. In those cases the original exploration wells may be used as production wells.

Remedial work

Few wells are textbook operations in practice and any number of problems can be encountered during drilling or testing.

DRILLING |

67 |

Some of these include the drill pipe sticking in the hole, twisting off a section of drill pipe in the hole, the loss of equipment such as logging or test tools down the hole, washouts and loss of mud circulation into the formation and, most serious of all, formation fluids overcoming drilling mud pressure causing blowout and possible fire, explosion and equipment damage at the surface.

When there is a stuck pipe or equipment is dropped or sheared off downhole, the operator has three alternatives. They can fish for the obstruction with specially designed grappling, cutting, grinding and magnetic tools. Another option is to drill around the obstruction by deviating from a point a little above it (sidetracking). However, if a sidetrack is also likely to be difficult, the operator may decide on the third (albeit very expensive) alternative — drill a completely new well from the surface.

Loss of circulation and washouts in soft formation can also be difficult to contain and often the well program must be changed so that casing is run through the troublesome section earlier than originally planned. Recently a way around this dilemma has been provided by the development of ‘expanding casing’ which is made of very pure steel. Once in position over a bad patch in the well, a cone is pushed down through it to open out the diameter. This avoids the need to set the next casing size and thereby lose diameter for the next part of the hole.

An increase in the density of mud weight, and blowout equipment in working order, can usually overcome any sudden pressure inflows in a well. In such events too, a lot depends on the experience of the drilling personnel. A crew trained in well control and blowout prevention can circulate a kick of high pressure out of the system using the valves and chokes in the well.

Another form of remedial operation is the well workover. This can either be a program of widening, cleaning or re-perforating an old abandoned well, or a producing well that has already had a long life and needs rejuvenating. The workover is usually carried out with a small drilling rig on land and on a production platform, or one of the four types of offshore rigs suitable for an offshore location.

68 |

SPEAKING OIL & GAS |

Chapter 4.

EVALUATION & PRODUCTION

Evaluation of a discovery is still, strictly speaking, an exploration function and involves detailed appraisal work.

Reserves estimates

Once exploration drilling has discovered an oil and gas accumulation, appraisal drilling is needed to determine whether or not it is large enough to be commercially viable. As the drilling results come in, the geological/ reservoir engineering team makes an evaluation of the discovery and an estimate of the reserves. Naturally enough, the more well data collected, the more confidence can be placed in the estimate.

EVALUATION & PRODUCTION |

69 |

Appraisal

Appraisal wells are sited to determine the physical parameters or dimensions of the field. For instance, if the discovery well has successfully penetrated the crest of a structure, the appraisal wells will probably be drilled down the flank to establish the lateral extension in four directions by finding the oil/water contact. If the discovery well has penetrated a structural flank and already established an oil/water contact, then there is scope to drill an appraisal well closer to the crest (or up-dip) to try and find a gas/oil contact point. This can indicate the true height of the highest and lowest point of oil in the structure (the hydrocarbon interval or pay zone). Sometimes oil may not have a gas cap and this can be determined by drilling on the top (crest) of the structure. A purely gas reservoir will be indicated if the appraisal finds a gas/water contact.

Appraisal work includes input from seismic mapping, downhole log data and well tests. The results are used to determine the oil/gas, oil/water and/or gas/water contacts and to indicate the horizontal and vertical dimensions of the trap. This in turn, enables an estimation to be made of the potential volume of oil and/or gas in place (in situ). However, the calculations are rarely straightforward. Complications arise through errors or uncertainties in seismic interpretation, faulting, lithological changes and erosional features. A general rule is: the thicker the pay zone, the more continuous it is likely to be. But this is by no means absolute.

Three other factors of major importance are net pay, porosity and hydrocarbon saturation.

Net pay thickness in the reservoir or reservoirs is the interval filled with hydrocarbons, and is generally derived from core or cuttings and logs or interpretations from test results.

Porosity is the capacity of a given volume of the reservoir to hold fluids. An estimate is made from the well logs and core analysis.

Hydrocarbon saturation is also derived from well logs and is the fraction of the porosity that is hydrocarbon filled. The degree of confidence in the estimate varies with the type of lithology, the type and quality of the logs and the availability of data from previous wells in the area.

70 |

SPEAKING OIL & GAS |

Once the physical shape of the accumulation and volume of hydrocarbons in situ are known, it is possible to estimate the reserves (the proportion of hydrocarbons expected to be commercially recovered from the reservoir). Due to the nature of the fluids, uncertainties in knowledge of the reservoir parameters and the limited number of wells that will be drilled, recovery is always much less than 100 per cent. For an oil field, recovery will generally be 10–40 per cent, but it can in exceptional circumstances reach 70–80 per cent. Gas recovery is normally 50–80 per cent of the hydrocarbons in situ.

Recovery estimates

The so-called recovery factor, which denotes the percentage of hydrocarbons in situ that will be recoverable, depends on three main items — nature of the fluid, reservoir drive mechanism and productivity.

The nature of the oil or gas in a reservoir is described by chemical analysis of its components. For oil, measurements of the API gravity value, the pour point (the temperature at which oil changes from liquid to solid), the bubble point (the point, during decreasing pressure, at which gas begins to come out of solution with the oil), the viscosity and the gas/oil ratio (GOR) are also relevant.

The drive mechanism of the reservoir is the availability of natural means of supporting the pressure in the reservoir. There are three common types:

•A water drive occurs when water in the reservoir formation is directly in contact with the oil (or gas). As oil (or gas) is produced, pressure in the reservoir is reduced causing an influx of the water, which in turn sweeps through the pores of the rock and pushes the oil (or gas) out as it advances.

•A solution gas drive occurs where pressure support is provided solely by the oil. The drop in pressure caused by production releases gas from solution in the oil. As the gas expands, it displaces an increasing quantity of oil from the pores.

EVALUATION & PRODUCTION |

71 |

•A gas cap drive occurs when there is a large gas cap in direct communication with an oil zone. As the pressure is reduced, the gas cap expands and sweeps oil ahead of it.

Often the drive mechanism is a combination of these and other mechanisms. Water drive is the most favourable and solution gas is the least favourable. In all cases, pressure, and therefore production, declines with time.

Productivity is often the least predictable parameter. It is mainly a function of the reservoir permeability and fluid viscosity. It can be determined in part from cores and interpretation of test results.

Reserves classification

Common terms used when describing petroleum reserves in a field are proved, probable and possible. They reflect the confidence that is felt about the reserves calculated. Proved reserves reflect a very high degree of confidence (90 per cent certainty and labelled P1 reserves). At the other end of the scale possible reserves have a very low degree of confidence attached to them (10 per cent certainty or P3 reserves). Probable reserves represent the mid-range of confidence (50 per cent certainty, or P2).

Companies sometimes also use a slightly confusing notation — 1P, 2P and 3P — when reporting reserve figures. Taken respectively these simply mean proved reserves only, proved plus probable reserves, and the sum of proved plus probable plus possible reserves.

Market potential

Modern field evaluation techniques also include preliminary marketing investigations. For oil discoveries, the field operator will run a detailed assay to determine the exact nature of the crude, including a breakdown of its components and the type of petroleum products that may be obtained when it is refined. This step is also a check for any impurities in the crude that need to be dealt with to comply with companies’ strict health and safety programs, as well as to give an early start in establishing plans for their removal during any development stage. The assays are done on samples obtained upon discovery and during appraisal drilling.

72 |

SPEAKING OIL & GAS |

The assay results are circulated to potential buyers to gauge interest and the possibilities for sale, if and when the field is brought on stream.

For gas, assays to determine the nature and percentage of the components (including any impurities such as carbon dioxide, nitrogen and sulphur compounds) are an important factor in establishing economic value. However, it is usual when dealing with gas accumulations to establish a market before development can take place. Hence an initial market evaluation, domestically and internationally, is often carried out in conjunction with field appraisal work.

In some instances the results of market surveys can influence the nature of development plans and the design of the production facilities.

Once the reserves for a field are estimated and declared viable, planning for development can begin. Sometimes the go-ahead to proceed to development will be given immediately. At other times a more cautious, stepped approach is taken which involves preliminary design (or feasibility studies) followed by a front end engineering and design (FEED) stage. The FEED stage provides definitive costs and technical data to enable a decision on whether or not to make a final commitment to finance a full development plan.

Development drilling

Offshore, petroleum engineers draw on their knowledge of the field gained during the evaluation (aided by the computer-generated models based on the acquired data) to choose an optimum number of well locations to effectively and efficiently drain the reservoir across the whole field. Generally these wells must be identified prior to actual development to permit proper design of the facilities. Wells can be vertical, deviated or horizontal and may be drilled from one or more central platform locations. Sometimes well slots on a platform are not used immediately. Rather, those wells are drilled at a later date when the engineers have some idea of the field’s production history. For instance, they may be directed into spots in the reservoir where oil has been left behind, or to boost production from an area that is flagging. Development wells can also be individual subsea completions and in this case it is often possible to re-use exploration wells as subsea production wells.

EVALUATION & PRODUCTION |

73 |

In the onshore sector, development drilling generally occurs in a more step-wise fashion. Additional wells are committed to and drilled only after the results of earlier wells are known. There is less need to commit to a full field development at the very beginning. Wells are often vertical, although recent perfection of the horizontal drilling technique and the use of motorised bits has provided this option for use particularly in thin reservoirs. In onshore work it is generally possible to use successful exploration wells as producers.

Improved technology is blurring the former distinction between offshore and onshore development because some offshore fields can also be developed in a step-by-step progression using subsea completions and monopod platforms as an initial guide to future development options. Nevertheless, whether onshore or offshore, the number and spacing of wells will be determined by reservoir parameters, the field size and, particularly in the case of gas, the commercial contract requirements.

Information obtained from development drilling improves the reliability of reserve estimates and further improvements occur as the field is produced.

Production techniques

Field production comes under three main headings — primary, secondary (or supplementary) and tertiary (or enhanced) recovery.

In primary recovery the reservoir pressure (drive mechanism) forces oil and gas to the well and hence to the surface under natural flow. Some fields may have several producing horizons, each with a different pressure, petroleum type and other variables that need separate production. This can be accomplished with separate wells. Alternatively, a dual or multiple completion can be established in the one well.

The latter methods are mechanically more complex and therefore more difficult to maintain, despite the fact that they are cheaper to install than drilling second and third wells using single completions in each zone.

74 |

SPEAKING OIL & GAS |

A beam pump unit (nodding donkey)

EVALUATION & PRODUCTION |

75 |